Coupling mechanism of shafts

A technology of coupling mechanism and driven shaft, which is applied to rigid shaft couplings, couplings, mechanical equipment, etc., can solve the problems of difficulty in meeting precision requirements, affecting service life, and difficulty in keyway processing, so as to reduce operation difficulty, The effect of shortening the working time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

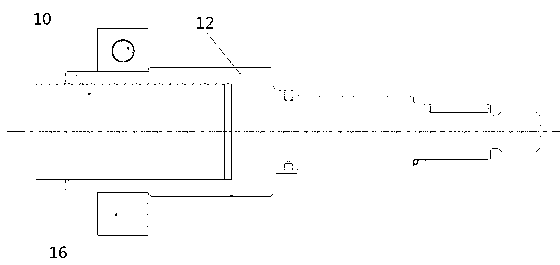

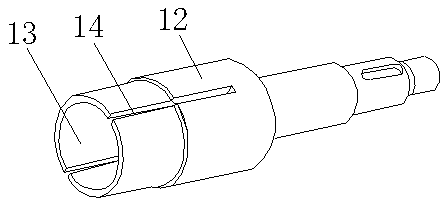

[0016] see Figure 2 to Figure 5 As shown, a shaft-to-shaft coupling mechanism of the present invention includes a driving shaft 10, a driven shaft 12 and a locking sleeve 16, wherein the end of the driven shaft 12 has a cavity 13 for accommodating the end of the driving shaft 10 (see image 3 ), the container 13 fits in shape with the end of the driving shaft 10. The special feature of the present invention is that two opening grooves 14 are provided on the side wall of the container 13 at intervals along its length (see image 3 ), the two open slots 14 are oppositely arranged, and the side wall of the container is divided into two parts arranged at intervals, and a locking sleeve 16 is set on the wall of the container. When in use, firstly, the end of the drive shaft 10 Extend into the slot 13 of the driven shaft 12, and then tighten th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com