Optical fiber concrete freezing-thawing expansion strain monitoring sensor

A technology for monitoring sensors and expansion strains, applied in instruments, measuring devices, optical devices, etc., can solve the problems of difficult measurement of freeze-thaw expansion damage, and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

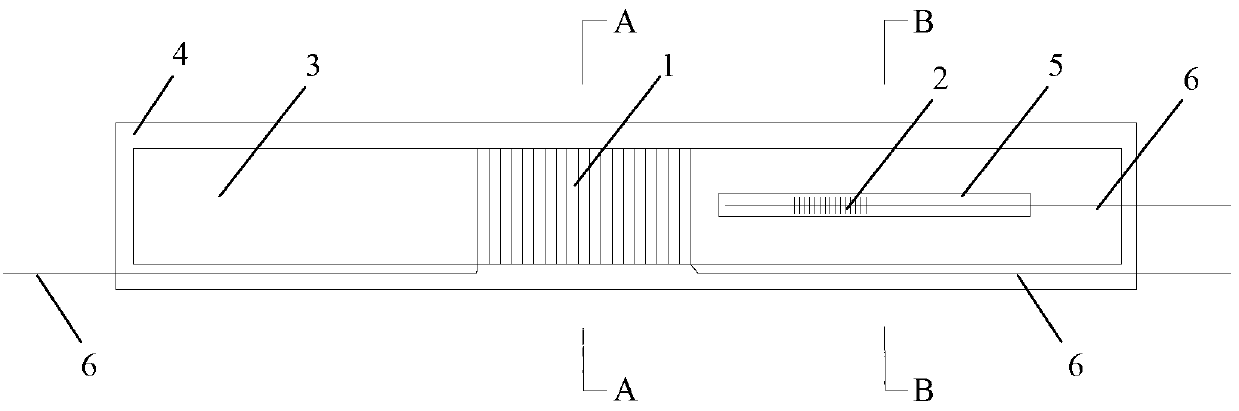

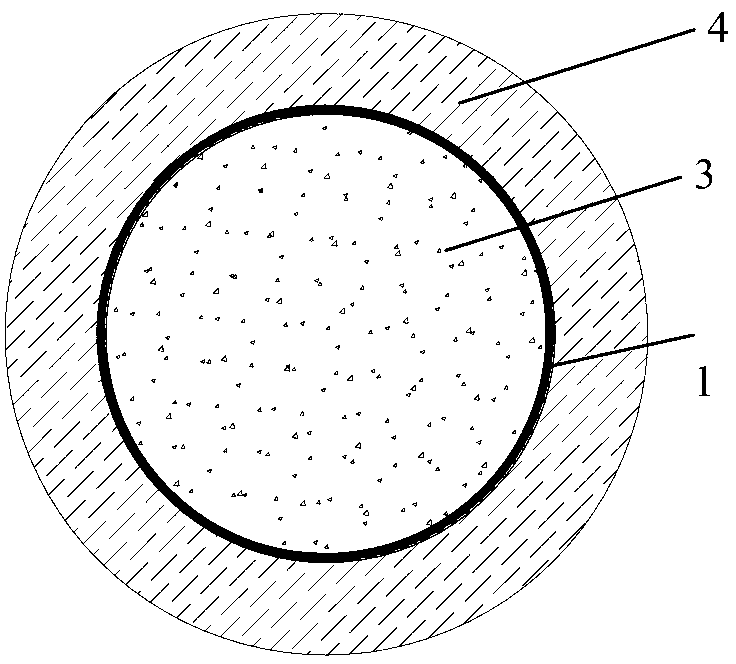

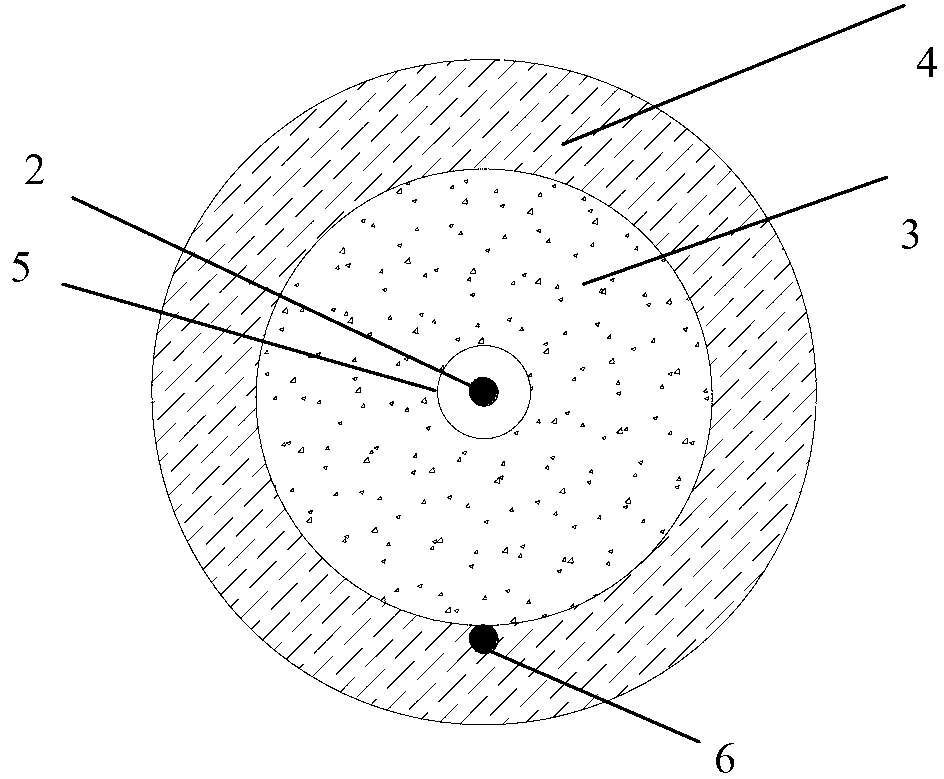

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0018] The packaging structure of the fiber optic concrete freeze-thaw expansion strain monitoring sensor includes: a single-mode anti-bending optical fiber winding coil, a temperature compensation fiber grating, a fine aggregate concrete cylinder, a cement mortar protective layer, a steel pipe, and an optical cable.

[0019] First of all, use the mold or drilling sampling method to make a concrete cylinder with the same material ratio as the concrete to be tested. The diameter of the cylinder is 5-8cm, and the specific diameter can be selected according to the specific concrete measurement point. The steel pipe used to protect the temperature compensation fiber grating is pre-embedded in the position of the cylinder. During the production process of the cylinder, the temperature compensation fiber Bragg grating is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com