Standard plane type ultra-precise direct-drive hydrostatic spindle dynamic property on-line testing method

A technology of hydrostatic spindle and dynamic performance, which is used in the testing of mechanical parts, the testing of machine/structural parts, and measuring devices, etc., can solve the problem of inability to realize the online test of dynamic performance of ultra-precision hydrostatic spindle, and achieve accurate measurement results. Reliable, high measurement accuracy, simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

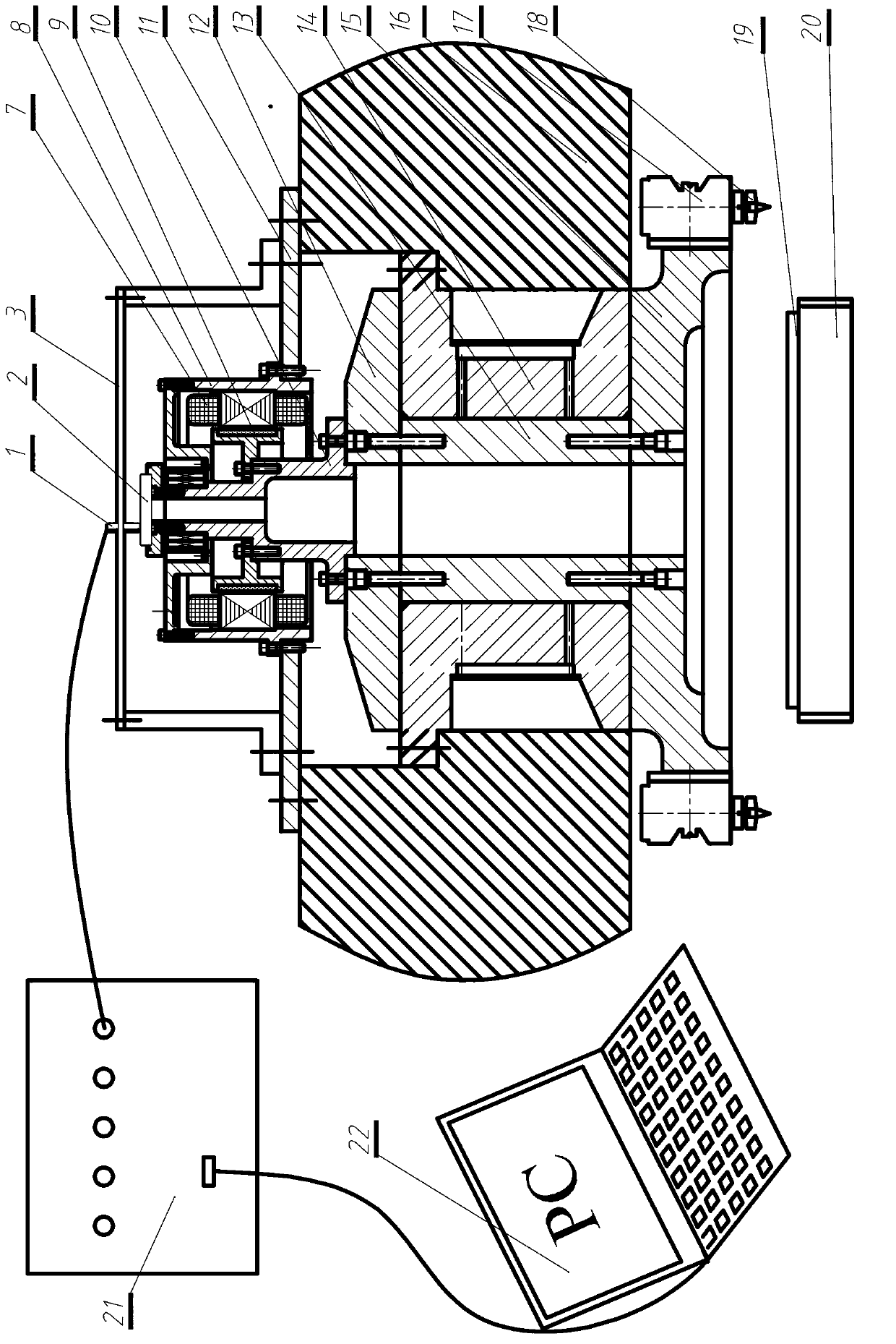

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, the online testing method described in this embodiment is based on including vertical ultra-precision direct drive hydrostatic spindle system, measurement system and computer data acquisition and processing system 22 to realize;

[0009] The vertical ultra-precision direct-drive hydrostatic spindle system includes a servo motor, an ultra-precision direct-drive hydrostatic spindle (rotating part, namely the rotor part), a machine tool beam support plate (machine tool beam cover plate) 11, a spindle bushing 14 (stator Part), machine beam 16, micro-feed tool holder 17 and diamond tool 18; the ultra-precision direct-drive static pressure spindle consists of an input end component 10, an upper thrust plate 12, and a shaft center 13 coaxially arranged from top to bottom , the lower thrust plate 15 is fixedly connected; the servo motor includes a motor stator 7, a motor rotor 9 and a casing 8; the mea...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the standard plane 2 of this embodiment is an optical flat crystal, the PV value of the surface shape accuracy is better than λ / 20 (where λ=0.633 μm), and the RMS value of the surface roughness is better than 2nm. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 The present embodiment is described. The surface of the high-precision standard plane 2 in this embodiment is coated with a metal film, and the plated metal is gold, silver, copper or nickel. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com