Temperature measuring system

A technology of temperature measurement and detection holes, applied in the field of detection, can solve the problems of poor timeliness of temperature detection, unreliable reflection of the real temperature in the kiln, lagging operation status of the rotary kiln, etc., and achieve the effect of improving timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the solution of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation manners.

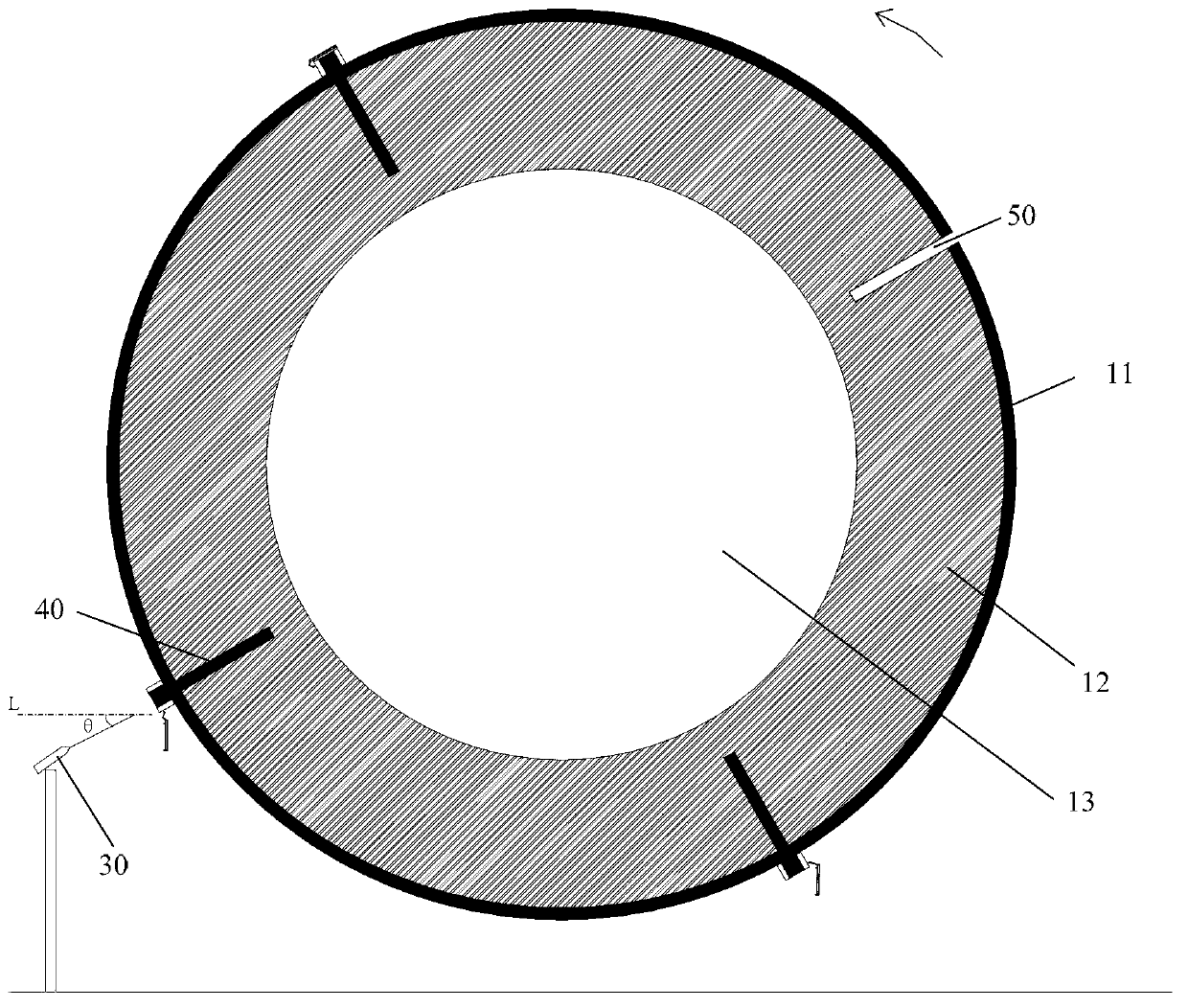

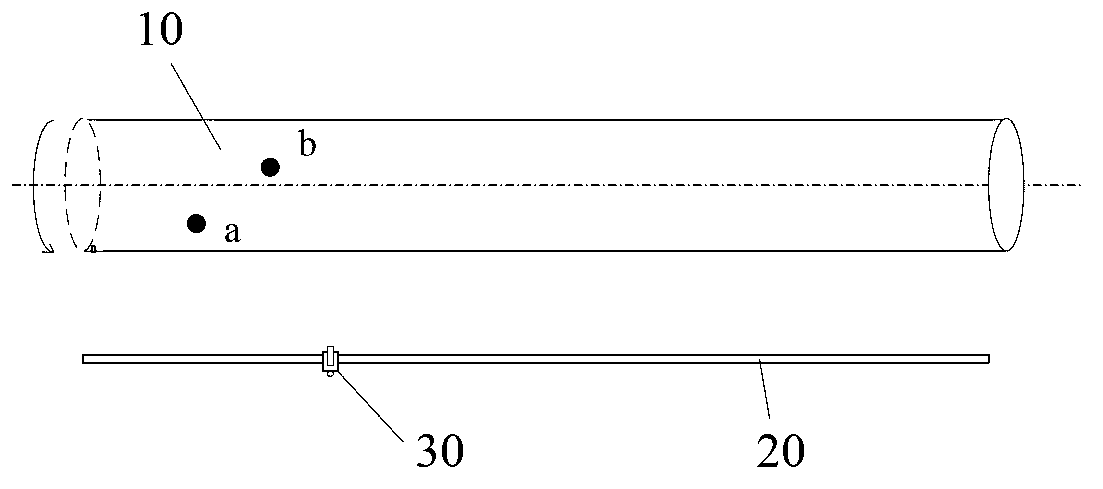

[0042] Combine first figure 1 Briefly introduce the composition of the rotary kiln. The figure shows a schematic diagram of the