foam dispenser

An ejector and foam technology, applied in the direction of ejection device, liquid ejection device, closing, etc., can solve the problems of limited liquid passage size, increased manufacturing cost, large ejection head, etc., to prevent bad situations and reduce the use of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

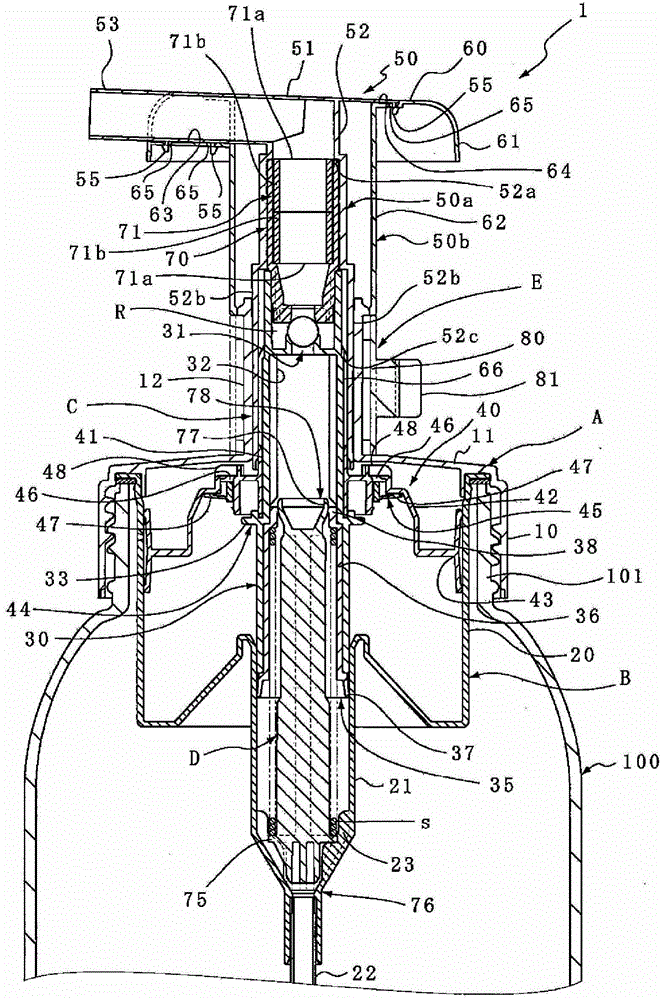

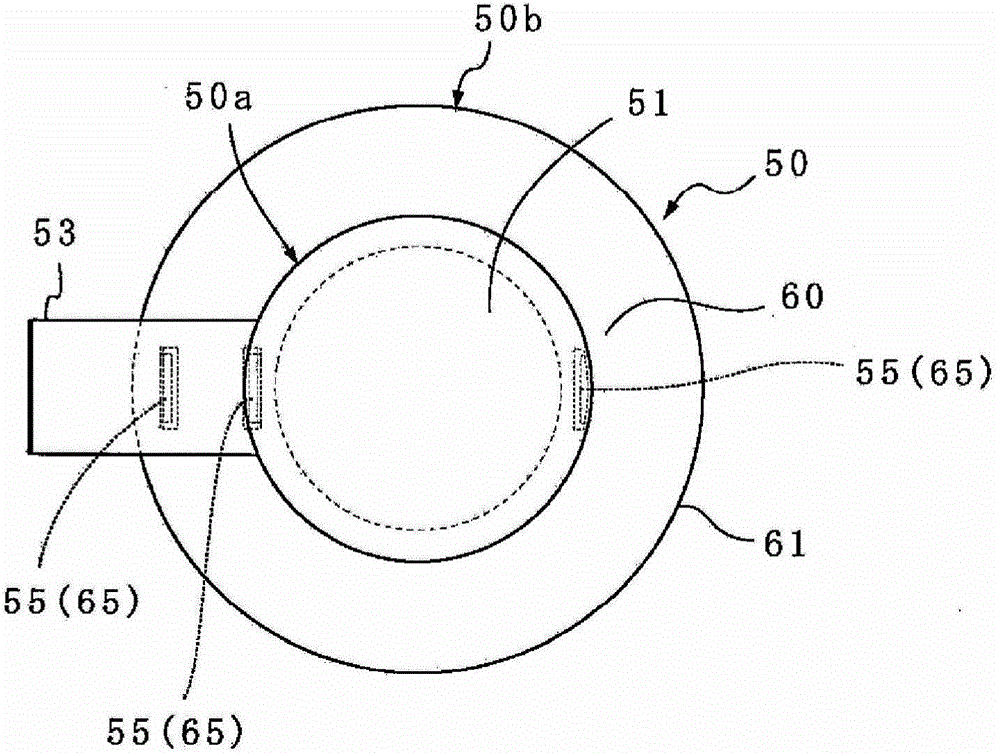

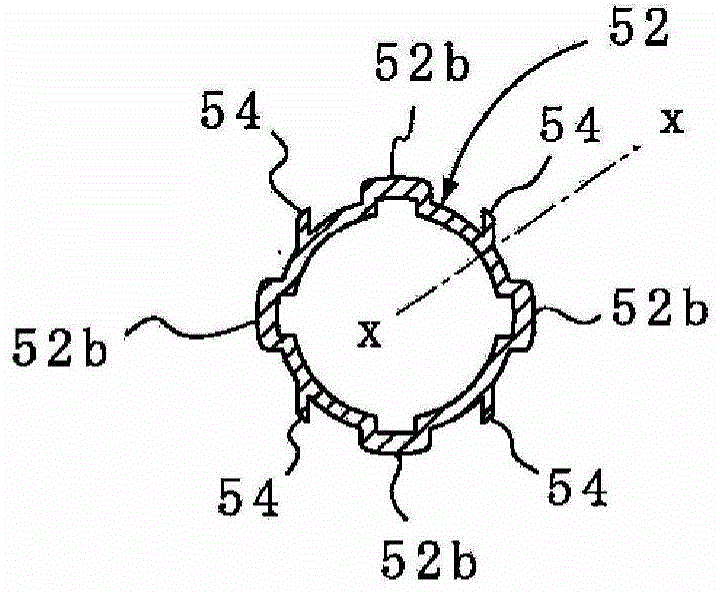

[0029] figure 1 as well as figure 2 It is a figure which shows an example of the foam dispenser 1, and the foam dispenser 1 is provided with the mounting cap A, the cylinder member B, the operation member C, the poppet valve body D, and the spacer E.

[0030] The mounting cap A is a component for fixing the foam sprayer 1 to the container body 100, and the mounting cap A is extended from the upper end edge of the peripheral wall 10 of the outer periphery of the mouth and neck portion 101 of the container body 100, and is set at the center. The top wall 11 of the window hole through which the operating member C penetrates, and a guide cylinder 12 is provided standing upward from the periphery of the window hole.

[0031] In the cylinder member B, a small-diameter liquid cylinder 21 is concentrically extended below a large-diameter air cylinder 20 whose upper end is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com