Method for testing radiation-resistant index of star sensor lens

A technology for star sensor and index testing, which is applied in the field of star sensors and can solve problems such as blank test of radiation resistance index and weak radiation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

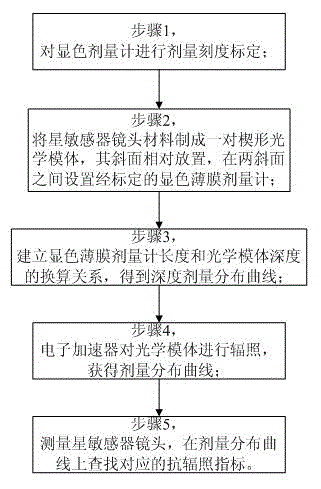

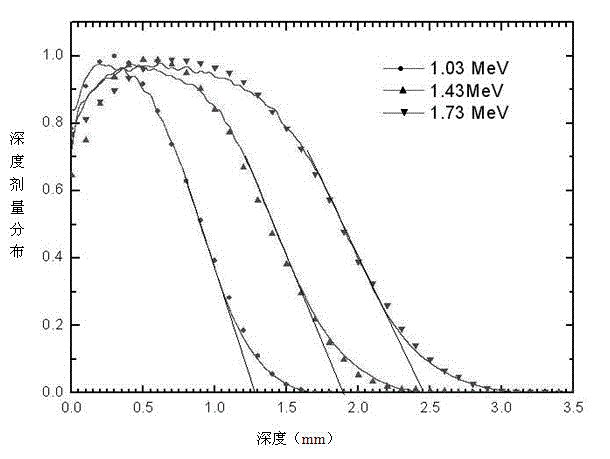

[0017] Such as figure 1 Shown, the anti-radiation index test method of a kind of star sensor lens of the present invention comprises the following steps:

[0018] Step 1: Carry out dose calibration of the chromogenic film dosimeter 2 in the standard dose field, and measure the linear relationship between the irradiation dose and the change value of the optical density by the spectrophotometer, so as to convert the optical density into the absorbed dose value.

[0019] In this embodiment, the chromogenic film dose measurement system and the EGSnrc Monte Carlo transport calculation system of the Xinjiang Institute of Physical and Chemical Technology were used.

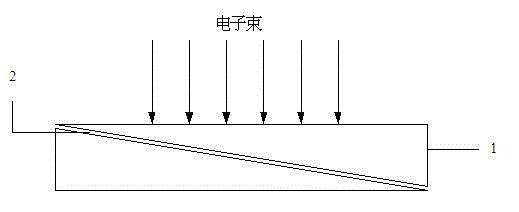

[0020] Step 2, such as figure 2 As shown, the lens material of the star sensor is made into a pair of wedge-shaped optical phantoms 1, the cross section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com