Suspension bridge cable bent tower beam non-support construction method

A construction method and a technology without supports, which are applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of not providing beam support structures and methods, increased construction safety risks, and long periods of support erection. The effect of increased construction cost, long construction period and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

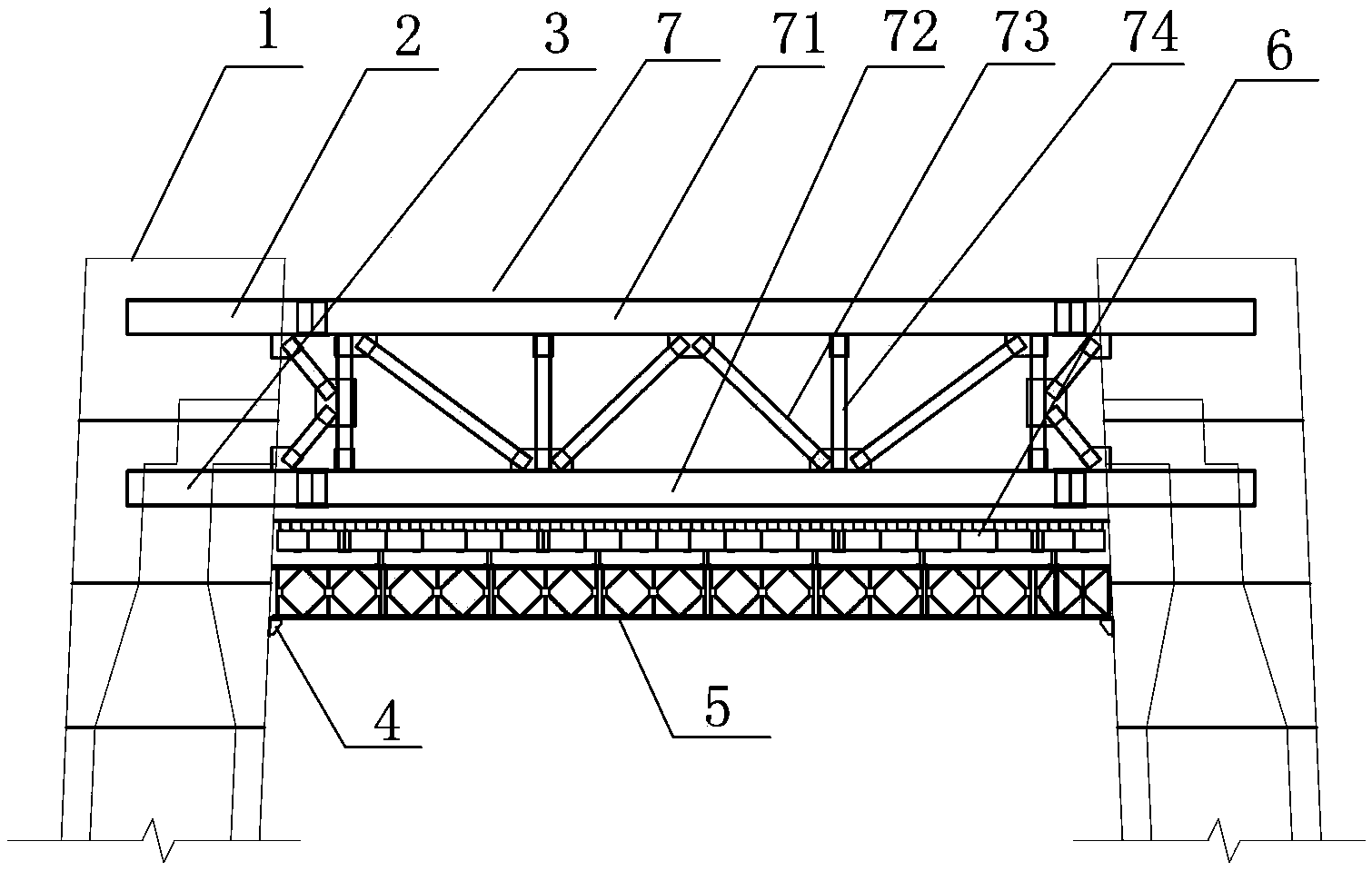

[0036] The method and construction process of the present invention will be described in detail below in conjunction with the accompanying drawings through the embodiments.

