Crude tobacco bale automatic basket filling system

A cigarette pack, automatic technology, applied in the directions of packaging, transportation and packaging, destacking of objects, etc., can solve the problems of shredding raw tobacco leaves, consuming a lot of manpower, loss of raw cigarettes, etc., so as to reduce the loss of shredding and save labor. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The preferred embodiment of the automatic basket loading system for raw cigarette packs of the present invention is:

[0024] It includes a cigarette pack conveying part and an automatic basket feeding part, a cigarette pack shaping basket part is provided between the cigarette pack conveying part and the automatic basket feeding part, and a cigarette basket conveying part is arranged at the lower part of the cigarette pack shaping and basket loading part, The middle part of the cigarette pack conveying part is provided with an emergency pack unloading channel.

[0025] The cigarette bale conveying part includes a slope conveyor belt, a buffer roller table, and a chain conveyor belt connected in sequence. A buffering mechanism is provided between the buffer roller table and the chain conveyor belt, and a platform is provided at the lower part of the buffer roller table.

[0026] The buffer roller table is a smooth roller conveying roller table, and the buffer bag blocki...

specific Embodiment

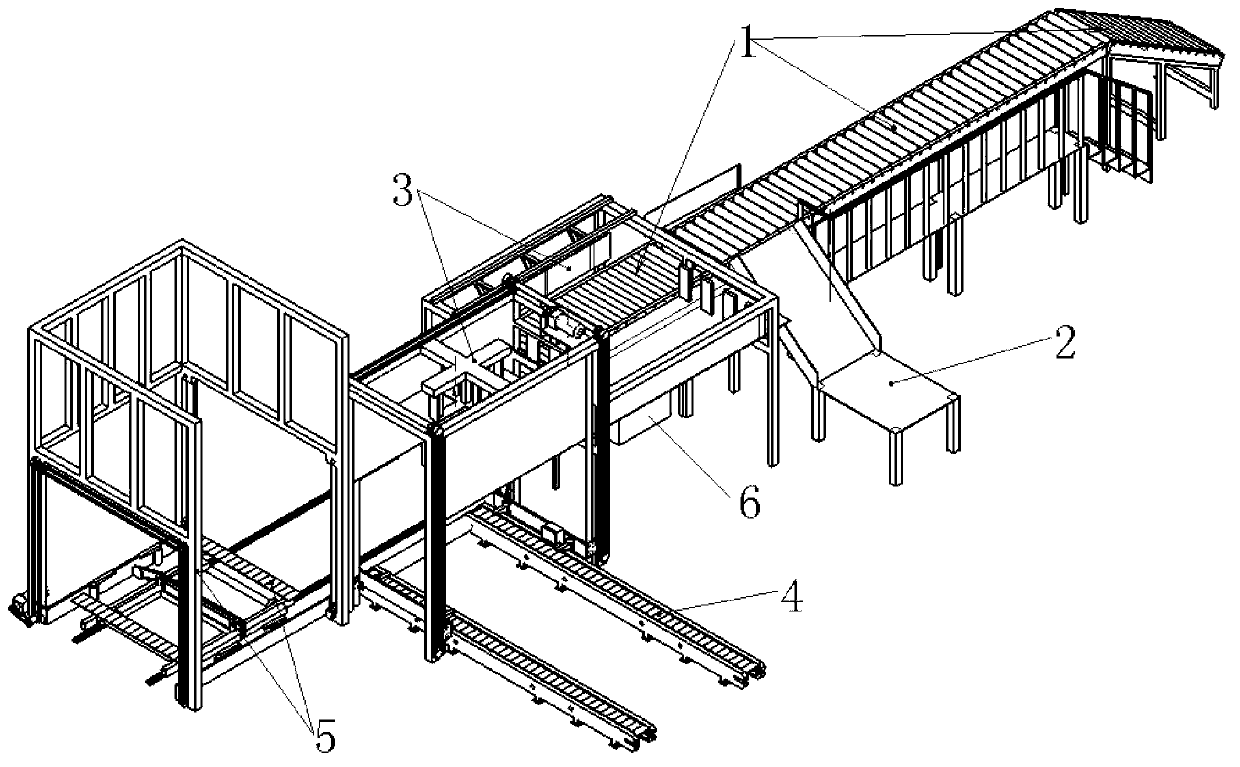

[0033] Such as figure 1 As shown, it includes the cigarette pack conveying part, the emergency pack unloading channel, the cigarette pack shaping and loading part, the cigarette basket conveying part, the automatic basket feeding part, the electric control cabinet, etc.

