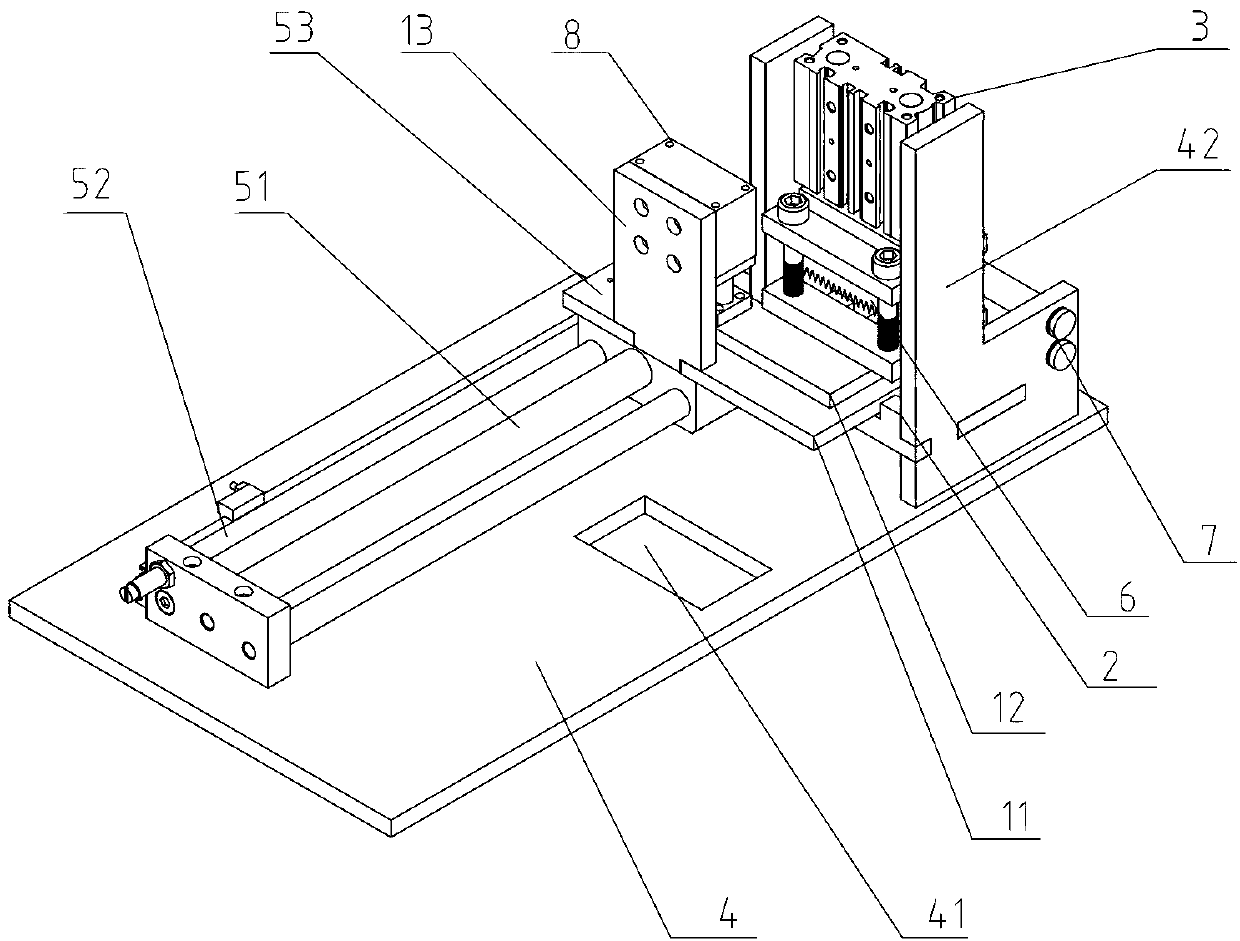

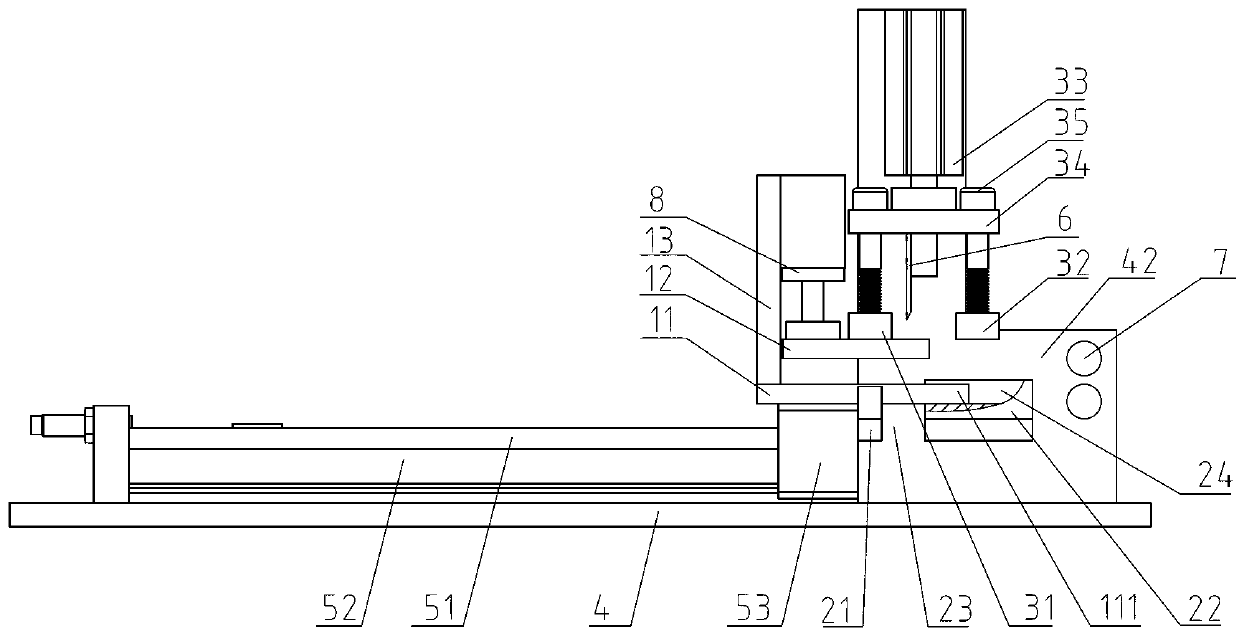

Film feeding mechanism of storage battery wrapped cell feeding slot machine

A slotting machine and storage battery technology, applied in secondary battery manufacturing, delivery of objects, transportation and packaging, etc., can solve problems affecting work efficiency, lack of tools, extreme group pollution, etc., to achieve film cutting, simple structure and principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides a film feeding mechanism of a storage battery sheet slotting machine, which includes a film supporting plate, a film taking device and a film cutting knife. A film taking device is arranged on one side of the film supporting plate. The upper clamping plate and the lower clamping plate are close to each other to clamp the first driving device for the film, and the second driving device for driving the upper clamping plate and the lower clamping plate to move laterally and pull out the film. The film support plate includes a front film support plate and a rear film support plate. A film cutting opening is formed between the plate and the rear support film plate, and a film cutting knife is arranged directly above the film cutting opening. The film feeding mechanism also includes a film fixing device, which fixes the film on the film support plate when cutting the film. During the working process, the film taking device takes the film from the film su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com