Rear suspension system of mining dump vehicle

A mining dump truck, rear suspension technology, applied in the direction of interconnection system, suspension, elastic suspension, etc., can solve the problems of high failure rate, high cost and low capacity of 4 × 2 mining dump trucks, and improve the Bearing capacity, highlighting substantive features, and reducing the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand and implement, below in conjunction with accompanying drawing, specific embodiment is given to describe the present invention in detail; The given embodiment is only used to explain the present invention, is not intended to limit the scope of the present invention

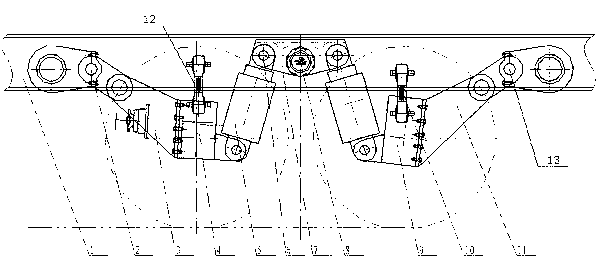

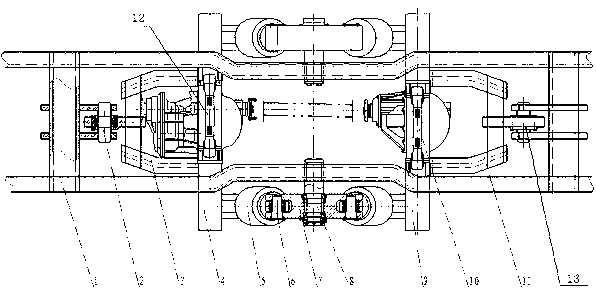

[0013] Embodiment 1, see Fig. 1, figure 2 According to the design requirements, the front bracket 3 is connected with the frame 1 through the first pin shaft 2, the middle bridge 4 is rigidly connected with the front bracket 3, and the middle bridge 4 is connected with the frame 1 through the second thrust rod 12, so as to ensure that the middle bridge 4 Can only rotate around the first pin shaft 2; the rear bracket 11 is connected to the frame 1 through the third pin shaft 13, the rear axle 9 is rigidly connected to the rear bracket 11, and the rear axle 9 is connected to the frame 1 through the first thrust rod 10 , so as to ensure that the rear axle 9 can only rotate around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com