Device and method for moisture recovery and gypsum rain control in wet desulphurization flue gas of thermal power plant

A technology for wet desulfurization and thermal power plant is applied in the field of moisture recovery and gypsum rain treatment devices in the wet desulfurization flue gas of thermal power plants. degree, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

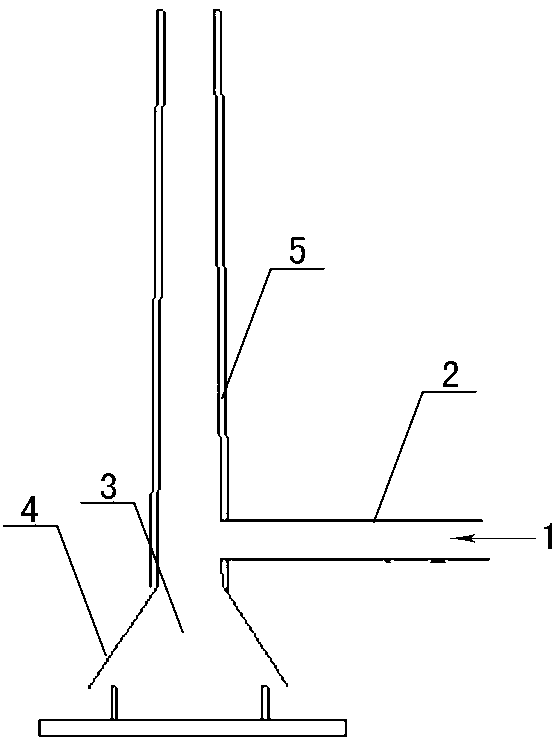

[0026] See attached figure 1 , the lower part of the chimney inner cylinder 5 is short cylindrical, the upper part is high cylindrical, and the short cylindrical and high cylindrical are connected by a conical form. The hot flue gas 1 enters from the lower part of the high cylinder through the flue 2; a plurality of air inlets 3 are arranged on the wall of the short cylinder part of the chimney, and the air enters the chimney from the air inlet 3, and a conical air inlet 3 is installed above the air inlet 3 Surrounding eaves 4, the surrounding eaves 4 are the part extending downwards from the conical surface of the conical part of the chimney, the size of the air inlet 3 is adjustable, and the flow rate of the incoming air is adjusted by adjusting the size of the air inlet 3. Air is sucked into the flue and / or chimney through the self-extraction force of the flue and / or chimney, the air is mixed with the flue gas, the temperature of the flue gas is lowered, the water vapor in ...

Embodiment 2

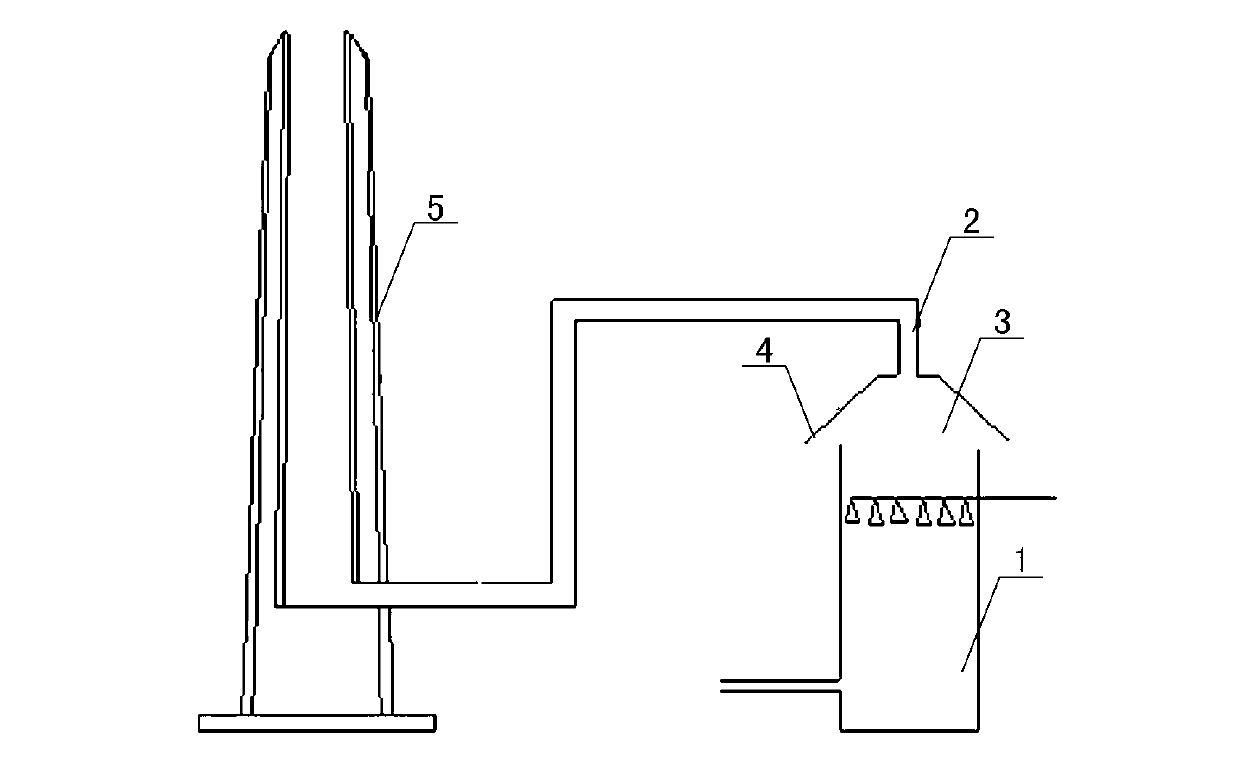

[0028] See attached figure 2 , the flue 2 includes a wet desulfurization absorption tower 1, the tower top is conical, and the tower wall is vertical; a vertical flue is installed on the conical tower top, and the diameter of the vertical flue is smaller than that of the wet desulfurization absorption The diameter of the tower makes the flue gas flow out from the top of the wet desulfurization absorption tower. A plurality of air inlets 3 are arranged on the wall surface of the upper part of the vertical tower wall, and the air enters the wet desulfurization absorption tower 1 from the air inlets 3, and a conical eaves 4 are installed above the air inlets 3, and the enclosure The eaves 4 are the part extending downward from the conical surface of the conical tower top. The size of the air inlet 3 is adjustable, and the flow rate of the incoming air is adjusted by adjusting the size of the air inlet 3 . Air is sucked into the flue and / or chimney through the self-extraction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com