On-line testing method of hydrostatic spindle motion accuracy based on laser dynamic interferometer

A technology of dynamic interference and static pressure spindle, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of low accuracy of results, failure to reflect the real state and dynamic performance of ultra-precision spindles, etc. Achieve accurate and reliable measurement results, simple and easy method, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

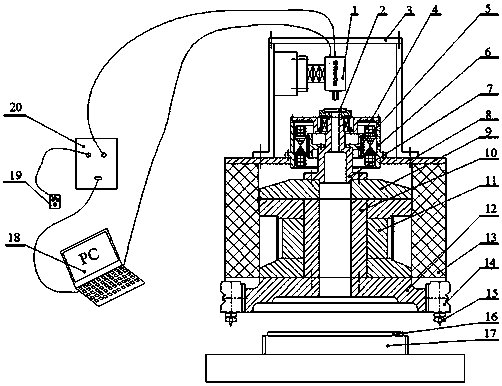

[0029] combine figure 1 Describe this embodiment, the laser dynamic interferometer 1 of this embodiment is a Tieman Green type laser interferometer that is not sensitive to vibration, the measurement mode adopts a high-speed optical phase sensor, the acquisition rate is >10 frames / s, and 4000 interferograms / frame , the minimum exposure time is 30μs, the maximum exposure time is 1μs, the RMS repeatability is less than 0.633nm, and the RMS accuracy is less than 1.25nm.

specific Embodiment approach 3

[0030] combine figure 1 To illustrate this embodiment, the high-precision standard flat crystal 2 of this embodiment is an optical flat crystal, the PV value of the surface shape accuracy is less than λ / 50, where λ=0.633 μm, and the RMS value of the surface roughness is less than 2 nm.

specific Embodiment approach 4

[0031]The surface of the high-precision standard flat crystal 2 of this embodiment is coated with a metal film, and the metal is gold, silver, copper or nickel; other compositions and connections are the same as those in Embodiment 2 or 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com