A self-calibrating relative heaving and sinking measuring system and measuring method of a ship

A measurement method and technology of measurement system, applied in measurement devices, ship safety, ships, etc., can solve problems such as inability to meet measurement and evaluation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

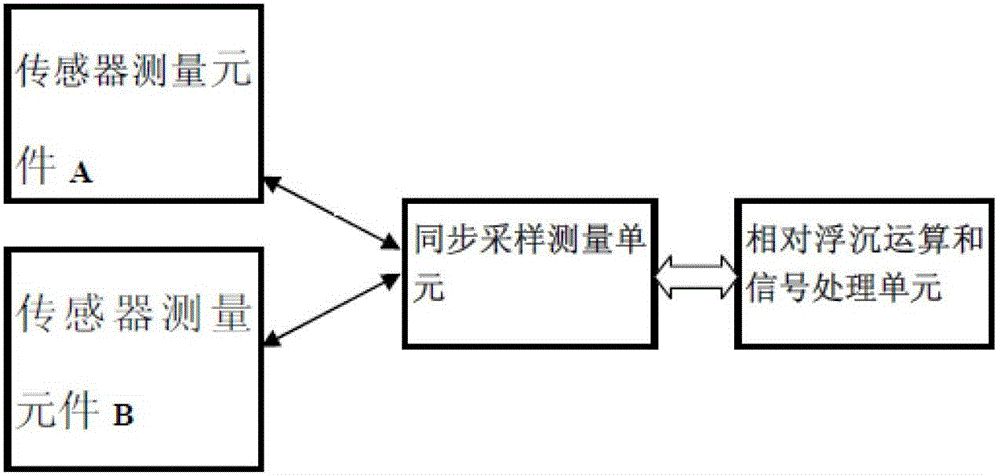

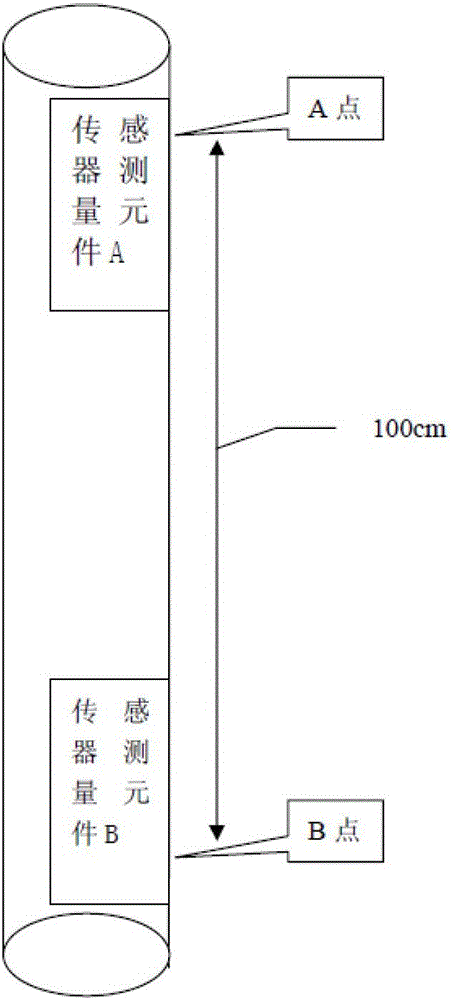

[0031] Such as figure 1 , figure 2As shown, a ship self-calibration relative ups and downs measurement system includes a ups and downs measurement sensor A, a ups and downs measurement sensor B, a synchronous measurement unit, a relative ups and downs calculation and signal processing unit; two ups and downs measurement sensors are absolute pressure sensors, and two The ups and downs measurement sensors are arranged on the inner wall of the cylindrical sleeve, fixedly installed back to back and separated by a certain distance. The distance between the two is set according to the sensor model and actual environmental conditions. In this embodiment, it is preferably 100cm. The sleeve is installed vertically on the ship. The basic measurement signals output by the two floating and sinking sensors are amplified and then input to the synchronous sampling measurement unit. The absolute pressure change and the dynamic pressure difference change of the sensor calculate the floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com