Cleaning method and cleaning device for brazing filler metal extruded wire

A cleaning device and wire material technology, which is applied in the coating process of metal materials, etc., can solve the problems of difficult large-scale cleaning in batches, increased use of chemicals, expensive ultrasonic equipment, etc., and achieves simple structure, low cost, The effect of reducing acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

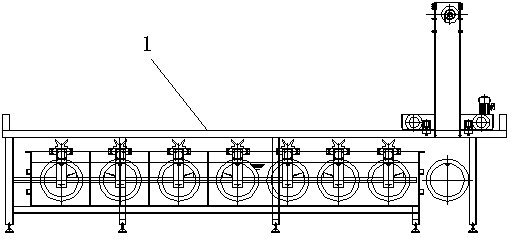

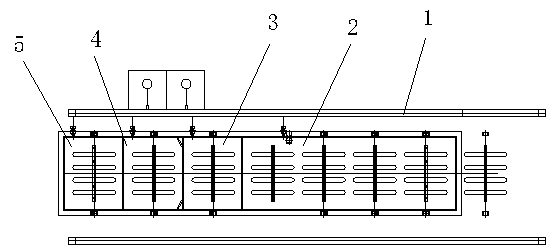

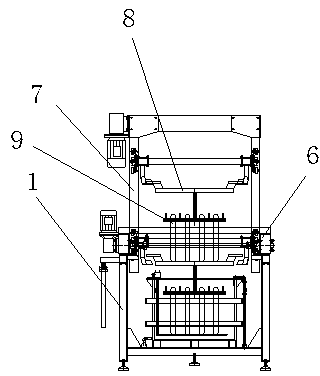

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] The cleaning method of solder extruded wire in the present embodiment is characterized in that comprising the following steps:

[0024] 1) Soak the coiled extruded wire in 15-20% (mass percentage) acid solution for 15-30 minutes to remove scale; input the program on the man-machine interface of the electrical control system, and put the coiled solder Put the extruded wire 9 on the suspension rod, turn on the start button, and the transmission device will automatically send the extruded wire 9 and the suspension rod into the deoxidation tank 2 through the frame platform 1, soak for 15-30 minutes, and deoxidize the tank 2 It contains an acid solution with a mass percentage concentration of 15-20%.

[0025] 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com