A 12/4 pole single winding bearingless switched reluctance motor and its control method

A switched reluctance motor and bearingless technology, which is applied in the direction of AC motor control, control system, synchronous machine, etc., can solve the problems of bearingless motor suspension instability, complex control algorithm, and affecting the real-time control effect of suspension force, etc., to achieve the concept Novel, simplified control algorithm, ingeniously designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

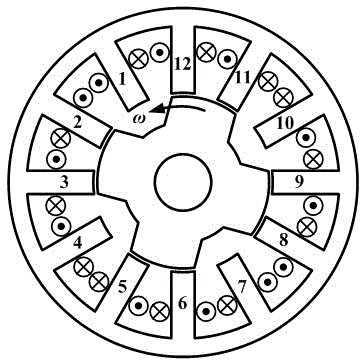

[0016] A 12 / 4 pole single winding bearingless switched reluctance motor, its structure is as follows figure 1 As shown, it consists of a stator with 12 tooth poles and a rotor with 4 tooth poles. Each pole of the stator is independently wound with a set of field windings. There is no winding on the rotor. The rotor of a 12 / 4-pole single-winding bearingless switched reluctance motor The teeth are 30° wider than the stator teeth.

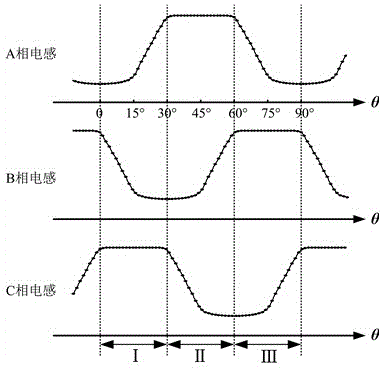

[0017] The control method of the 12 / 4-pole single-winding bearingless switched reluctance motor is described as follows:

[0018] 1. The controller and current conduction mode of the stator winding: 12 sets of windings are independently controlled, and the current of each set of windings is unidirectionally conducted. The asymmetrical half-bridge circuit is selected as the circuit topology of the main winding power converter. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com