Vanilla crackling sausage and preparation method thereof

A production method and a technology for crispy sausages, which are applied in food preparation, application, food science and other directions, can solve the problems of affecting the absorption of nutrients, greasy taste, and the fragrance is not directly round enough, and achieve a reasonable combination of meat and vegetables, good sliceability, and taste. Moderate salty and sweet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

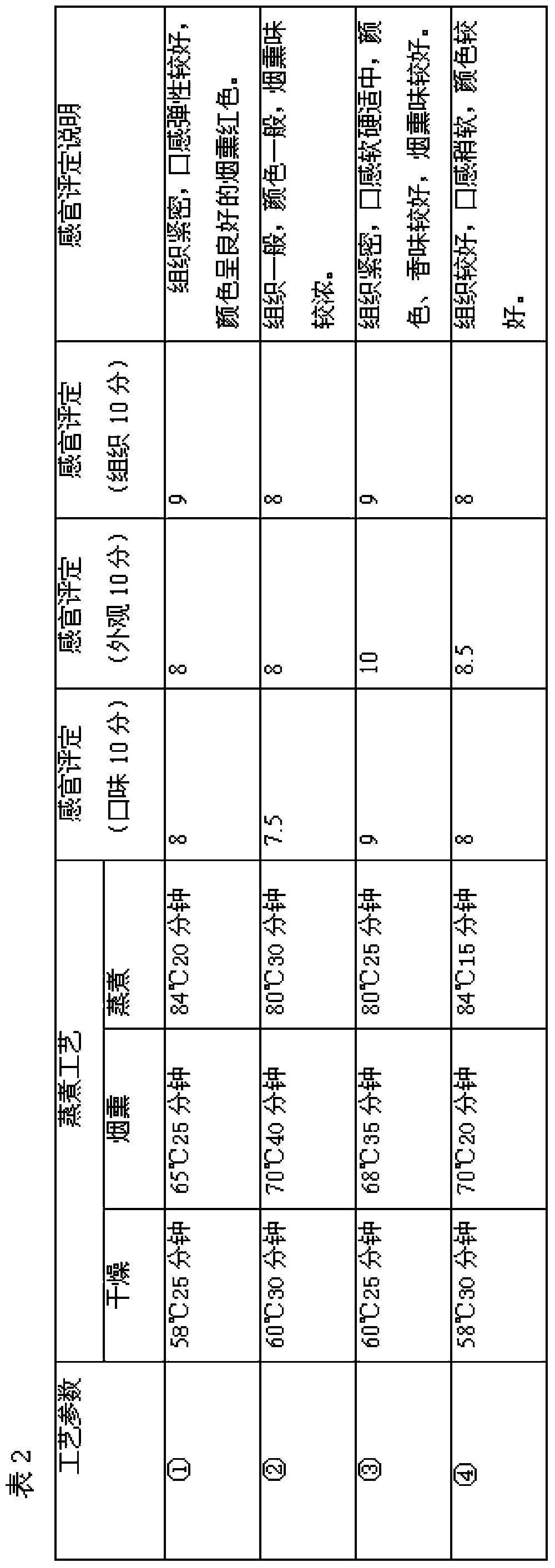

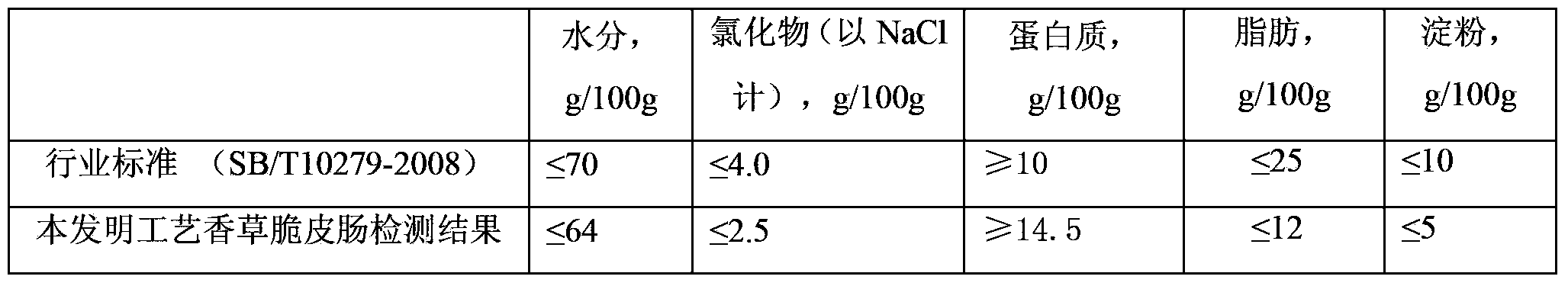

Examples

Embodiment 1

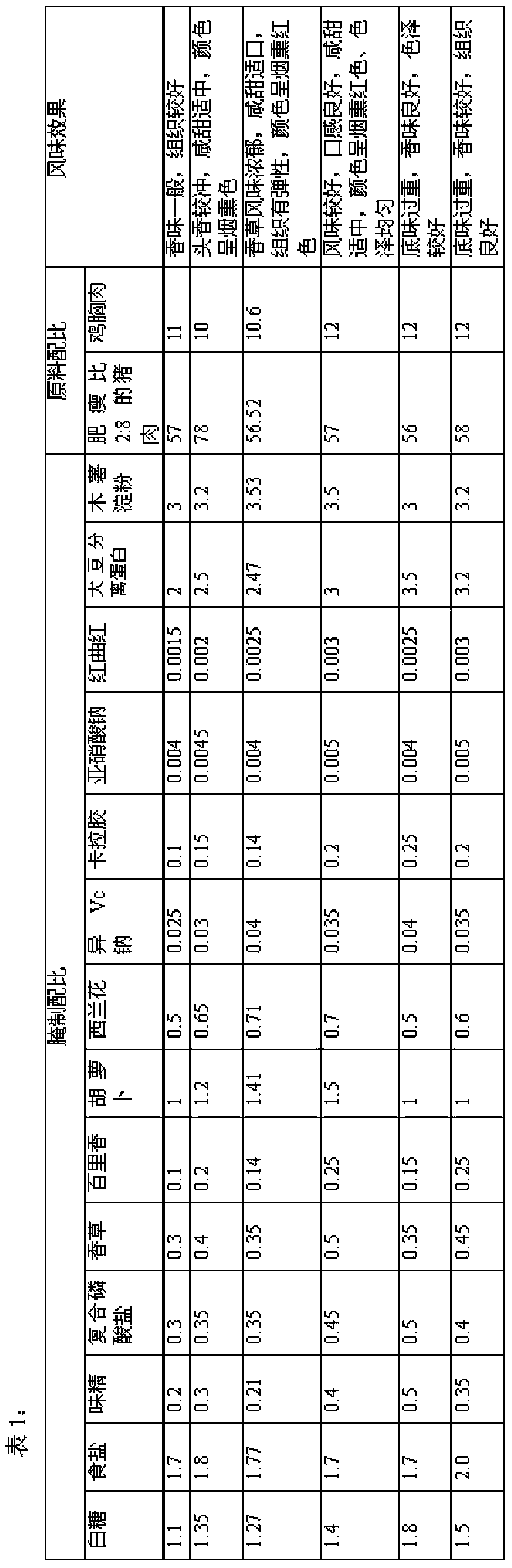

[0046] formula:

[0047] 1. Thawing: Thaw chicken breast meat and pork with a fat-to-lean ratio of 2:8, thaw naturally at an ambient temperature of ≤15°C, or thaw with water until the center temperature is -2-0°C.

[0048] 2. Segmentation: Remove the fascia and large pieces of fat from the thawed pork, and divide it into 200-400g / piece.

[0049] 3. Grinding: Grinding pork and chicken breast meat with a meat grinder, and chopping carrots and broccoli into 3-5mm granules with a chopping machine. Wherein the pork and the chicken breast are ground with a 6mm orifice plate.

[0050] 4. Pickling: Take 56.52 parts by weight of twisted pork, 10.6 parts by weight of chicken breast, add 1.77 parts by weight of table salt, 1.27 parts by weight of white sugar, 0.21 parts by weight of monosodium glutamate, 0.35 parts by weight of compound phosphate, 0.35 parts by weight of vanilla, thyme 0.14 parts by weight, 1.41 parts by weight of carrots, 0.71 parts by weight of broccoli, 0.04 parts b...

Embodiment 2

[0058] formula:

[0059] 1. Thawing: Thaw chicken breast meat and pork with a fat-to-lean ratio of 2:8, thaw naturally at an ambient temperature of ≤15°C, or thaw with water until the center temperature is -2-0°C.

