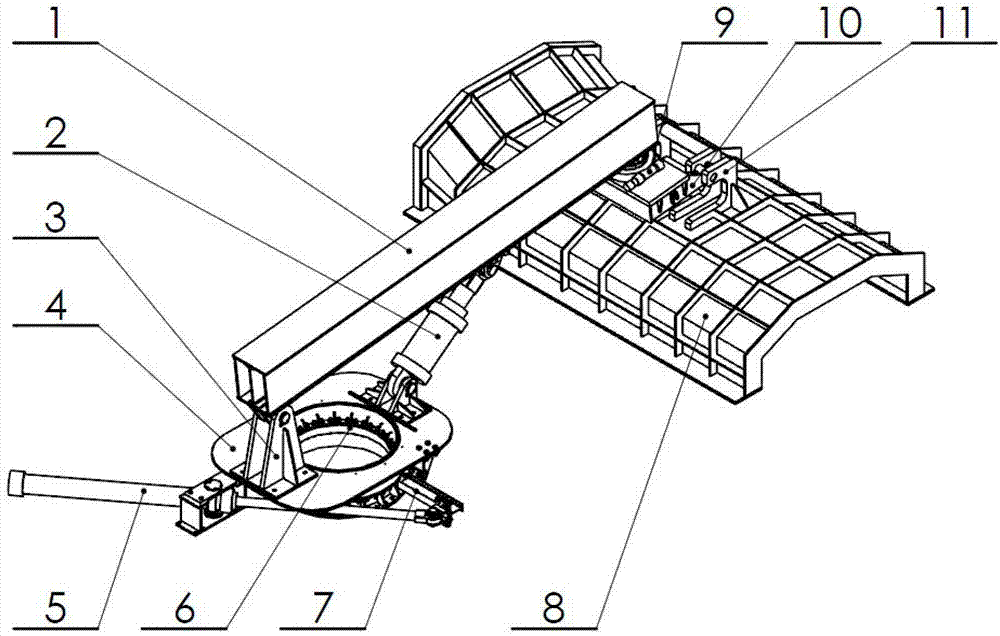

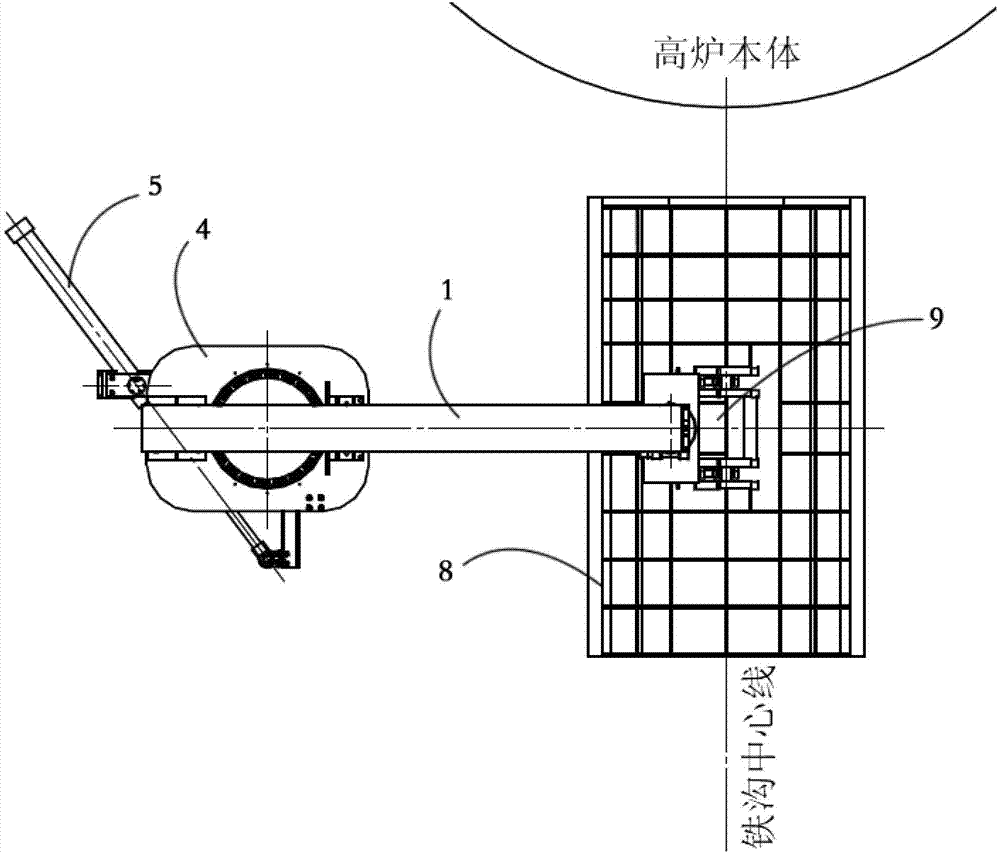

Rotary type uncovering machine and rotary type uncovering method for blast furnace iron runner

A rotary, capping machine technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of restricting the installation and use of capping machines, unable to guarantee capping and capping, and narrow space near the tap hole, etc. Achieve the effect of saving material, simple structure and reasonable overall force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

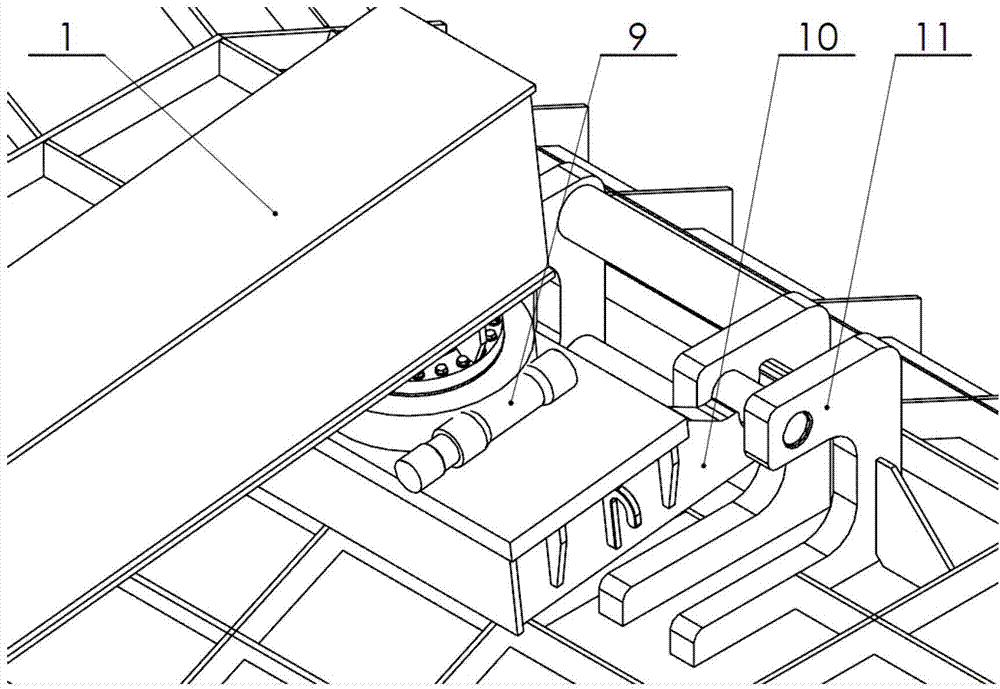

[0041] A rotary uncovering machine, used to uncover and close the ditch cover on the blast furnace iron ditch, preferably, the rotary uncovering machine includes: a rotating mechanism, a lifting mechanism, a ditch cover turning mechanism and a The suspension seat on the cover; the rotating mechanism is provided with a slewing support, and the slewing support includes two rotating parts that can rotate relatively, the first rotating part is fixed on a fixed platform, and the second rotating part is linked with a rotating drive device , and the slewing platform is fixed on the second rotating part, and the lifting mechanism is fixed on the slewing platform; the lifting structure is provided with a support, a lifting arm and a lifting drive device, and the support is fixed on the second rotating part Above, the top end of the support is hinged to the first end of the lifting arm, the first end of the lifting drive device is hinged to the slewing platform of the second rotating par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com