Capacitive touch screen and circuit lead-out method therefor

A capacitive touch screen and touch screen technology, applied in the input/output process of data processing, electrical digital data processing, instruments, etc., can solve the problems of restricting the production efficiency and yield of FPC, complex process, and high cost of GLASS panels, which is beneficial to The effect of promoting the application, simplifying the binding process and simplifying the connection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

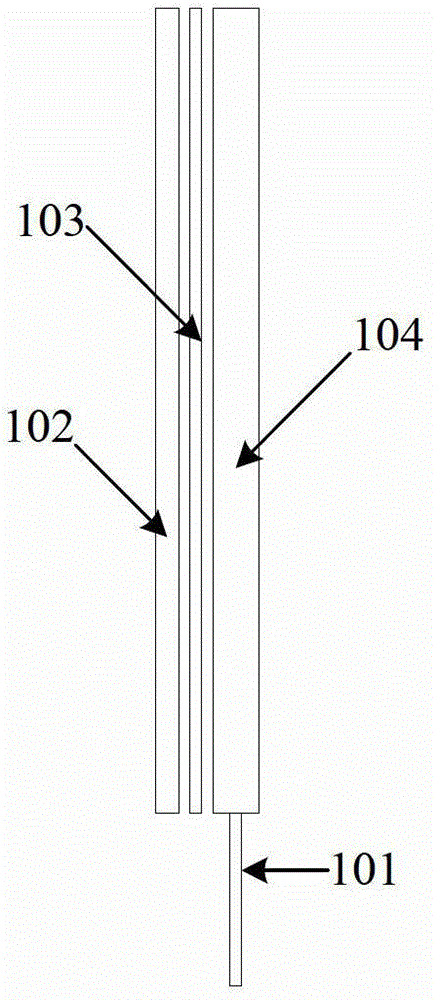

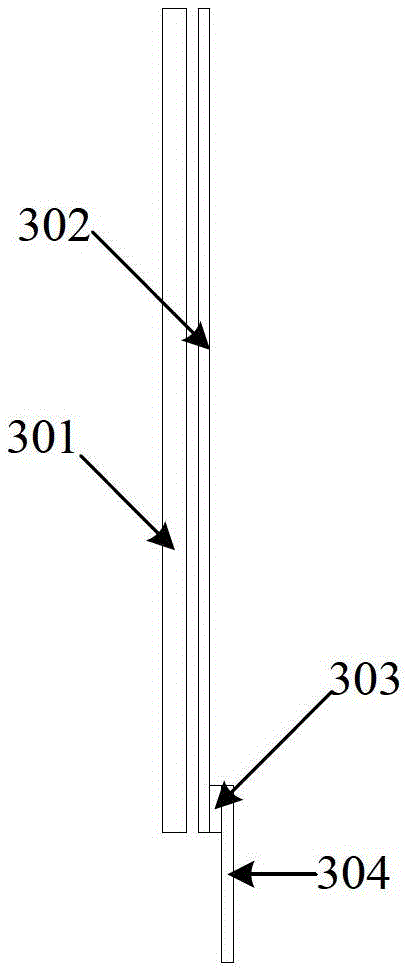

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, those of ordinary skill in the art can understand that, in each implementation manner of the present invention, many technical details are provided for readers to better understand the present application. However, even without these technical details and various changes and modifications based on the following implementation modes, the technical solution claimed in each claim of the present application can be realized.

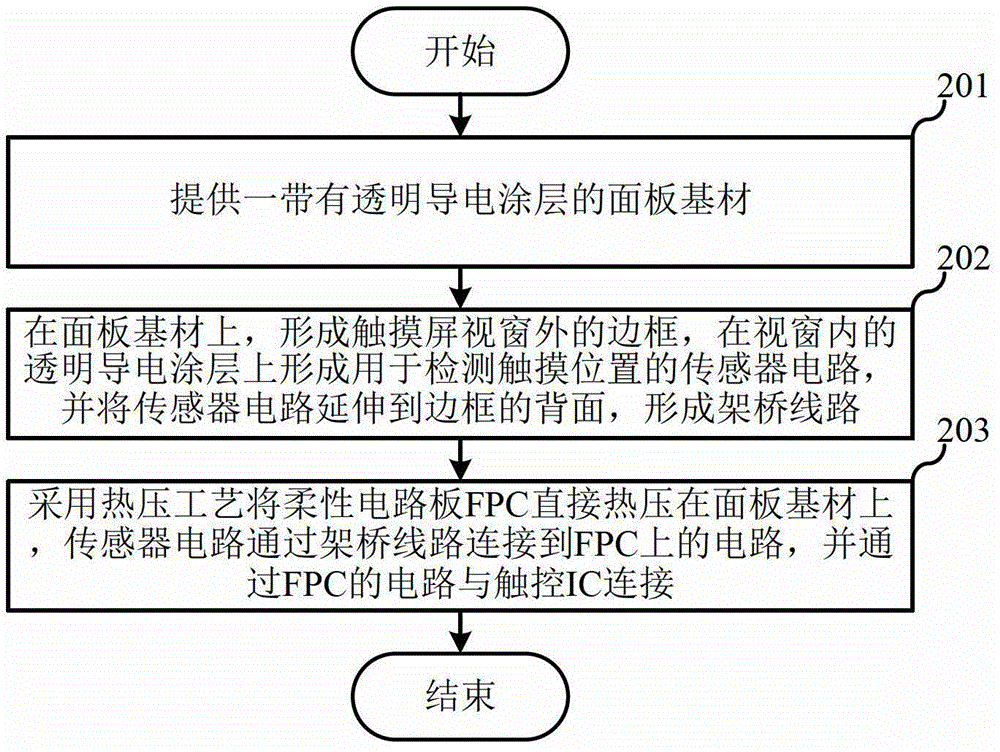

[0030] The first embodiment of the present invention relates to a method for leading out lines of a capacitive touch screen, the process of which is as follows figure 2 shown, including the following steps:

[0031] Step 201, providing a panel substrate with a transparent conductive coating. The panel substrate can be any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com