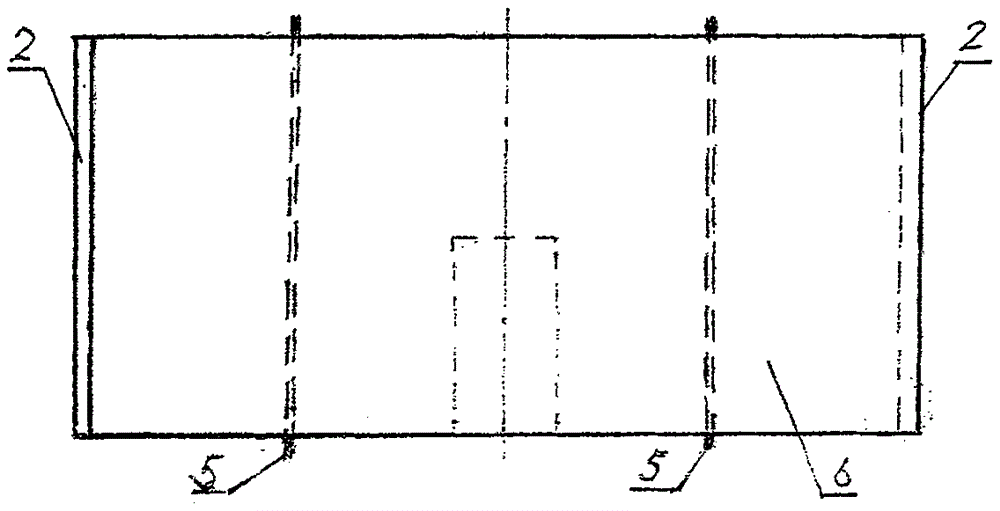

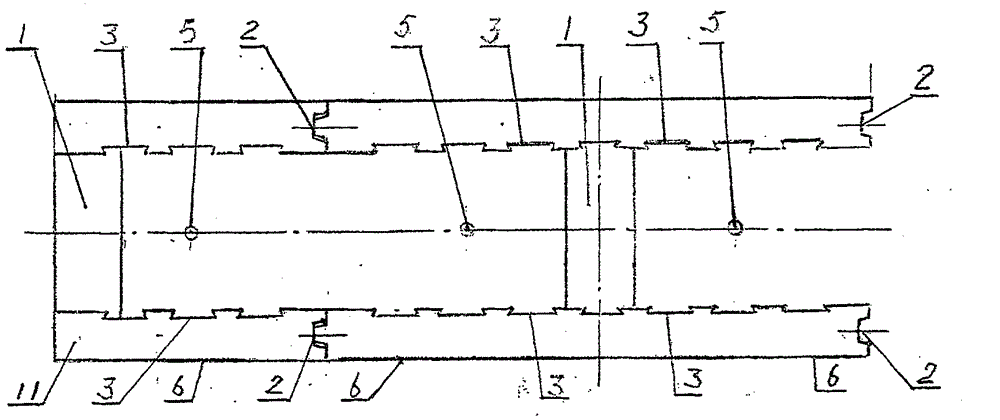

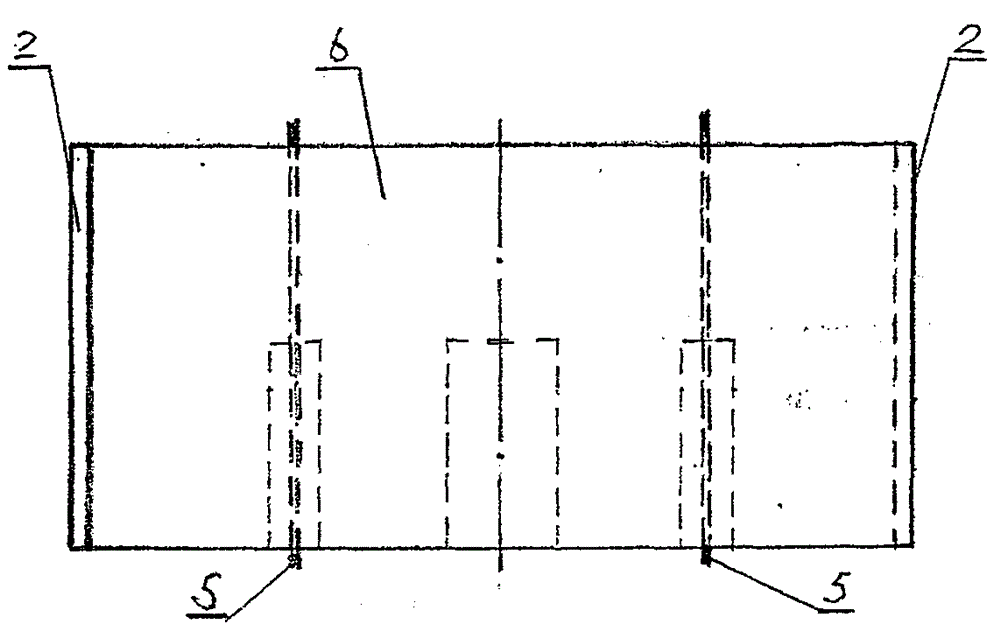

Special building block for anti-seismic energy-saving reinforced masonry of well-off building and new construction technology

A reinforced masonry and new technology, which is applied in the processing of building materials, construction, building components, etc., can solve the problems of not easy to overlap, hinder watering, and difficult to see the bottom of the hole, so as to facilitate production and construction management, Good fire resistance, corrosion resistance and durability, and the effect of improving the mechanical properties of masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will at first trial-manufacture a new block type. After the sample test is qualified, the mold of the new block type can be equipped with a batch of existing small-sized hollow block forming machines at home and abroad. The original small-block building wall "Cracking, seepage, heat" The machines that stop production in the downturn of the block factory can be mass-produced and supplied to the market with new molds. Taking advantage of the east wind of urbanization in the country, we can make great achievements; with new blocks, the new construction method conforms to According to the willingness of the workers, as long as the workers are organized to carry out short theoretical and practical training, the project can be implemented smoothly. The most difficult thing may be the design, because some of the technical solutions of the present invention are beyond the current regulations. The new block type and the new technology o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com