Method and device for on-line verification of position sensor

A calibration method and sensor technology, applied in measuring devices, electrical devices, instruments, etc., can solve problems such as inability to calibrate the position sensor, affect the normal operation of the vehicle, and deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

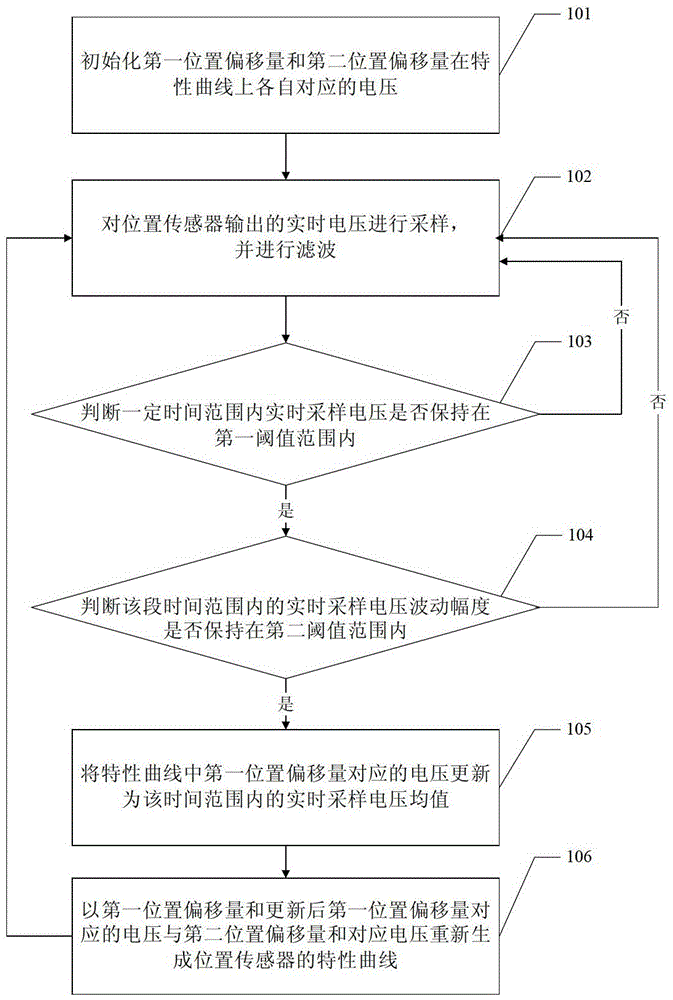

[0040] Due to assembly errors or aging problems, the characteristic curves of some position sensors deviate during the operation of the machine, and even the characteristic curves have deviations before the operation, which reduces the accuracy of the sensors. The invention provides an online calibration method for a position sensor, which checks the characteristic curve when the machine is running, see figure 1 , the method includes the following steps:

[0041] Step S101: Initializing the respective voltages corresponding to the first position offset and the second position offset on the characteristic curve;

[0042] Step S102: Sampling and filtering the real-time voltage output by the position sensor;

[0043] Step S103: judging whether the real-time sampling voltage remains within the first threshold range within a certain time range, if yes, proceed to step S104, otherwise return to step S102;

[0044] Step S104: judging whether the real-time sampling voltage fluctuati...

