Self-pressurization device for vehicle gas cylinder

A self-pressurization, gas cylinder technology, applied in the direction of oil supply device, charging system, internal combustion piston engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

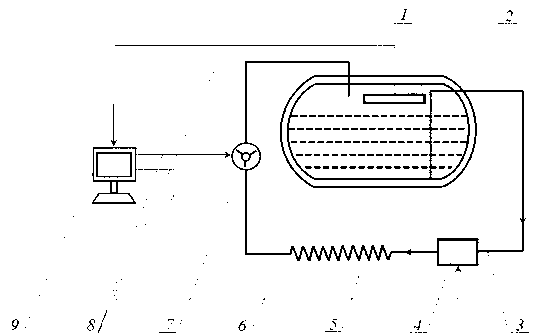

[0030] Such as figure 1 As shown, before starting the engine, the control system 9 is turned on, the pressure sensor 2 detects the pressure in the gas cylinder 1, and the detection signal is fed back to the control system 9 through the electrical signal system 8. When the detected pressure in the gas cylinder 1 is lower than When the start-up pressure required by the engine is 0.55 MPa, the control system 9 automatically calculates an optimized liquid intake flow rate, and issues instructions to the electric valve assembly 4, so that the electric valve assembly 4 is in a corresponding opening degree, and then the control system 9 controls the air pump 7 sends out a forward rotation trigger signal, LNG passes through the liquid extraction pipeline 3 under the action of the air pump 7, flows through the electric valve assembly 4, and enters the vaporizer 5 with the optimized liquid extraction flow rate automatically calculated by the control system 9, and the vaporized LNG Ente...

Embodiment 2

[0032] When the engine is running, when the vehicle is driving on flat ground, the control system sets the hydraulic supply pressure of the engine to 0.5MPa, and sets a high pressure threshold of 0.6MPa and a low pressure threshold of 0.48MPa. Since the pressure in the gas cylinder 1 will be lost during the operation of the engine, the control system 9 automatically sets the optimized liquid flow rate according to the running state of the vehicle, and controls the continuous operation of the air pump 7 and the opening degree of the electric valve assembly 4 to optimize the flow rate. The flow rate of liquid taken from the cylinder flows into the carburetor 5 to continuously supplement the lost pressure, thus avoiding the frequent opening and closing of the air pump 7 and the electric valve assembly 4, and improving the service life of these components. When the pressure in the gas cylinder 1 is higher than the control system 9 setting When the high pressure threshold is 0.6MPa,...

Embodiment 3

[0034] When the vehicle stops, the engine is closed, and now the control system 9 sends a reverse command to the air pump 7, and the air pump 7 presses the remaining LNG in the liquid extraction pipeline 3 back to the gas cylinder 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com