In-situ simple shear apparatus

An in-situ, shearing device technology, applied in the direction of using a stable shear force to test the strength of materials, etc., can solve the problems of laborious use of concrete shearing devices, twisting of core samples, and inability to adjust the speed of concrete core samples. , to achieve the effect of convenient and fast detection, low cost, good promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

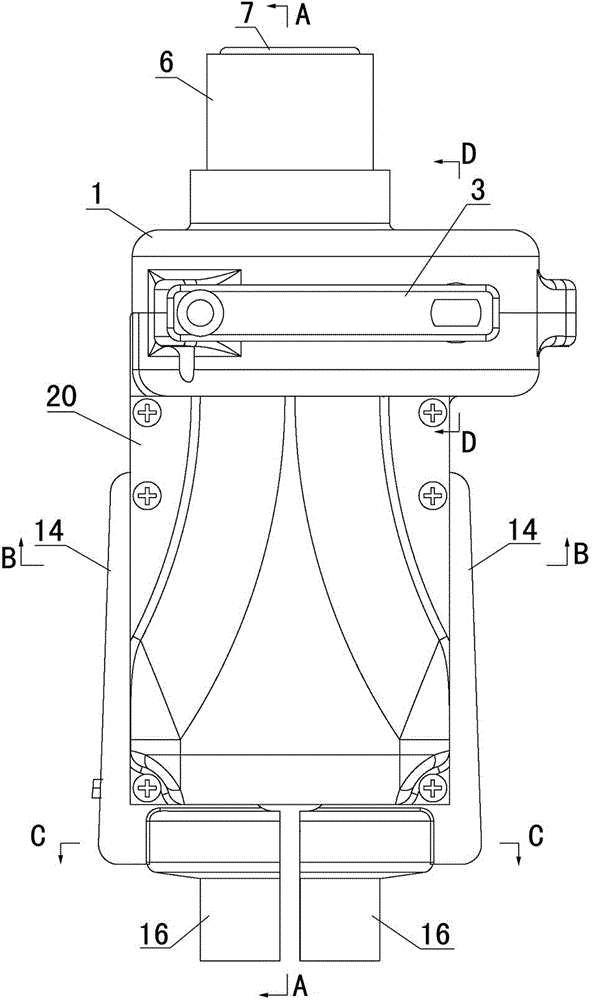

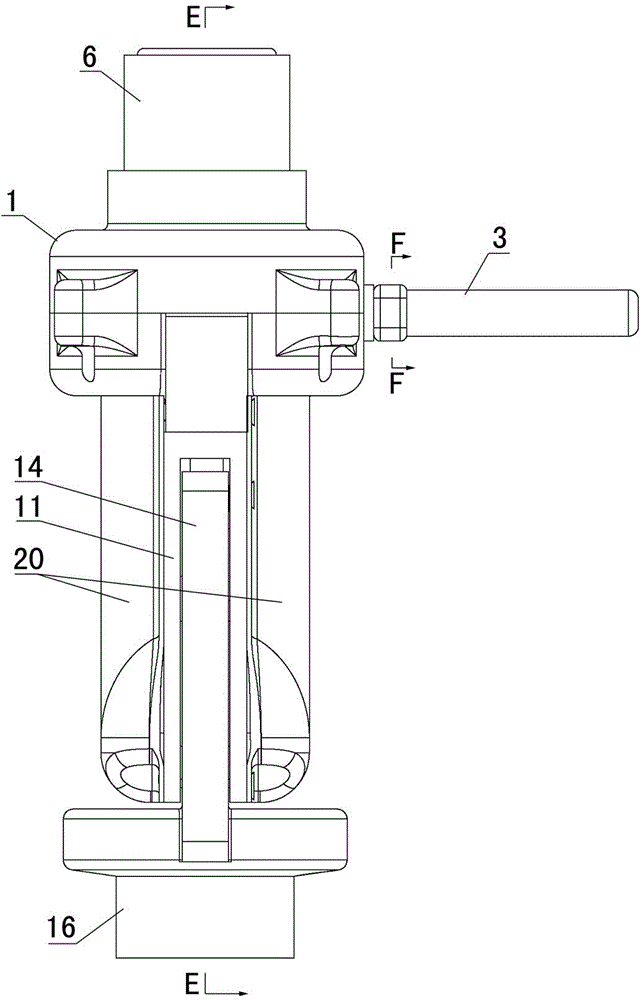

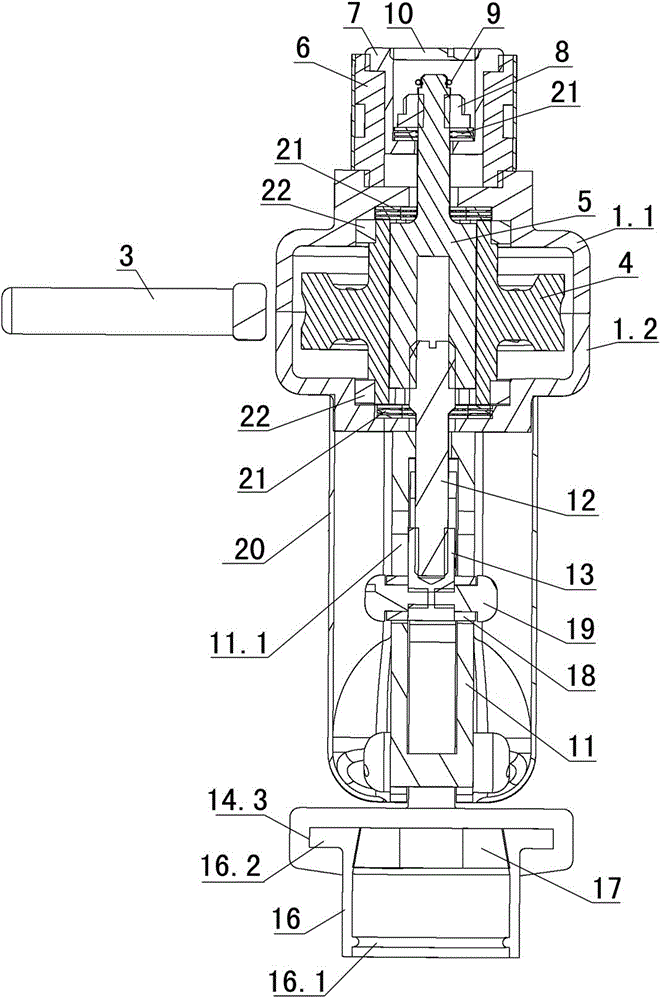

[0050] Examples see Figure 1-18 As shown, this in-situ single-shear instrument is composed of a shearing device and a data acquisition device. The shearing device includes a force application mechanism, a pressure sensing mechanism and a shearing mechanism. The data acquisition device communicates with the shearing device through a data line. The pressure sensing mechanism in the device is connected. In this embodiment, the shearing device also includes an outer shell 20 connected to the support base (see Figure 1-4 , Figure 18 ).

[0051] see Figure 1-4 , Figure 6-8 , the force applying mechanism includes a reducer housing 1, a worm 2 which is arranged in the reducer housing 1 and whose input end passes through the reducer housing to the outside of the reducer housing, and is located outside the reducer housing and is connected to the input end of the worm Drive-connected reducer handle 3 (see Figure 16 , Figure 17 ), the worm wheel 4 which is set in the reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com