Electrostatic spinning receiving device

A receiving device and electrospinning technology, which is applied in the direction of textiles and papermaking, and the clustering of newly sprayed filaments, etc., can solve the problems that cannot be removed effectively, are difficult to volatilize naturally, and become cast films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

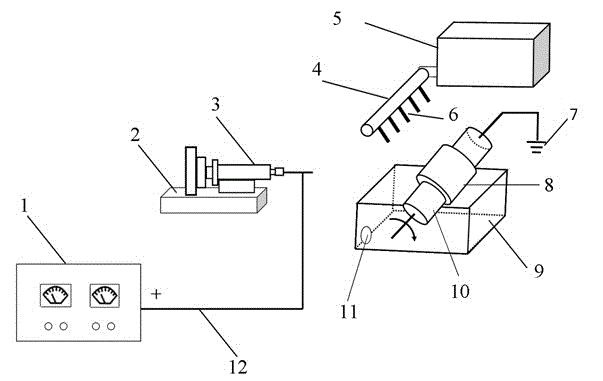

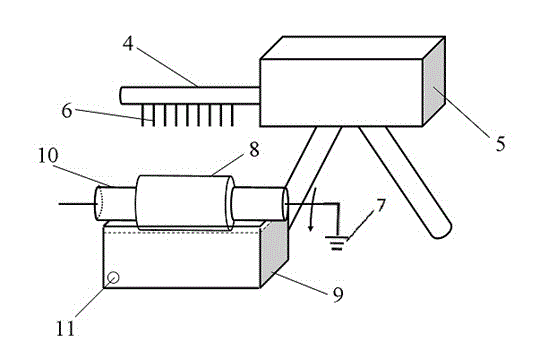

[0010] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0011] Such as figure 2 As shown, the electrospinning receiving device of the present invention includes: a water pipe 4 , a water tank 5 , a needle 6 , a ground electrode 7 , a non-woven wet wipe 8 , a circulating water tank 9 and a drum 10 . Among them, the water tank 5 is above the circulating water tank 9, the water pipe 4 communicates with the water tank 5, a plurality of needles 6 are fixed on the water pipe 4, the drum 10 is placed on the circulating water tank 9, and the drum 10 is wrapped with non-woven fabric wet wipes 8, and the drum 10 is connected to the ground. The electrodes 7 are connected to each other, and the circulating water tank 9 is provided with a tank drain outlet 11 .

[0012] Such as figure 1 As shown, when the electrospinning device with the electrospinning receiving device of the present invention is working, the needle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com