Preparation method of Si nanowire arrays

A nanowire array and reaction solution technology, applied in the field of preparation of Si nanowire arrays, can solve the problem that semiconductor materials cannot be mass-produced in industry, and achieve the effects of low equipment requirements, simple preparation, and good controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

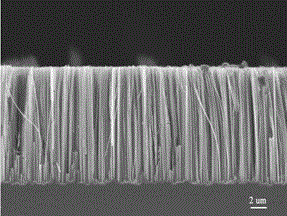

Image

Examples

Embodiment 1

[0020] 1) After cleaning the heavily doped (1 0 0) silicon wafer with a resistivity of 0.001~0.01 Ω cm by RCA method, put sulfuric acid with a mass concentration of 97% and hydrogen peroxide with a mass concentration of 30% in a volume ratio of 3:1 Soak in the mixture for 10 min. Then rinse with deionized water, and soak in 10% hydrofluoric acid buffer solution for 3 min.

[0021] 2) Mix hydrofluoric acid and silver nitrate to prepare reaction solution I, the concentration of hydrofluoric acid is 4.65 mol / L, and the concentration of silver nitrate is 0.02 mol / L; mix hydrofluoric acid and hydrogen peroxide to prepare reaction solution II, the concentration of hydrofluoric acid is 4.65 mol / L, and the concentration of hydrogen peroxide is 0.5 mol / L;

[0022] 3) Put the polished side of the silicon wafer treated in step 1) into the reaction solution I horizontally, take it out after soaking for 1 min, rinse it with deionized water, put it into the reaction solution II, react for ...

Embodiment 2

[0025] 1) After cleaning the heavily doped (1 0 0) silicon wafer with a resistivity of 0.001~0.01 Ω cm by RCA method, put sulfuric acid with a mass concentration of 97% and hydrogen peroxide with a mass concentration of 30% in a volume ratio of 3:1 Soak in the mixture for 10 min. Then the wafers were rinsed with deionized water, and soaked in 10% hydrofluoric acid buffer solution for 3 min.

[0026] 2) Mix hydrofluoric acid and silver nitrate to prepare reaction solution I, the concentration of hydrofluoric acid is 4.65 mol / L, and the concentration of silver nitrate is 0.02 mol / L; mix hydrofluoric acid and hydrogen peroxide to prepare reaction solution II, the concentration of hydrofluoric acid is 4.65 mol / L, and the concentration of hydrogen peroxide is 0.5 mol / L;

[0027] 3) Put the polished side of the silicon wafer treated in step 1) into the reaction solution I horizontally, soak for 1 min, take it out, rinse it with deionized water, put it into the reaction solution II,...

Embodiment 3

[0030] 1) After cleaning the heavily doped (1 0 0) silicon wafer with a resistivity of 0.001~0.01 Ω cm by RCA method, put sulfuric acid with a mass concentration of 97% and hydrogen peroxide with a mass concentration of 30% in a volume ratio of 3:1 Soak in the mixture for 10 min. Then rinse with deionized water, and soak in 10% hydrofluoric acid buffer solution for 3 min.

[0031] 2) Mix hydrofluoric acid and silver nitrate to prepare reaction solution I, the concentration of hydrofluoric acid is 4.65 mol / L, and the concentration of silver nitrate is 0.02 mol / L; mix hydrofluoric acid and hydrogen peroxide to prepare reaction solution II, the concentration of hydrofluoric acid is 4.65 mol / L, and the concentration of hydrogen peroxide is 0.5 mol / L;

[0032] 3) Put the polished side of the silicon wafer treated in step 1) into the reaction solution I horizontally, take it out after soaking for 1 min, rinse it with deionized water, put it into the reaction solution II, react for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap