Three-stage circulation aerobic reactor

A technology of aerobic reaction zone and circulating return system, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc. The effect of strong shock load resistance, high processing efficiency and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

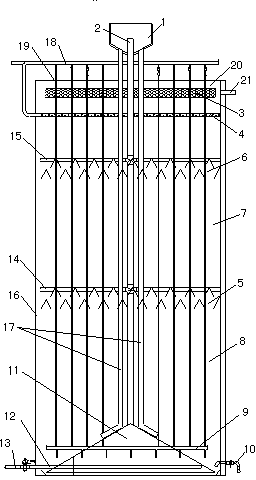

[0011] As shown in the accompanying drawings, the three-cycle aerobic reactor of the present invention mainly includes a columnar pool body 16, the pool body 16 adopts a steel structure, and the entire structure is columnar, which is a multi-region and multi-functional combination. In the pool body 16, from bottom to top, there are conical sludge expansion zone 11, aerobic reaction zone 8, primary gas-solid-liquid separation zone 5, anoxic reaction zone 7, secondary gas-solid-liquid separation zone 6 and sediment filtration zone. Layer 3. The conical sludge bulking zone 2 is a conical hood, and a stripping pipe 2 is connected to the conical hood. A water outlet weir 20 is arranged above the sedimentation filter layer 3 , and a water outlet pipe 21 is arranged on the water outlet weir 20 .

[0012] The top of the pool body 16 is provided with a gas-liquid separation tank 1, and the gas-liquid separation tank 1 is connected with a gas-lift pipe 2 and a lower return pipe 17. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com