Underwater training space suit dryer based on heat pump technology

A heat pump technology and space suit technology, applied in the field of drying and heat recovery, can solve the problems of inapplicability of space suits and insufficient utilization of system energy, so as to improve dehumidification efficiency and equipment utilization, reduce dehumidification energy consumption and Operating cost and effect of reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

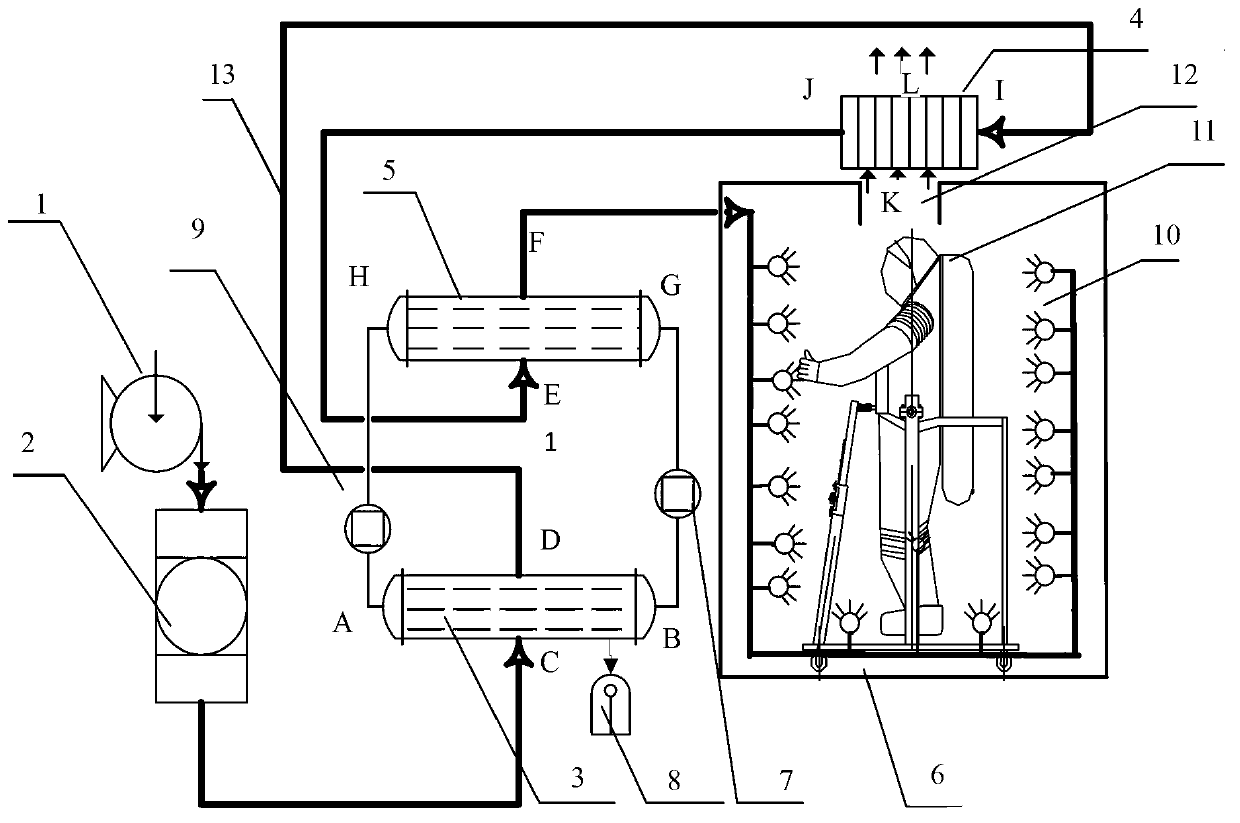

[0026] Such as figure 1 Shown is an underwater training spacesuit dryer using heat pump technology, including a heat pump system for refrigerant circulation and a working air handling system;

[0027] The heat pump system of the refrigerant cycle includes a compressor 7, an air heater 5, a throttling device 9, an air cooler 3 and a closed metal copper tube;

[0028] The working air treatment system includes induced draft fan 1, air filter 2, air cooler 3, waste heat recovery device 4, air heater 5, drying chamber 6, drying nozzle 10 and air duct;

[0029] The air cooler 3 and the air heater 5 have the same structure, and are composed of a shell and copper tubes inside the shell. The bottom and top of the shell are respectively provided with an air inlet and an air outlet, and the two ends of the copper tube have an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com