[0060] 2. Segmentation: Remove the fascia and large pieces of fat from the thawed pork, and divide it into 200-400g / piece.

[0061] 3. Grinding: Grinding pork and chicken breast meat with a meat grinder, and chopping carrots and broccoli into 3-5mm granules with a chopping machine. Wherein the pork and the chicken breast are ground with a 6mm orifice plate.

[0062] 4. Pickling: Take 56 parts by weight of twisted pork, 11 parts by weight of chicken breast, add 1.7 parts by weight of salt, 1.2 parts by weight of white sugar, 0.2 parts by weight of monosodium glutamate, 0.35 parts by weight of compound phosphate, 0.4 parts by weight of vanilla, thyme 0.25 parts by weight, 1.5 parts by weight of carrots, 0.5 parts by weight of broccoli, 0.03 parts by weight of sodiu...

Embodiment 3

[0070] 1. Thawing: Thaw chicken breast meat and pork with a fat-to-lean ratio of 2:8, thaw naturally at an ambient temperature of ≤15°C, or thaw with water until the center temperature is -2-0°C.

[0071] 2. Segmentation: Remove the fascia and large pieces of fat from the thawed pork, and divide it into 200-400g / piece.

[0072] 3. Grinding: Grinding pork and chicken breast meat with a meat grinder, and chopping carrots and broccoli into 3-5mm granules with a chopping machine. Wherein the pork and the chicken breast are ground with a 6mm orifice plate.

[0073] 4. Pickling: Take 57 parts by weight of twisted pork, 12 parts by weight of chicken breast, add 1.8 parts by weight of table salt, 1.35 parts by weight of white sugar, 0.2 parts by weight of monosodium glutamate, 0.35 parts by weight of compound phosphate, 0.3 parts by weight of vanilla, thyme 0.1 parts by weight, 1 part by weight of carrot, 0.65 parts by weight of broccoli, 0.03 parts by weight of sodium iso-Vc, 0.15 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com