Strongly magnetic vortex sorter

An eddy current separation and strong magnetic technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of the separation material spilling on the ground, affecting the working environment, etc., and achieve the effect of reducing the size and increasing the size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

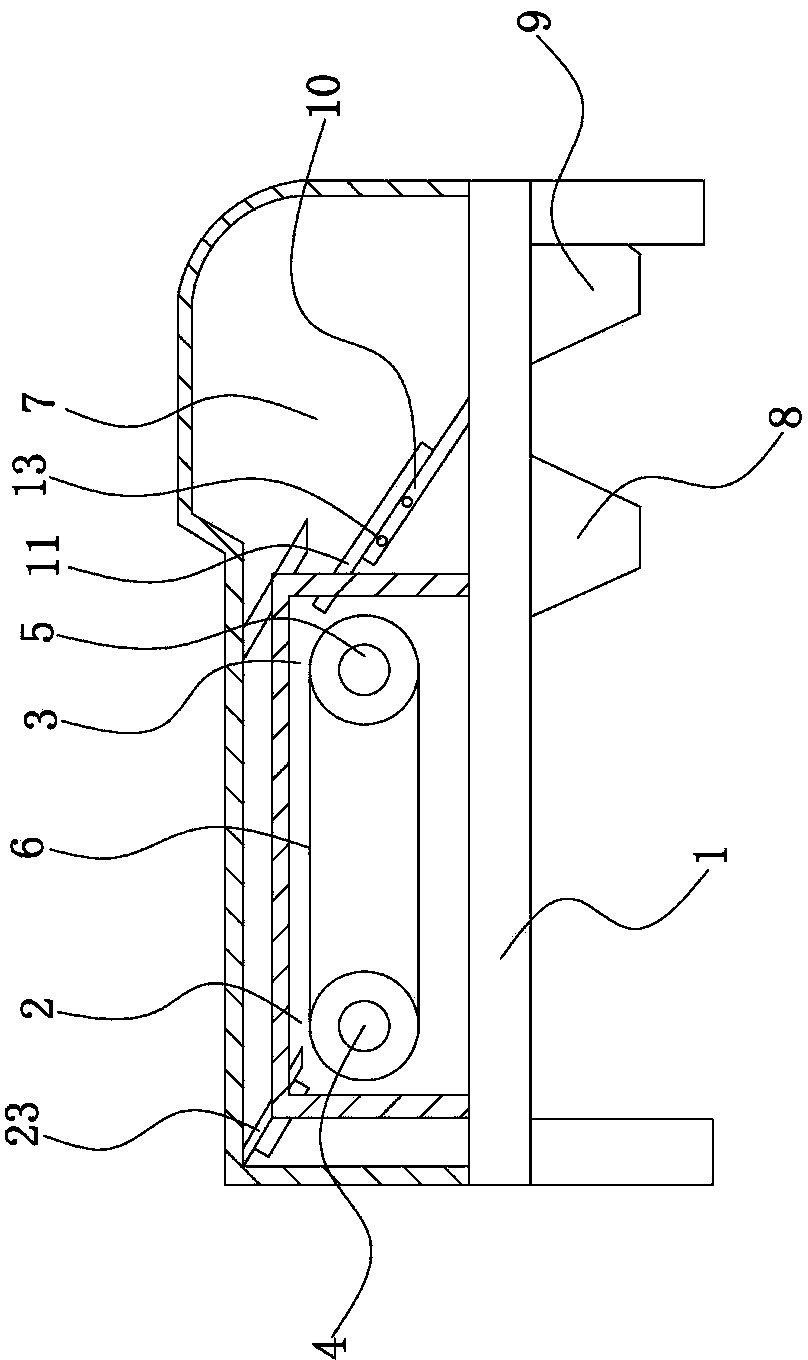

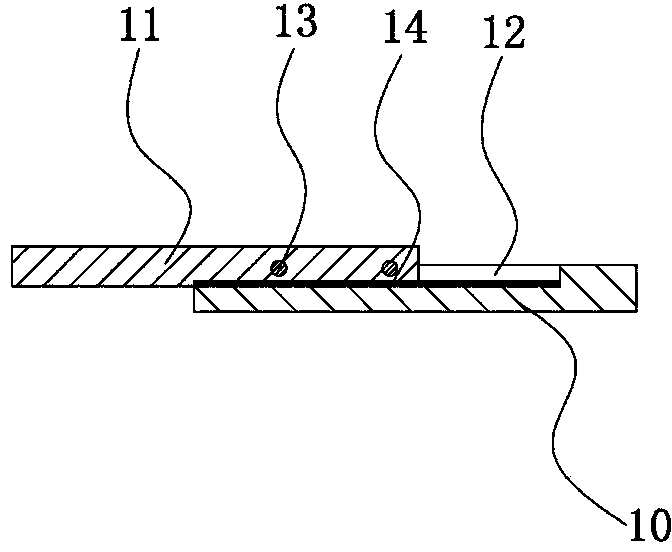

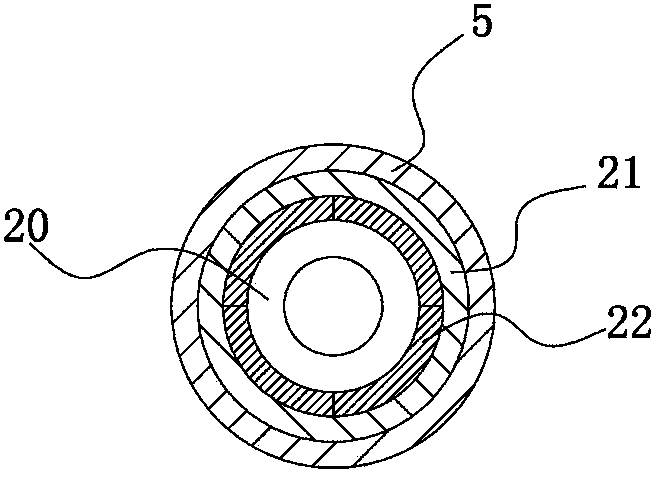

[0025] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the strong magnetic eddy current separator is mainly composed of a base 1, on which an inlet 2 and an outlet 3 are arranged, and on the base 1 at the inlet 2, a motor is arranged. The rotating shaft 4 is provided with a rotating roller 5 parallel to the rotating shaft 4 on the base 1 at the outlet 3, and a conveyor belt 6 is connected between the rotating shaft 4 and the rotating roller 5. The seat 1 is also provided with a material distribution chamber 7, and the material distribution chamber 7 is obliquely provided with a discharge plate 10 that separates the material distribution chamber 7 into the material distribution port 1 8 and the material distribution port 2 9. The inclination direction of the discharge plate 10 is located in the tangential direction of the discharge port end of the above-mentioned conveyor belt 6. On the discharge plate 10 near the end of the discharge port 3, there is a slid...

Embodiment 2

[0029] Such as figure 1 or Figure 5 As shown, the structure of this implementation is basically the same as that of Embodiment 1, the difference is that the adjustment device is mainly provided with a rectangular partition plate 15 on the discharge plate, and the tangent line along the discharge port end of the conveyor belt 6 on the rectangular partition plate 15 The direction is provided with several strip holes, and the rectangular partition plate 15 is fixed on the above-mentioned discharge plate 10 through the above-mentioned strip holes by bolts; the strip hole includes a strip hole one 16, Strip hole two 17, strip hole three 18 and strip hole four 19, described strip hole one 16 and strip hole two 17 are parallel to each other, and the strip hole three 18 and strip hole one 16 are arranged in a straight line , the strip hole four 19 and the strip hole two 17 are arranged in a straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com