circumferential cross-section of the rotary kiln. The rotary kiln operates in the direction of the arrow in the figure. From the outside to the inside, it can include a steel kiln shell 11 and a furnace lining 12 formed of refractory materials. , and the kiln cavity 13 formed by the kiln shell and the furnace lining for holding materials. In order to ensure the calcination process and the normal operation of the rotary kiln, the temperature in the kiln should be monitored and controlled at any time. However, the rotary operation of the rotary kiln brings great difficulties to the measur...

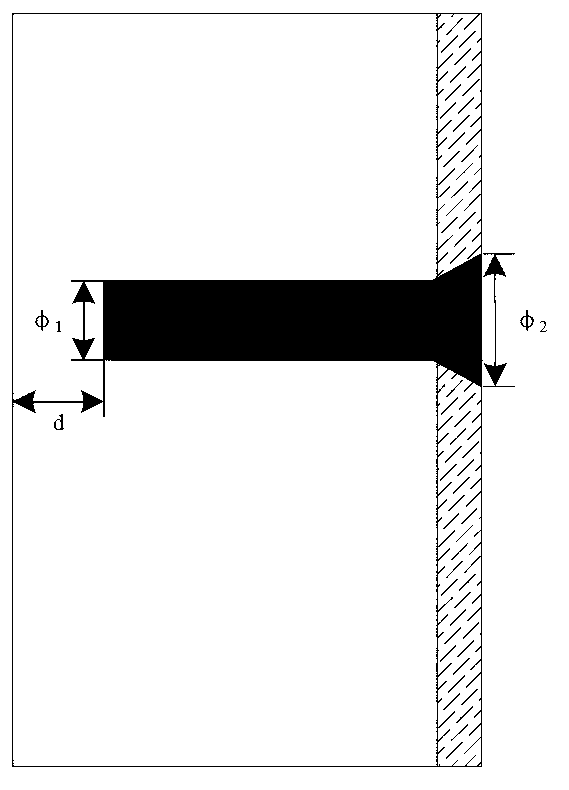

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com