Condenser steam injection vacuum system

A vacuum system and condenser technology, applied in jet pumps, machines/engines, non-displacement pumps, etc., can solve problems such as the temperature of the working fluid cannot be cooled to the design value, and achieve high reliability, simple operation, and simple system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

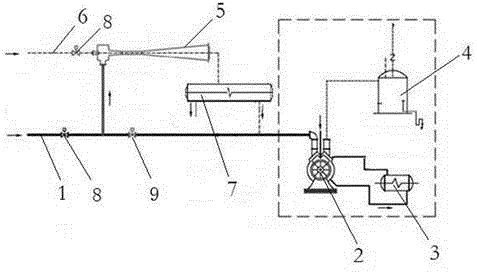

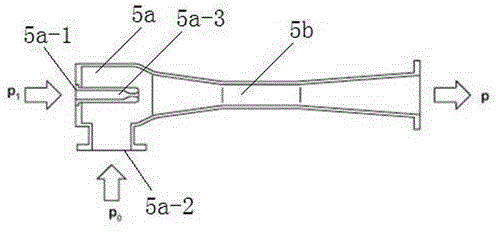

Embodiment 1

[0045] The difference between this embodiment and Embodiment 1 is that a pneumatic control valve 8 is installed at the inlet end of the condenser pipeline 1 and the power steam pipeline 6 respectively, and the condenser pipeline 1 leads to the condenser A bypass pneumatic butterfly valve 9 is installed on the rear pipe of the gas inlet 5a-2 branch. When this system is not required to work, the control room only needs to open the pneumatic butterfly valve 8 on the condenser pipeline 1 to close the power steam Pneumatic regulating valve 8 on pipeline 6, open bypass pneumatic butterfly valve 9 at the same time and get final product, this system stops working, and steam injector 5 and condenser 7 will stop working, and vacuum system will start in the working system before refitting.

Embodiment 2

[0047] The outlet pressure of the condenser 7 is designed to be 10~12kPa. Under this pressure, the vaporization temperature of the working fluid in the water ring vacuum pump 1 is about 49.5°C, which can completely solve the safety problems such as vacuum pump cavitation and rotor fracture without increasing the vacuum pump capacity. load, thereby ensuring the efficiency of the vacuum pump and maintaining the vacuum of the condenser at a high level.

Embodiment 3

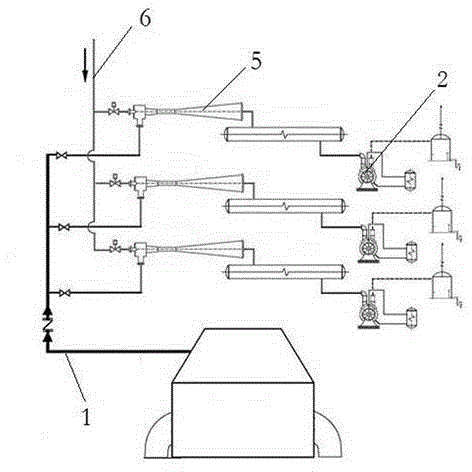

[0049] see image 3 , when the vacuum systems in the prior art are arranged in parallel to adapt to larger-scale working conditions, the steam ejectors 5 can also be connected in parallel, and each steam ejector 5 controls the number of condensers 7 connected to it respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com