Non-destructive power MOS tube single-event burnout effect detecting circuit and non-destructive power MOS tube single-event burnout effect detecting method

A single-particle burning, MOS tube technology, applied in the direction of single semiconductor device testing, etc., can solve the problems that cannot be repeated many times, cannot determine the threshold value of the gate control voltage and drain voltage of the MOS tube, etc., and achieves simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

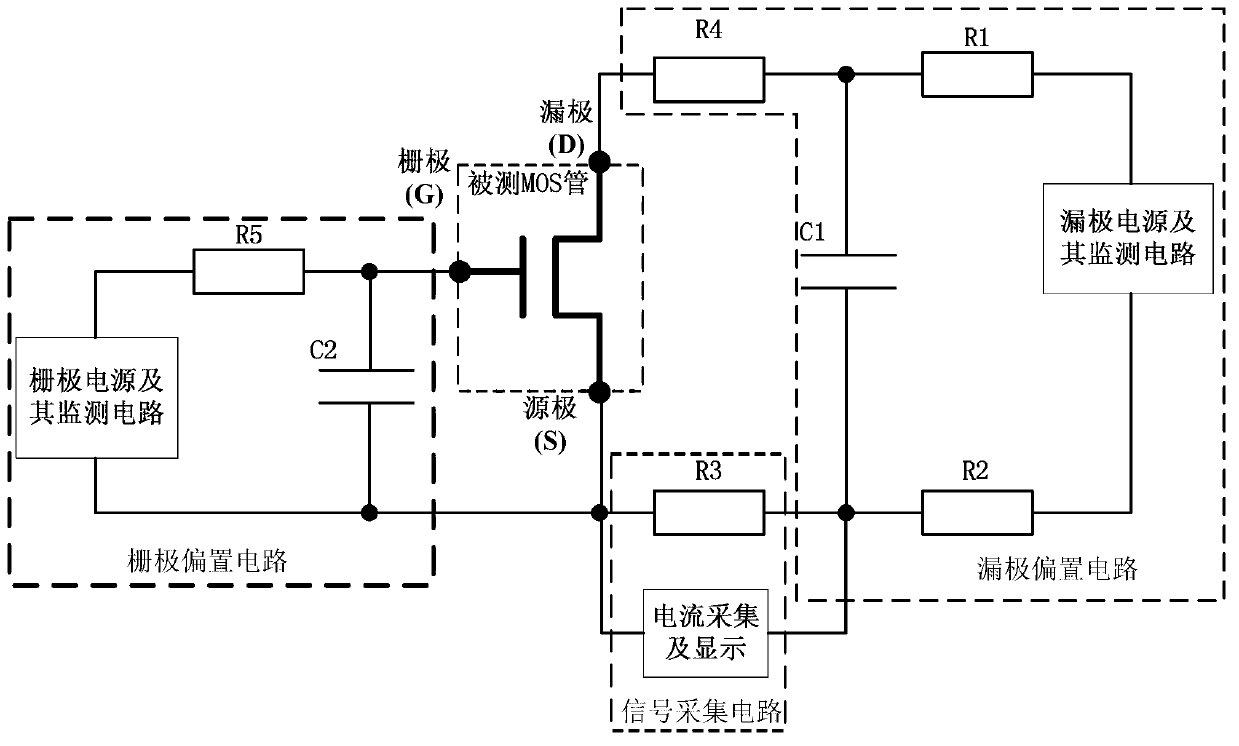

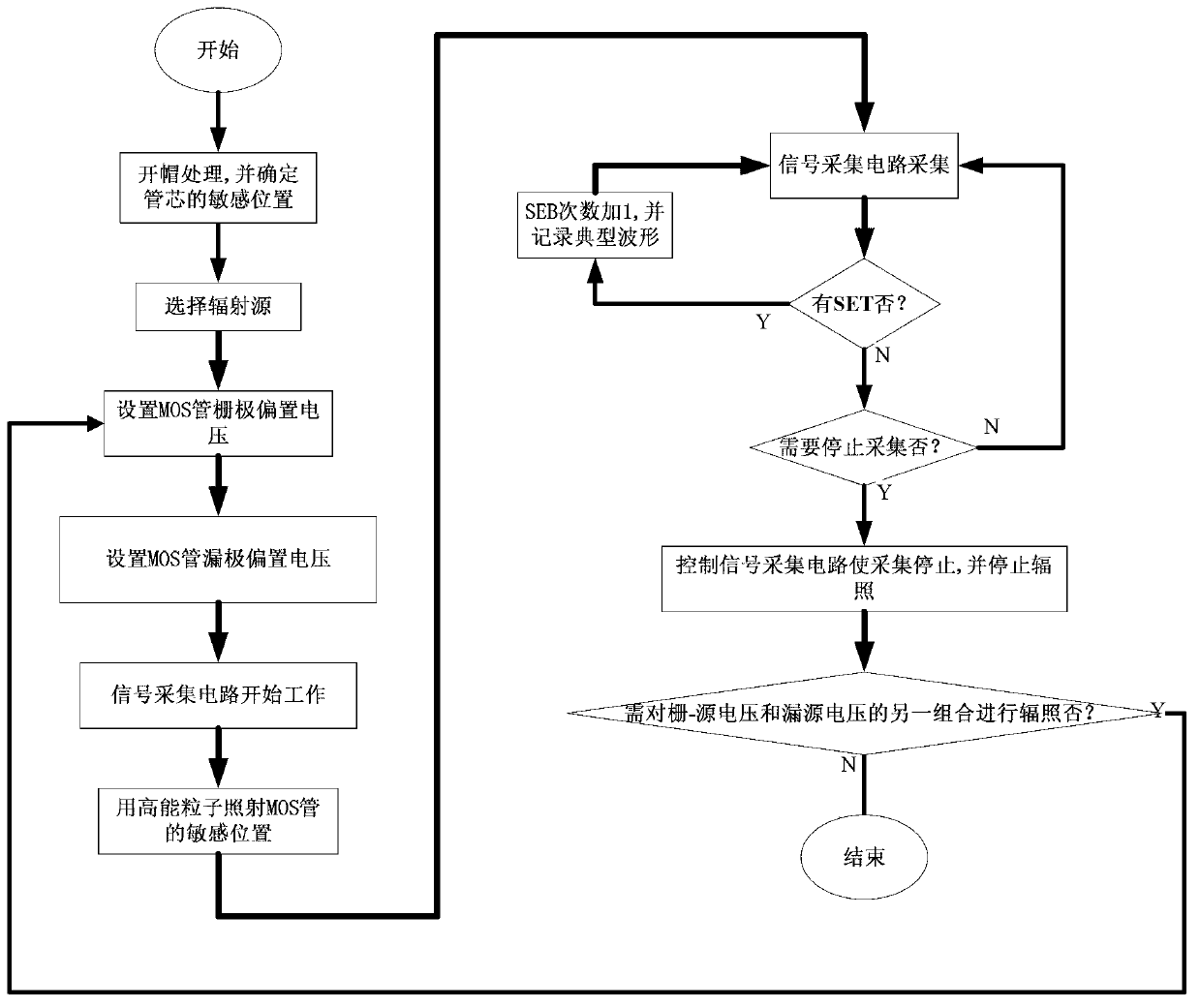

[0026] The invention provides a non-destructive power MOS tube single-event burnout (SEB, single-event burnout) detection circuit and detection method, the circuit is as follows figure 1 As shown, the circuit includes: a gate bias circuit, a drain bias circuit and a signal acquisition circuit.

[0027] The gate bias circuit includes a gate power supply, a gate power supply monitoring circuit, a resistor R5 and a capacitor C2, and the drain bias circuit includes a drain power supply, a drain power supply monitoring circuit, resistors R1, R2, R4 and a capacitor C1, and the signal acquisition The circuit includes a current acquisition display circuit and a resistor R3;

[0028] The positive pole of the gate power supply is connected to the gate of the MOS tube under test through the resistor R5. At the same time, the gate of the MOS tube under test is also connected to the negative pole of the gate power supply and the source of the MOS tube under test through the capacitor C2, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com