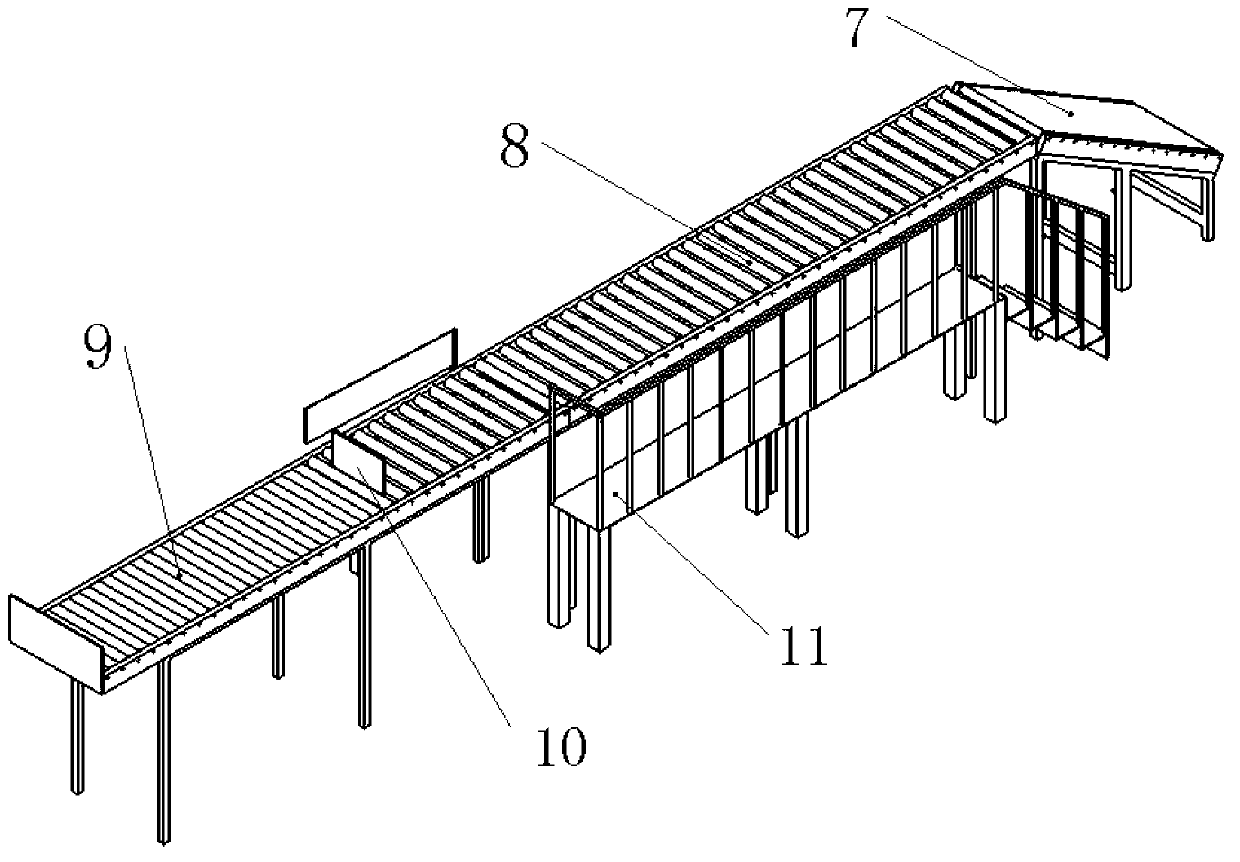

[0034] Such as figure 2 As shown, the cigarette bale conveying part includes a slope conveyor belt, a buffer roller table, a chain plate conveyor belt, a buffer blocking bag mechanism, a platform, etc., the slope conveyor belt is ordinary straw belt transmission, and the buffer roller table is a smooth roller transmission roller table. The buffer and bag blocking mechanism is composed of a cylinder drive device and a shift fork baffle, and the chain-plate conveyor belt is an ordinary chain-plate conveyor belt.

