Novel mullite brick and preparation method thereof

A technology of mullite brick and sintered mullite, which is applied in the field of mullite brick and its preparation, can solve the problems of insufficient high-temperature structural strength, non-wear resistance, erosion, etc., and achieve improved thermal shock stability and erosion resistance , the effect of improving high temperature structural performance and excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of mullite brick, it is prepared by aggregate, powder and anti-oxidant plus novel binding agent according to the following weight ratio and method:

[0017] Ratio: 55 parts of aggregate, including 10 parts of sintered mullite with a particle size of 0-1mm, 20 parts of sintered mullite with a particle size of 1-3mm, 25 parts of sintered mullite with a particle size of 3-5mm, and sintered mullite with a particle size of 1-3mm. The mass percentage of chemical composition is: mullite phase 80-90%, Fe 2 o 3 2 O+Na 2 O97%; 3 parts of antioxidant , the antioxidant is metal aluminum powder and metal silicon powder mixed uniformly in a weight ratio of 1 to 2:1, and its average particle size is 2 O2 >30%.

[0018] Preparation:

[0019] The first step is to mix the formula amount of aggregate evenly and add the formula amount of new binder, mix and grind for 3 minutes, then add the formula amount of powder, and continue to mix and grind for 5 minutes to obtain a semi-f...

Embodiment 2

[0026] A kind of mullite brick, it is prepared by aggregate, powder and anti-oxidant plus novel binding agent according to the following weight ratio and method:

[0027] Ratio: 55 parts of aggregate, including 15 parts of sintered mullite with a particle size of 0-1 mm, 20 parts of sintered mullite with a particle size of 1-3 mm, 20 parts of sintered mullite with a particle size of 3-5 mm, and sintered mullite with a particle size of 1-3 mm. The mass percentage of chemical composition is: mullite phase 80-90%, Fe 2 o 3 2 O+Na 2 O97%; 5 parts of antioxidant , the antioxidant is metal aluminum powder and metal silicon powder mixed uniformly in a weight ratio of 1 to 2:1, and its average particle size is 2 O2 >30%.

[0028] The preparation method is the same as in Example 1.

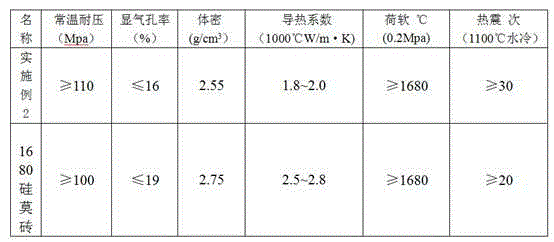

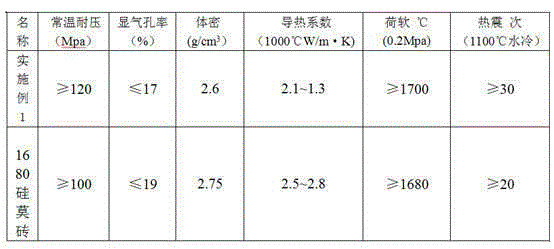

[0029] Implementation Effect:

[0030]

[0031] From above-mentioned embodiment 1, embodiment 2 can find out that each index of product of the present invention is all greater than common 1680 sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com