A simulation test device for preventing gas channeling in the later stage of cementing

A simulation test and anti-gas channeling technology, which is applied in the direction of material inspection products, using stable tension/pressure to test the strength of materials, etc., can solve the problem that the confining pressure cannot be applied, the action of the formation on the cement sheath cannot be simulated, and the device cannot apply confining pressure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

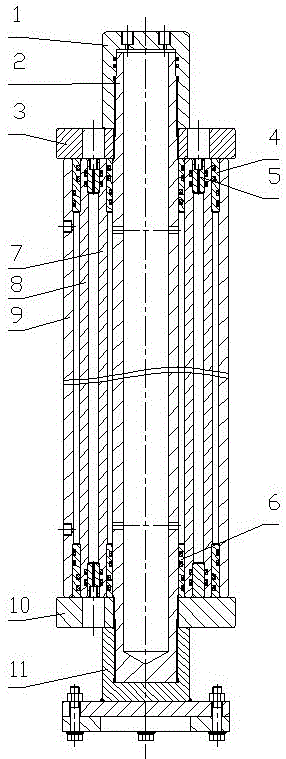

[0026] A simulation test device for preventing gas channeling in the later stage of well cementing, comprising a load-bearing tie rod 2, a cement sheath inner pipe 7, a cement sheath outer pipe 8 and an outer shell 9, a load-bearing tie rod 2, a cement sheath inner pipe 7, a cement sheath outer pipe 8 and The outer casing 9 is arranged sequentially from the inside to the outside, and the first sealed cavity is formed between the load-bearing tie rod 2 and the inner pipe 7 of the cement sheath, the inner cavity of the load-bearing tie rod communicates with the first sealed cavity, and the inner cavity of the load-bearing tie rod communicates with the first sealed cavity for injecting the medium. A connecting hole is connected; a second sealed cavity is formed between the cement sheath inner tube and the cement sheath outer tube, and the second sealed cavity is connected to the second connecting hole for injecting medium; a third seal is formed between the cement sheath outer tube...

Embodiment 2

[0037] Another preferred embodiment of the present invention simulates the cement sheath holding pressure and waiting for solidification. according to figure 1 The present invention is assembled, then block the threaded connection hole on the second sealing ring 5 of the lower part, inject cement slurry through the threaded connection hole on the second sealing ring 5 of the upper part, and fill the inner pipe 7 of the cement ring and the outer pipe 8 of the cement ring The annulus, and then hold the pressure through the threaded connection hole on the second sealing ring 5 on the upper part, to simulate the cement ring holding pressure and waiting for solidification.

Embodiment 3

[0039] Another preferred embodiment of the present invention is to simulate the pressure-holding and waiting-condensation in the cement sheath. according to figure 1 The present invention is assembled, then block the threaded connection hole on the second sealing ring 5 of the lower part, inject cement slurry through the threaded connection hole on the second sealing ring 5 of the upper part, and fill the inner pipe 7 of the cement ring and the outer pipe 8 of the cement ring The annulus is then suppressed through the threaded connection hole on the upper second sealing ring 5, and the pressure is suppressed into the inner pipe 7 of the cement sheath through the threaded connection hole of the upper plug 1, thereby simulating the pressure of the inner pipe of the cement sheath and waiting for solidification. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com