Protective device for electric exhaust gas recirculation (EGR) valve

A technology of EGR valve and protection device, which is applied in the direction of charging system, engine components, combustion engine, etc., can solve the problems of EGR valve failure and unavailability, valve unusability, bending deformation, etc., achieve simple structure, solve valve failure, tightness, etc. Appropriate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

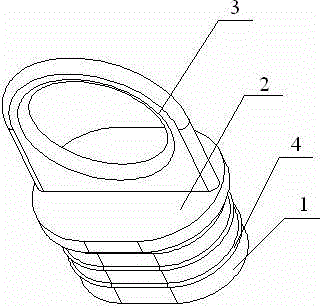

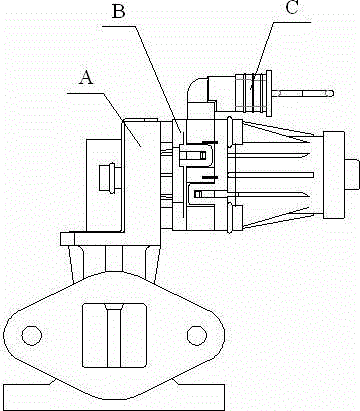

[0017] An electric EGR valve protection device, its structure is as follows figure 1 shown. Including body 1, top cover 2 and handle 3. The body 1 is matched with the shell of the linear sensor B of the electric EGR valve A, and the top cover 2 is fixedly connected to the top of the body to protect the side wall of the linear sensor shell; the handle 3 is set perpendicular to the top cover 2 and fixedly connected to the top cover 2 superior.

[0018] Several protruding reinforcing ribs 4 are arranged in parallel on the peripheral wall of the body. The reinforcing ribs protrude both toward the inner cavity of the body and outwardly to ensure the tightness of the present invention during assembly with the linear sensor.

[0019] Handle 3 is used to remove the invention from the linear sensor when the electric EGR valve is assembled. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com