Phase-change memory unit and preparation method thereof

A phase-change storage and phase-change material technology, applied in the field of two-dimensional phase-change storage units and their preparation, can solve the problems of phase-change storage failure, slow operation speed, and high power consumption, and achieve the ability to increase the number of cycle operations and reduce Damage, low power effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

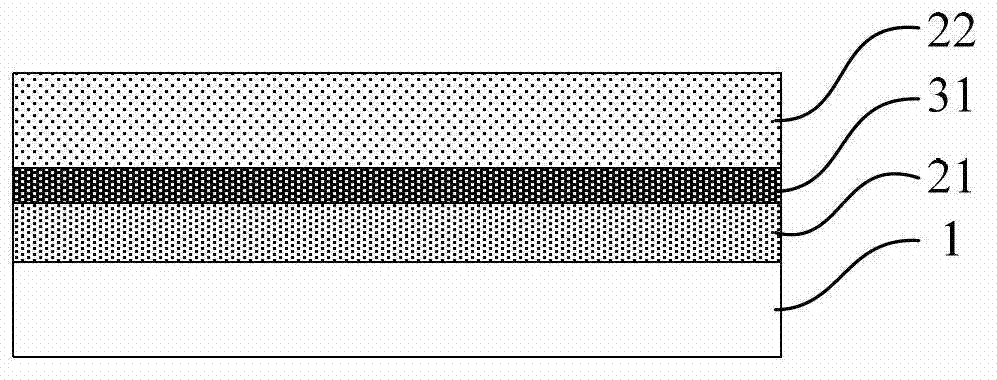

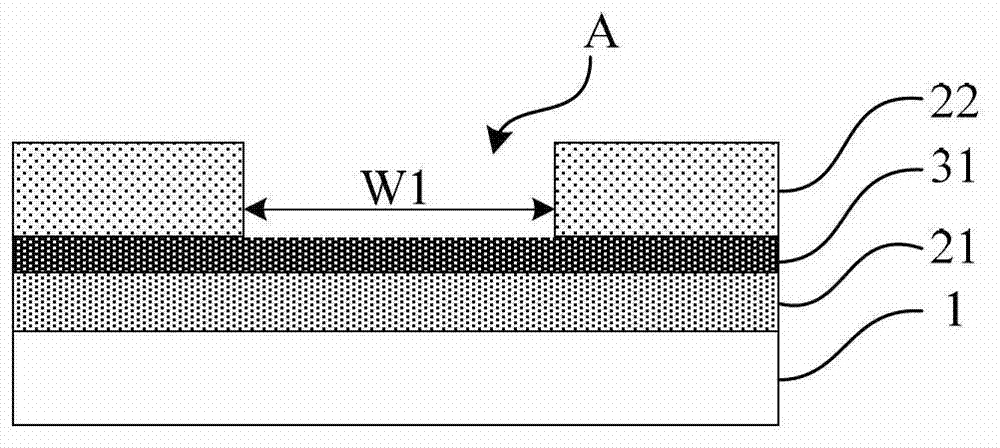

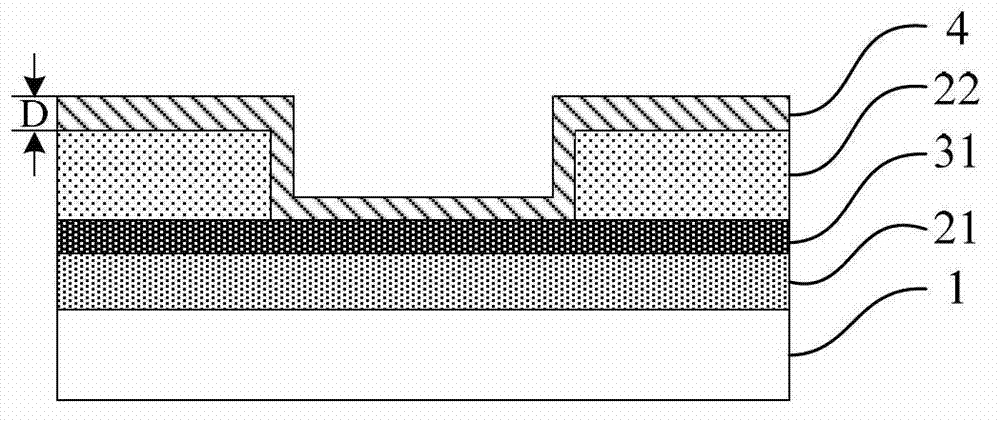

[0080] see Figure 1G , the present invention provides a phase change memory cell, comprising at least: Si substrate 1, first dielectric material layer 21, lower electrode layer 31, second dielectric material layer 22, phase change material layer 4, third dielectric material layer 23 And the upper electrode layer 32.

[0081] The first dielectric material layer 21 is formed on the surface of the Si substrate; the lower electrode layer 31 is formed on the surface of the first dielectric material layer 21 .

[0082] The upper surfaces of the second dielectric material layer 22, the phase change material layer 4 and the third dielectric material layer 23 are all located on the same plane, and at the same time, the second dielectric material layer 22, the phase change material layer 4 and the third dielectric material layer The layers 23 are all formed on the lower electrode layer 31 and are in contact with the lower electrode layer 31 .

[0083] The phase-change material layer ...

Embodiment 2

[0116] like Figure 2D As shown, the present invention provides a phase-change memory cell, which at least includes: a Si substrate 1 , a second dielectric material layer 22 , an electrode pair 5 , a phase-change material layer 4 and a third dielectric material layer 23 . in, Figure 2D It is a schematic structural diagram of a phase change memory cell in this embodiment.

[0117] The second dielectric material layer 22 is formed on the surface of the Si substrate 1 . Wherein, the second dielectric material layer 22 is an oxygen-free semiconductor dielectric material, at least including any one of gallium nitride, germanium nitride or silicon nitride. In this embodiment it is silicon nitride.

[0118] The electrode pair 5 is formed on the surface of the second dielectric material layer 22 , and two electrodes in the electrode pair 5 have a first distance and are separated from each other. Wherein, the range of the first distance is 10-100 nanometers, in this embodiment, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com