Tool turret for machining workpieces and machining system with such tool turret

A technology for tool turret and workpiece processing, which is applied in metal processing machinery parts, tool holders, manufacturing tools, etc., can solve the problems of no longer being able to replace tools, different expansion characteristics, and tool turret clamping, etc., to avoid thermal stress. , high cutting speed, improved productivity and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

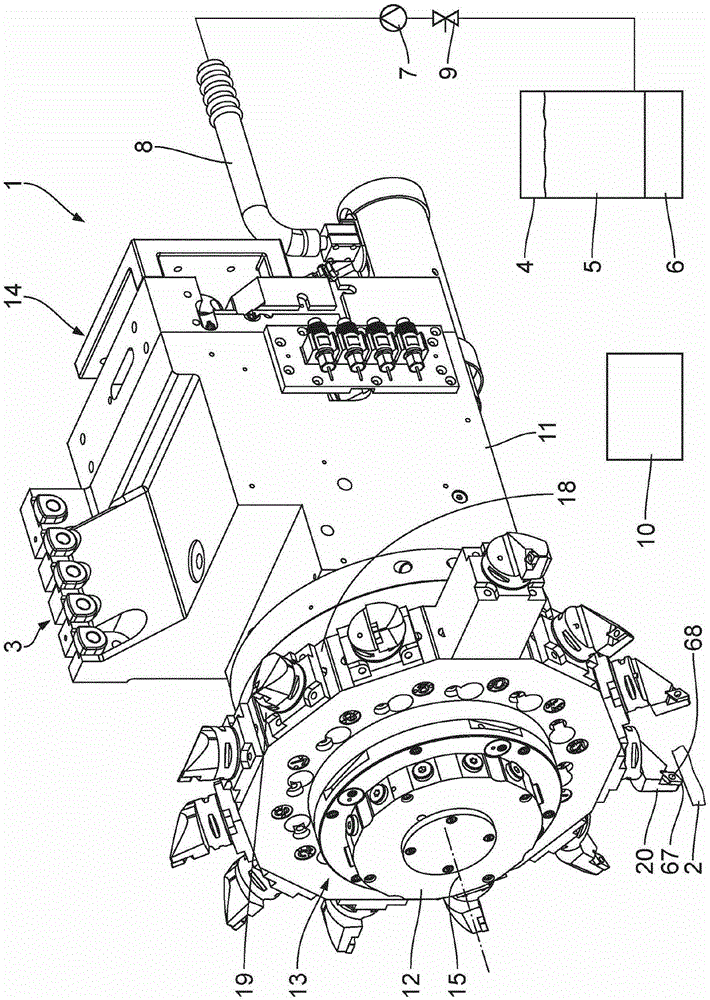

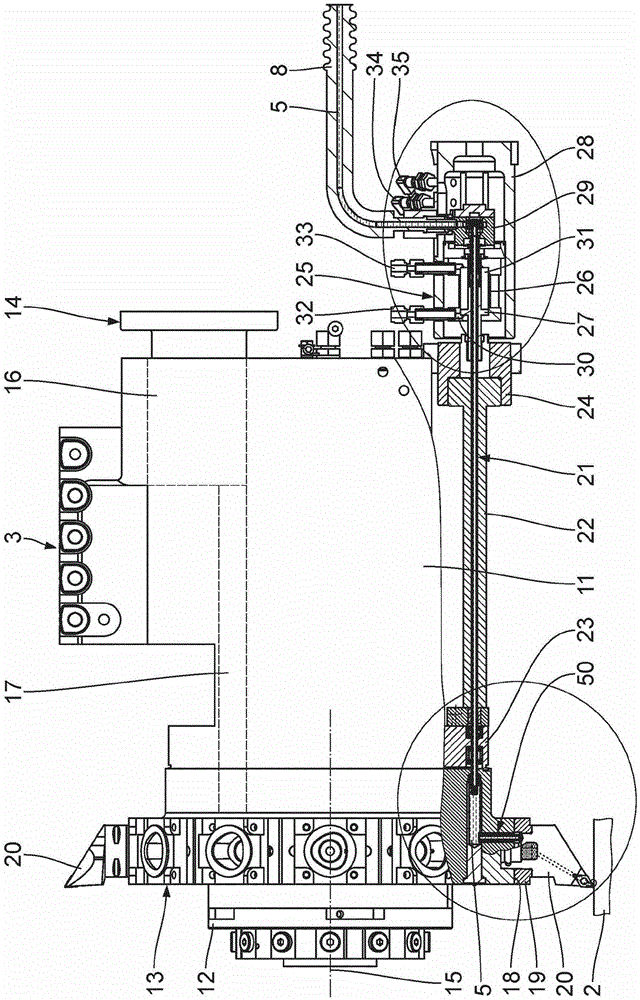

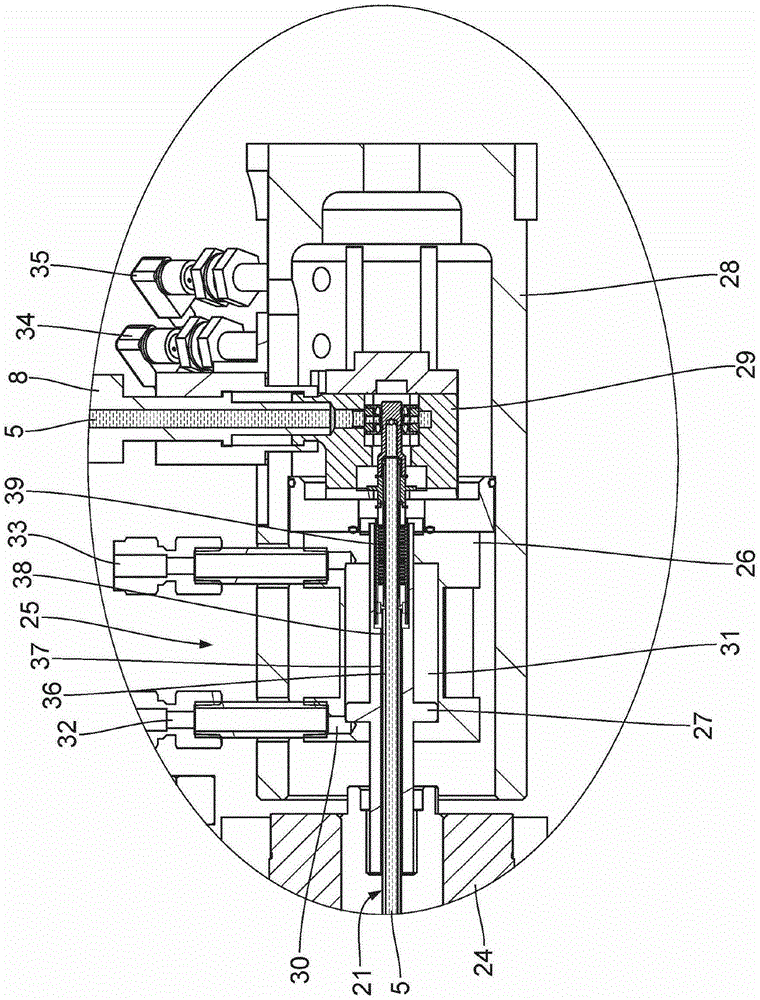

[0032] Refer below Figures 1 to 6 A first embodiment of the present invention will be described. The machine tool, not shown in detail, has a processing system 1 for cutting metal workpieces 2, which processing system includes a tool turret 3, a store 4 for providing thermal insulation of a cryogenic cooling medium 5, a cryogenic cooling medium 5 for cooling Cooler device 6 for medium 5 , delivery pump 7 , supply line 8 with associated shut-off valve 9 and control device 10 . The supply line 8 is connected to the accumulator 4 and the tool turret 3 and is thermally insulated. The tool turret 3 , the cooler device 6 , the delivery pump 7 and the shut-off valve 9 can be controlled by means of a control device 10 . Machine tool configurations other than the machining system 1 are conventional and known.

[0033] The tool turret 3 has a housing 11 in which a fixed central shaft 12 is mounted. The central shaft 12 protrudes from the housing 11 at the end and serves to support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com