Polarization rotator based on asymmetric vertical slot waveguide

A polarization rotator and slit waveguide technology, applied in the field of integrated optics, to avoid the problem of precise alignment and avoid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

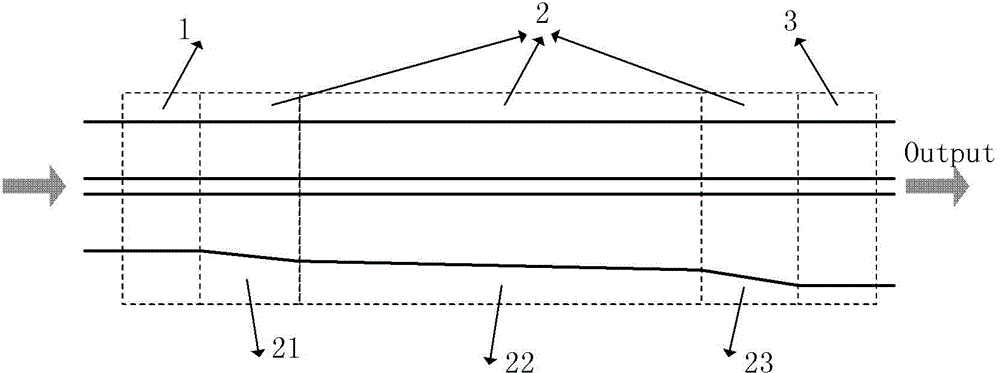

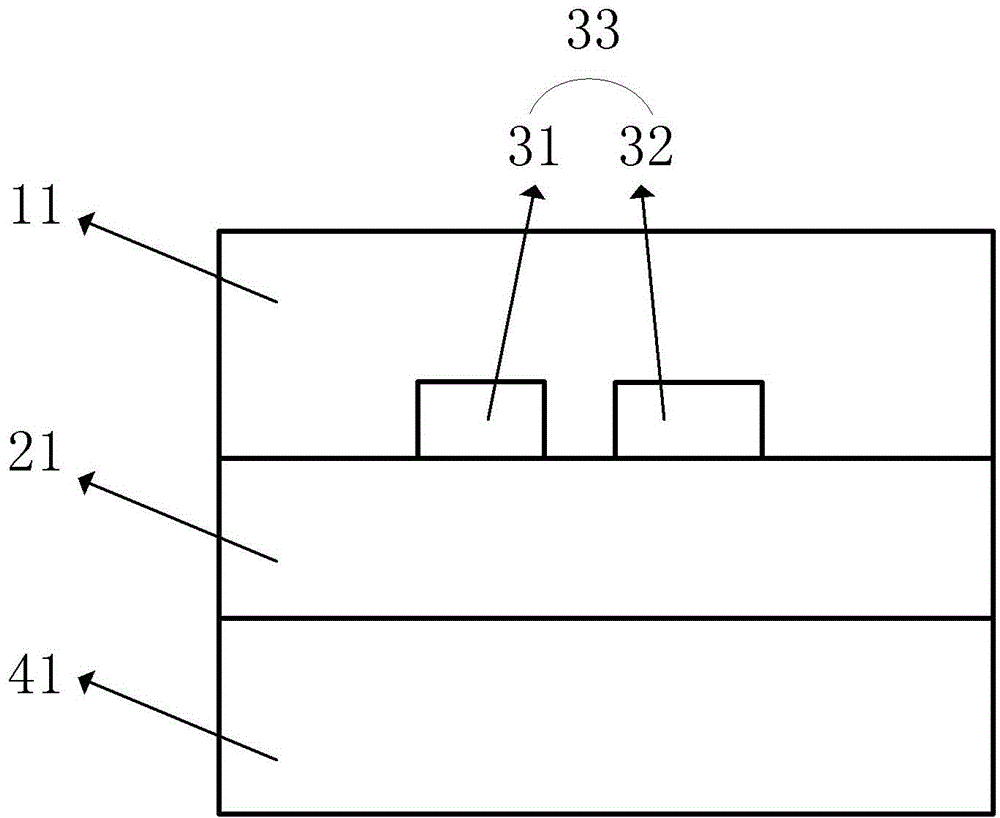

[0016] figure 1 It shows the top structural view and working process of the polarization rotator in the present invention. Such as figure 1 As shown, the polarization rotator consists of:

[0017] The waveguide 1 at the incident end is used to introduce externally incident light;

[0018] Mode conversion waveguide 2, which is used to convert the incident light of TE / TM mode into the outgoing light of TM / TE mode;

[0019] The waveguide 3 at the exit end is used to guide out the mode-converted exit light.

[0020] Wherein, the mode conversion waveguide 2 includes an input conversion waveguide 21, an intermediate conversion waveguide 22 and an output conversion waveguide 23, the initial end of the input conversion wavegu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com