Pneumatic plate shearing machine

A technology of pneumatic shears and plate shears, which is applied in the direction of shearing machine equipment, shearing devices, metal processing equipment, etc., and can solve the problems of difficult high-precision product processing, precision difficult to ensure mutual cooperation, large geometric deviation, etc. problem, to achieve the effect of convenient and sensitive operation and use, small vibration, precise coordination and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

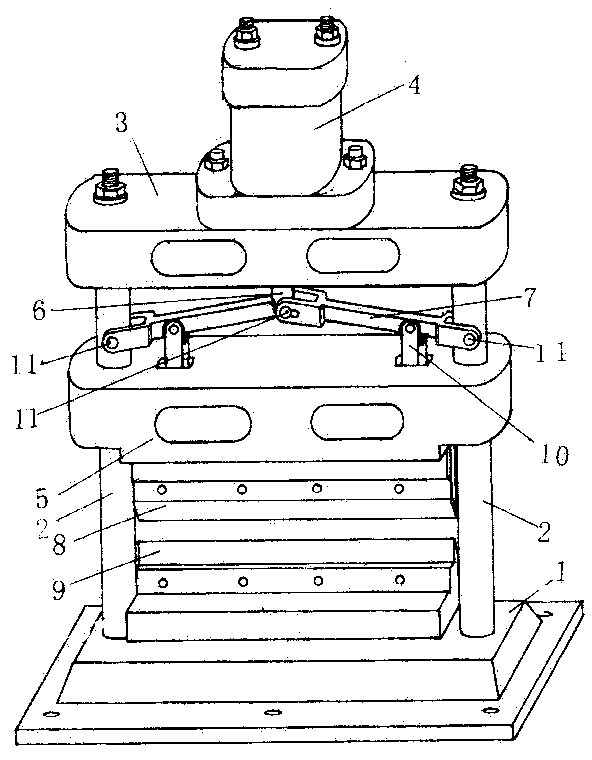

[0011] figure 1 As shown: a column 2 is arranged on both sides of a fixed base 1, and a cylinder 4 is installed on the top of the two columns 2 through a fixed beam 3, and the piston rod 6 in the cylinder 4 passes through the columns 2 on both sides. The movable beam 5 of the suit is equipped with an upper cutter 8, and the upper cutter 8 and the fixed lower cutter 9 of the base 1 constitute a corresponding shearing structure. The lower end of the piston rod 6 in the cylinder 4 is connected with the remote arm 7 fixed on the columns 2 on both sides through the pin shaft 11, and a connecting rod 10 is respectively fixed on the movable beam 5 at the remote arm 7 both sides. The remote arm 7 is connected and fixed with the uprights 2 on both sides by a pin shaft 11 .

[0012] When specifically implementing this technical solution, a guide inner sleeve should be added between the movable beam 5 and the column 2. The material of the guide inner sleeve should be the same steel as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com