Embodiment 2

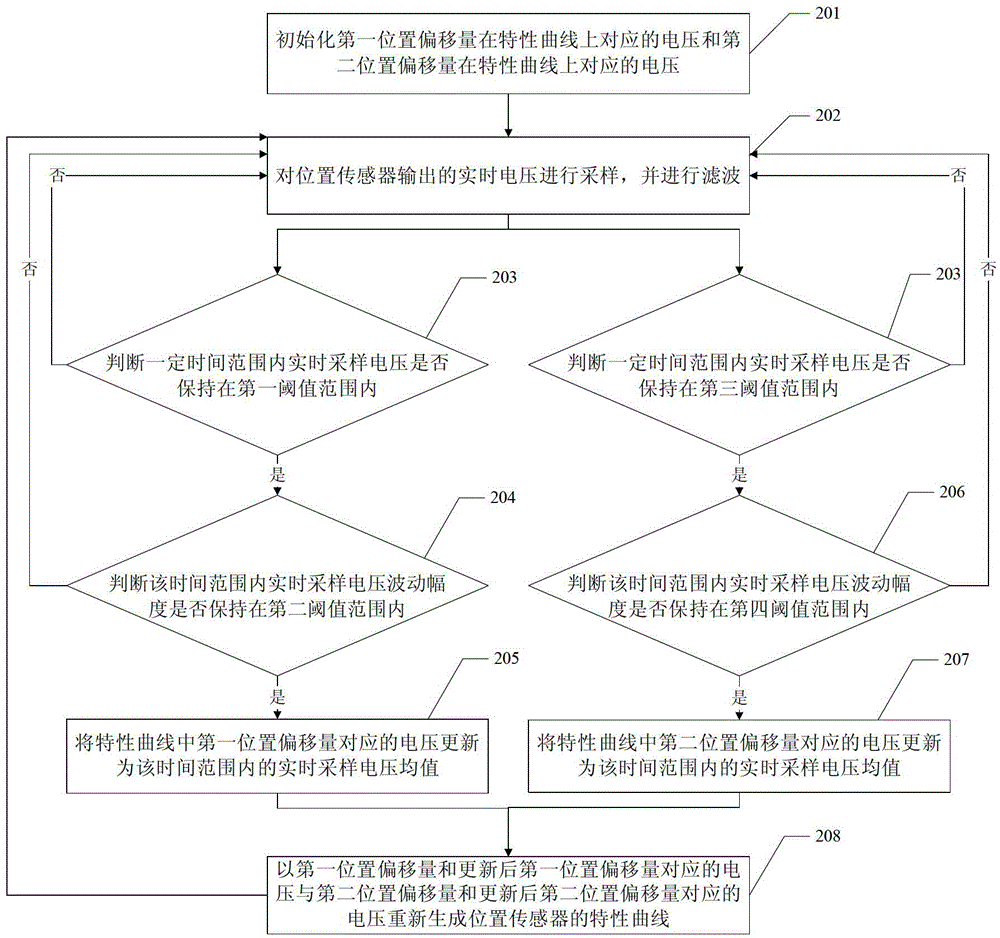

[0050] Embodiment 1 only updates the voltage corresponding to the first position offset. In practical applications, the linear curve generated by updating the voltages corresponding to the two position offsets is more accurate, so this embodiment updates the second position offset Also updated, see figure 2 ,Specific steps are as follows:

[0051] Step S201: Initialize the voltage corresponding to the first position offset on the characteristic curve and the voltage corresponding to the second position offset on the characteristic curve;

[0052] Step S202: Sampling and filtering the real-time voltage output by the position sensor;

[0053] Step S203: Determine whether the real-time sampling voltage remains within the first threshold range within a certain time range, if yes, proceed to step S204, otherwise return to step S202;

[0054] At the same time, it is judged whether the real-time sampling voltage remains within the third threshold range within the time range, if ye...

Embodiment 3

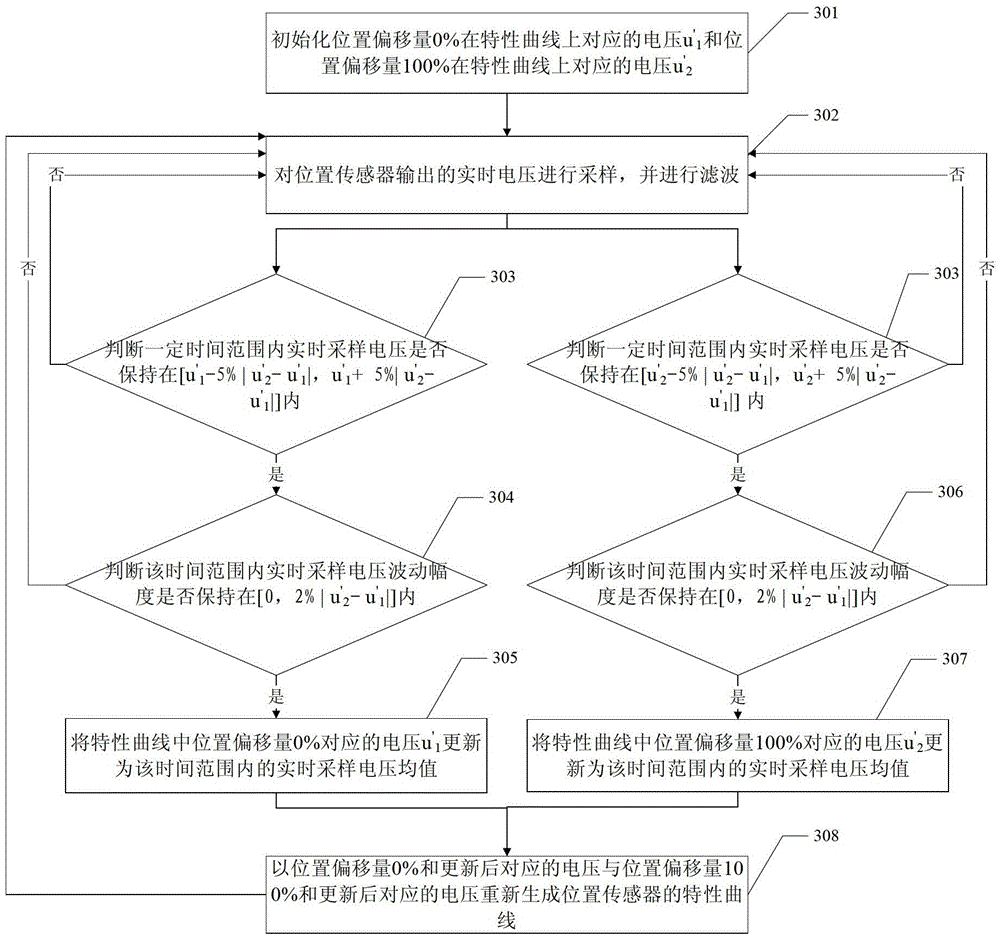

[0062] In order to further understand the present invention, this embodiment describes the online verification method of the position sensor described in the second embodiment by way of example. Since the present invention does not specifically limit the first position offset and the second position offset of the position sensor, it is preferred that the first position offset is the minimum position offset, that is, relative to the initial position offset 0%, corresponding to the voltage on the original characteristic curve as u' 1 , the second position offset is the maximum position offset, that is, it is 100% offset from the initial position, and the corresponding voltage on the original characteristic curve is u' 2 . The present invention does not specifically limit the first threshold range, the second threshold range, the third threshold range, and the fourth threshold range. In this embodiment, the preferred first threshold range is [u' 1 -x%|u' 2 -u' 1 |, u' 1 +x%|...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com