Free space terminal short-circuit system for temperature changing measurement of dielectric property of dielectric material

A technology of dielectric materials and dielectric properties, applied in the measurement of electrical variables, resistance/reactance/impedance, measurement devices, etc., can solve the problems of low test efficiency, cumbersome calibration, and difficulty, so as to reduce the time spent and reduce The number of measurements, the effect of reducing calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

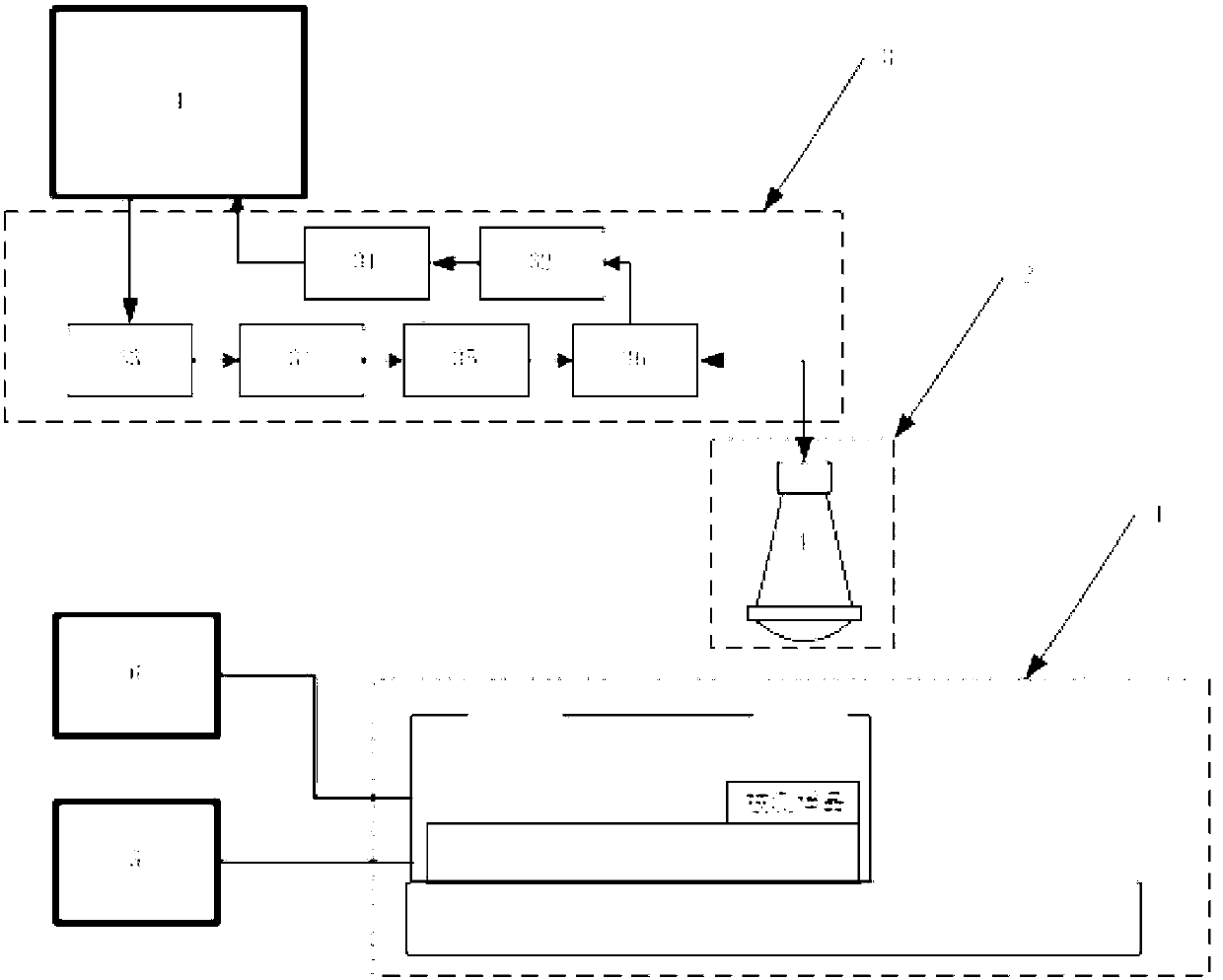

[0036] Free space terminal short-circuit system for variable temperature testing of dielectric properties of dielectric materials, such as figure 1 As shown, it includes a material heating system 1, a millimeter-wave broadband conical horn antenna 2, a signal energy transmission and receiving system 3, a vector network analyzer 4, a water cooling system 5, and a vacuum system 6.

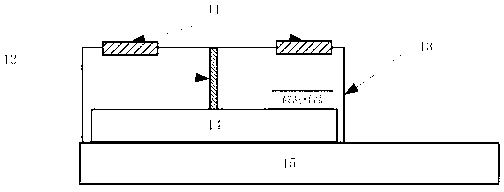

[0037] The material heating system 1 adopts a mobile vacuum platform structure, and the system includes two quartz lenses 111 and 112 , a vacuum cover 13 , an electromagnetic induction heating device 14 and a mobile platform 15 . Two identical quartz lenses 111 and 112 are symmetrically mounted on the center line of the top broadside of the vacuum cover 13 (that is, the geometric centers of the quartz lenses 111 and 112 are located on the center line of the top wide side of the vacuum cover 13, and about the wide side of the top of the vacuum cover 13 The midpoint of the midline is symmetrical); the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com