Self-insulating ceramsite concrete hollow block

A hollow block and concrete technology, applied in building components, buildings, building structures, etc., can solve problems such as affecting the progress of pipeline installation and interior decoration, difficulty in hanging objects on the wall, occupying the dominant construction period, etc., and achieves remarkable energy-saving effect. Good strength, excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

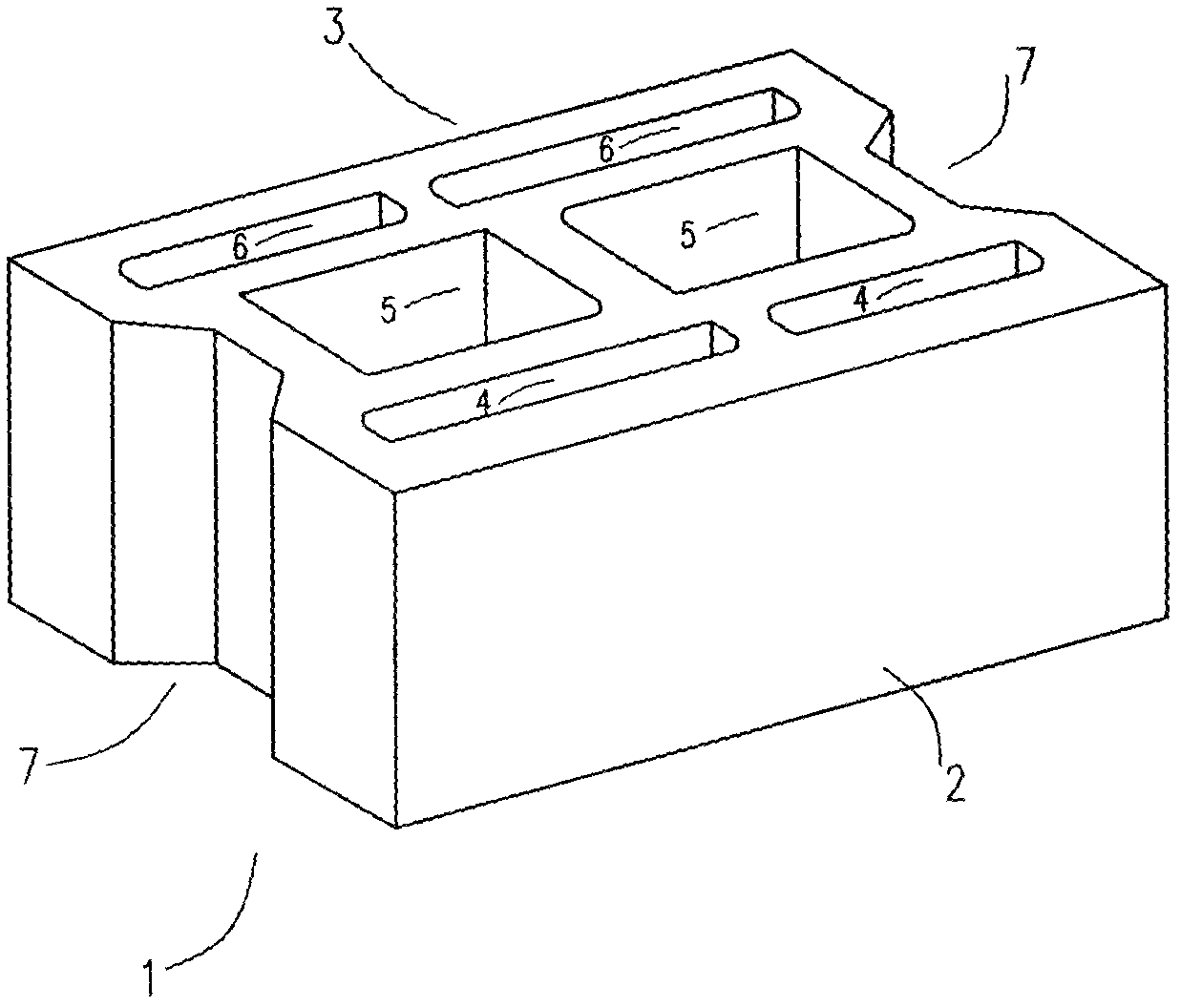

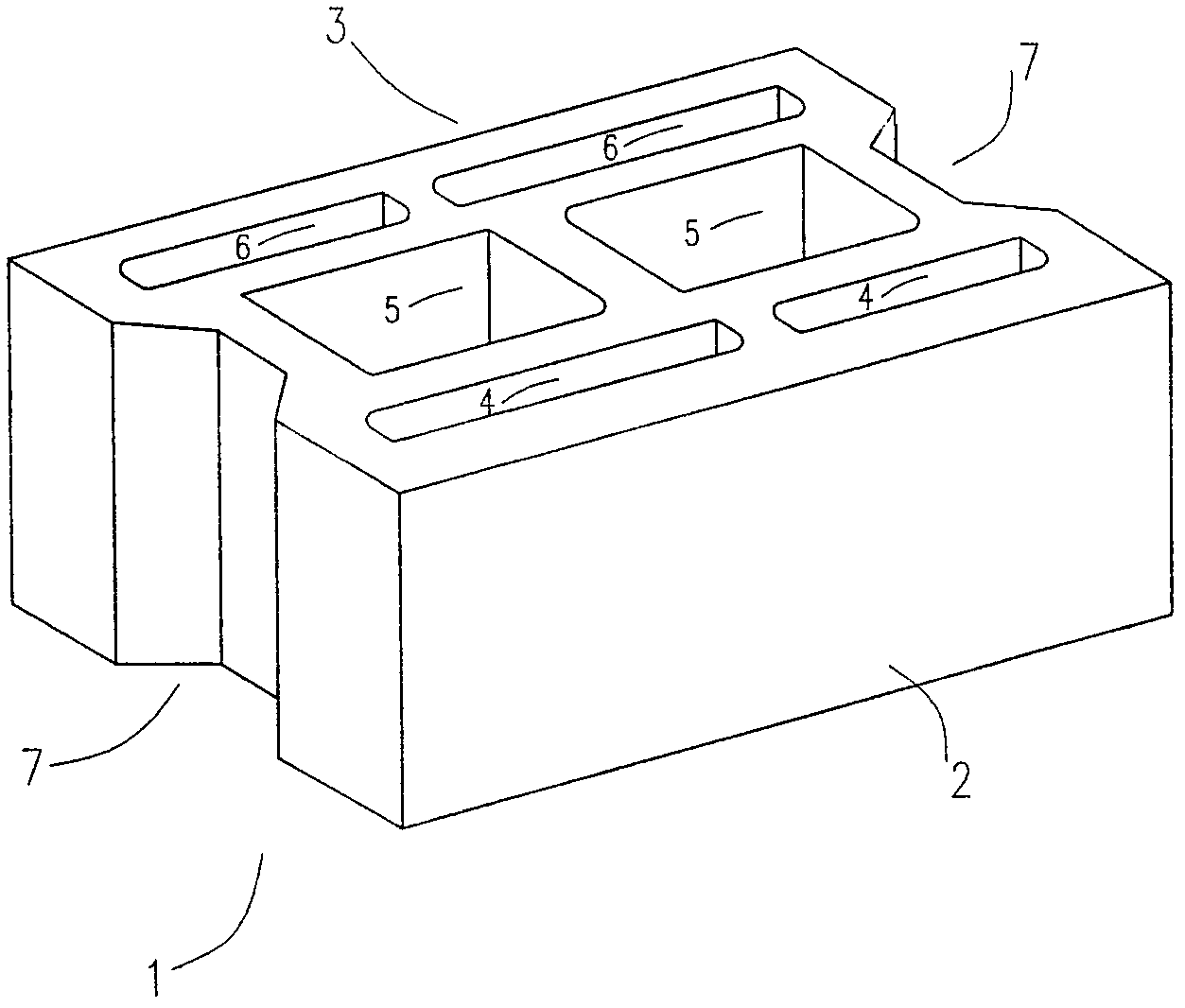

[0022] Such as figure 1 As shown, a self-insulating ceramsite concrete hollow block of the present invention is basically made of the following materials in weight percentage: ceramsite 60%, fly ash 28%, cement 12%; said ceramsite is composed of 60% The broken original ceramsite and 40% of the original ceramsite are composed; the broken original ceramsite is formed by crushing the original ceramsite through a crusher; granules, fly ash, crushed original ceramsite and cement; (2) feeding and mixing: add the above materials in proportion, and use a forced concrete mixer to fully mix with conventional water; (3) pressure vibration forming: mix the mixed materials Transport it into the block mold, and compact the material while vibrating with a compression molding machine to obtain a semi-finished block; (4) demoulding and curing: conventional method of demoulding and curing; the block structure is: a square body 1, the body There are three rows of holes between the inner end sur...

Embodiment 2

[0024] A self-insulating ceramsite concrete hollow block of the present invention is basically made of the following materials in weight percentage: ceramsite 68%, fly ash 25%, cement 7%; It is composed of ceramsite and 35% former ceramsite; the broken former ceramsite is formed by crushing former ceramsite through a crusher; Coal ash, crushed original ceramsite and cement; (2) Feeding and mixing: add the above materials in proportion, and use a forced concrete mixer to fully mix with conventional water consumption; (3) Pressure vibration forming: transport the mixed materials to the masonry In the block mould, the material is compacted while vibrating with a compression-vibration forming machine to obtain a semi-finished block; (4) demoulding and curing: conventional method of demoulding and curing; the block structure is: a square body, the inner end of the body and the There are three rows of holes between the outer end faces. The three rows of holes include the inner row o...

Embodiment 3

[0026] A self-insulating ceramsite concrete hollow block of the present invention, other schemes are the same as those in Embodiment 2, the only difference is that no straight-through notches are provided on the joint end faces on both sides of the body. The thermal insulation effect of the masonry joints is slightly worse than that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com