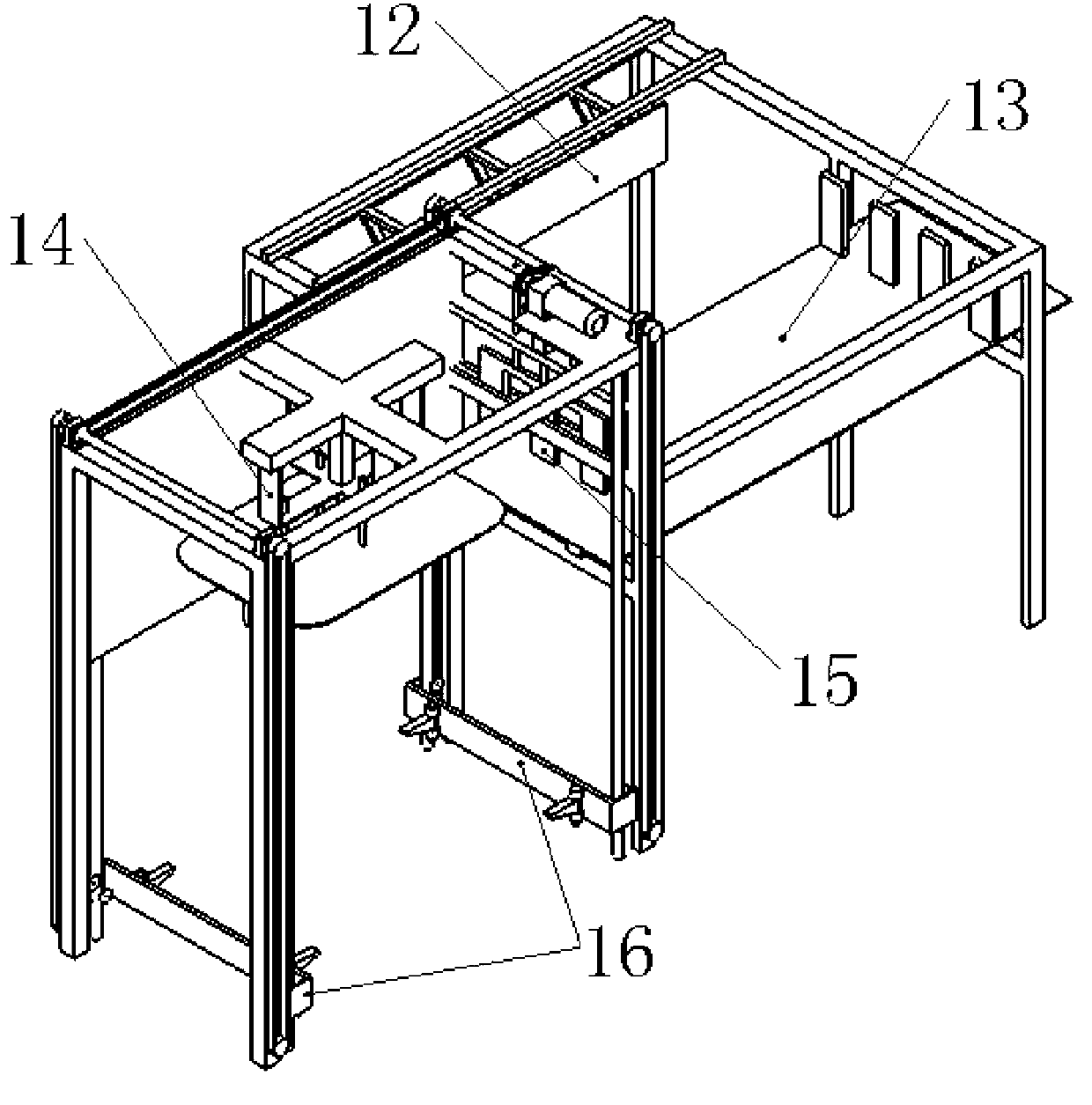

[0035] Such as image 3 As shown, the cigarette pack shaping and loading basket part includes a cigarette pack shaping mechanism, a cigarette packing basket mechanism, a pack pressing mechanism, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com