Organic silicon modified acrylic resin primer of plastic articles

A technology of acrylic resin and silicone, which is applied in the direction of coating, etc., can solve the problems of weak adhesion, plastic primer cannot be applied to plastic parts of different materials, and poor cooking resistance, so as to improve work efficiency and good cooking resistance Sexuality and resistance to cold and heat, reducing waste and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

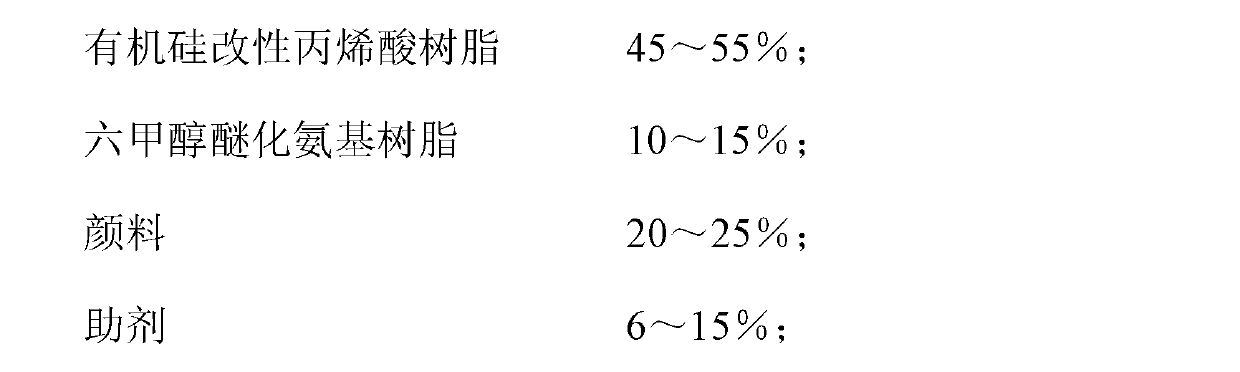

[0026] A silicone modified acrylic resin primer for plastic parts. The primer is composed of silicone modified acrylic resin, hexamethanol etherified amino resin, pigments, additives and solvents. The weight percentage of each component is:

[0027]

[0028] When preparing, weigh each raw material according to the proportion, first add the silicone modified acrylic resin to the dispersant and stir evenly, add the pigment and solvent while stirring, disperse and grind until the fineness is less than 20 microns, and add the flow after cooling. For leveling agent, just stir evenly.

[0029] The properties of the product prepared in this embodiment are as follows:

[0030]

Embodiment 2

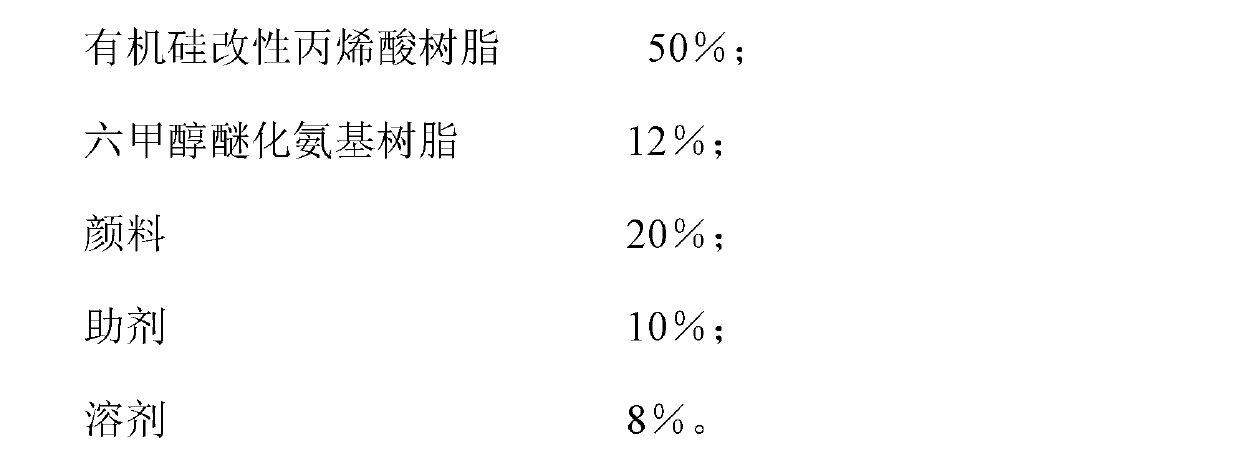

[0032] A silicone modified acrylic resin primer for plastic parts. The primer is composed of silicone modified acrylic resin, hexamethanol etherified amino resin, pigments, additives and solvents. The weight percentage of each component is:

[0033]

[0034] When preparing, weigh each raw material according to the proportion, first add the silicone modified acrylic resin to the dispersant and stir evenly, add the pigment and solvent while stirring, disperse and grind until the fineness is less than 20 microns, and add the flow after cooling. For leveling agent, just stir evenly.

Embodiment 3

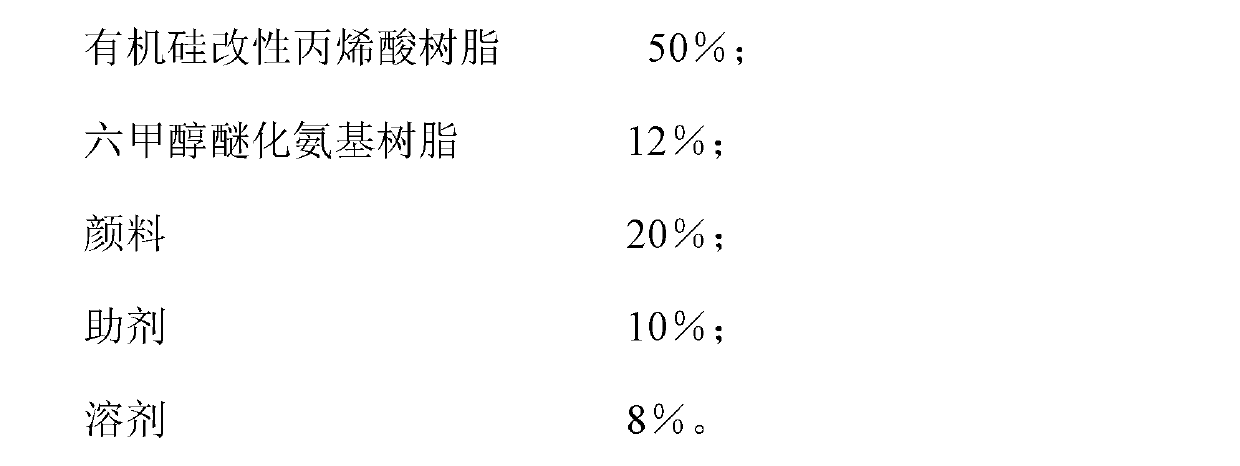

[0036] A silicone modified acrylic resin primer for plastic parts. The primer is composed of silicone modified acrylic resin, hexamethanol etherified amino resin, pigments, additives and solvents. The weight percentage of each component is:

[0037]

[0038] When preparing, weigh each raw material according to the proportion, first add the silicone modified acrylic resin to the dispersant and stir evenly, add the pigment and solvent while stirring, disperse and grind until the fineness is less than 20 microns, and add the flow after cooling. For leveling agent, just stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com