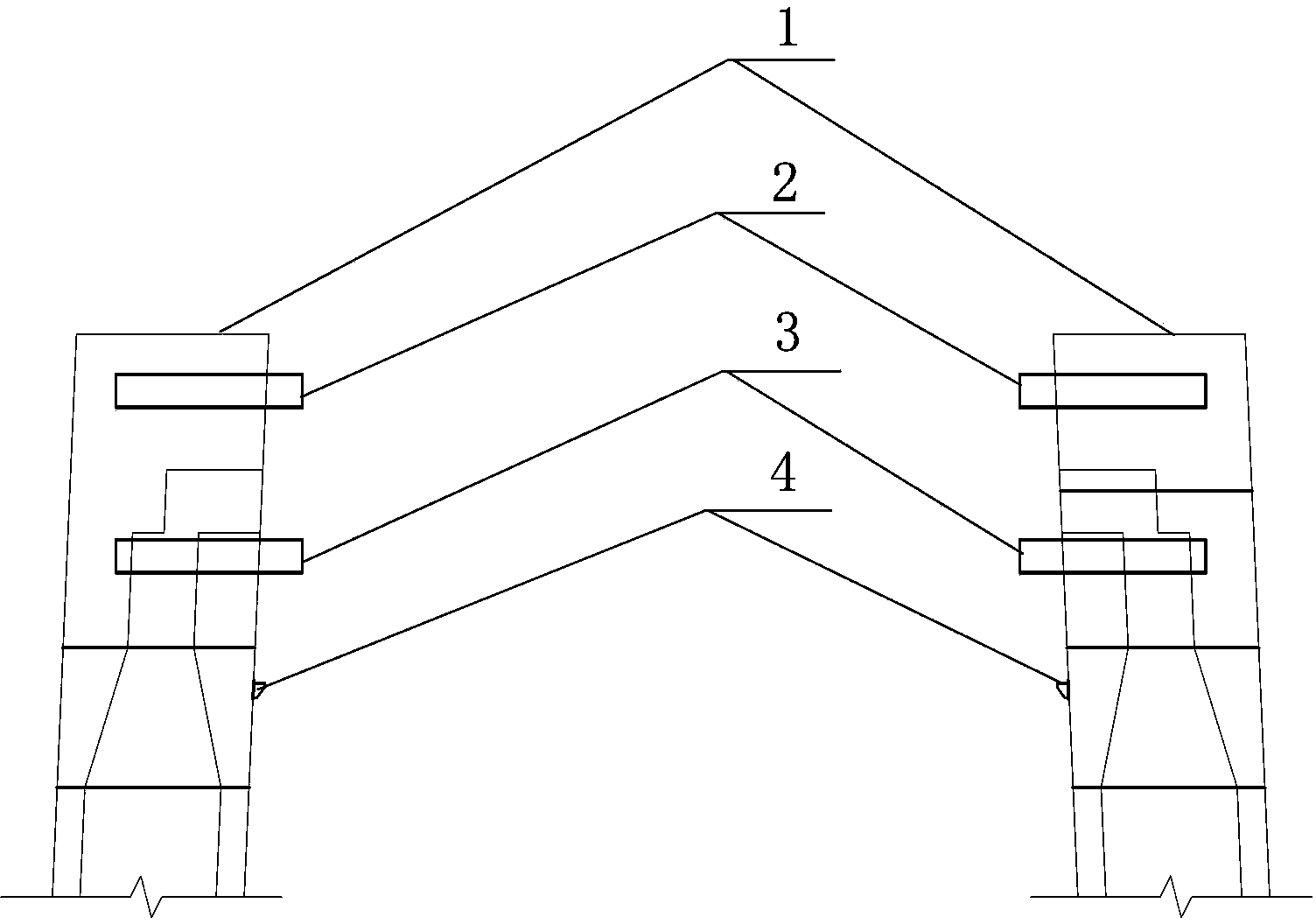

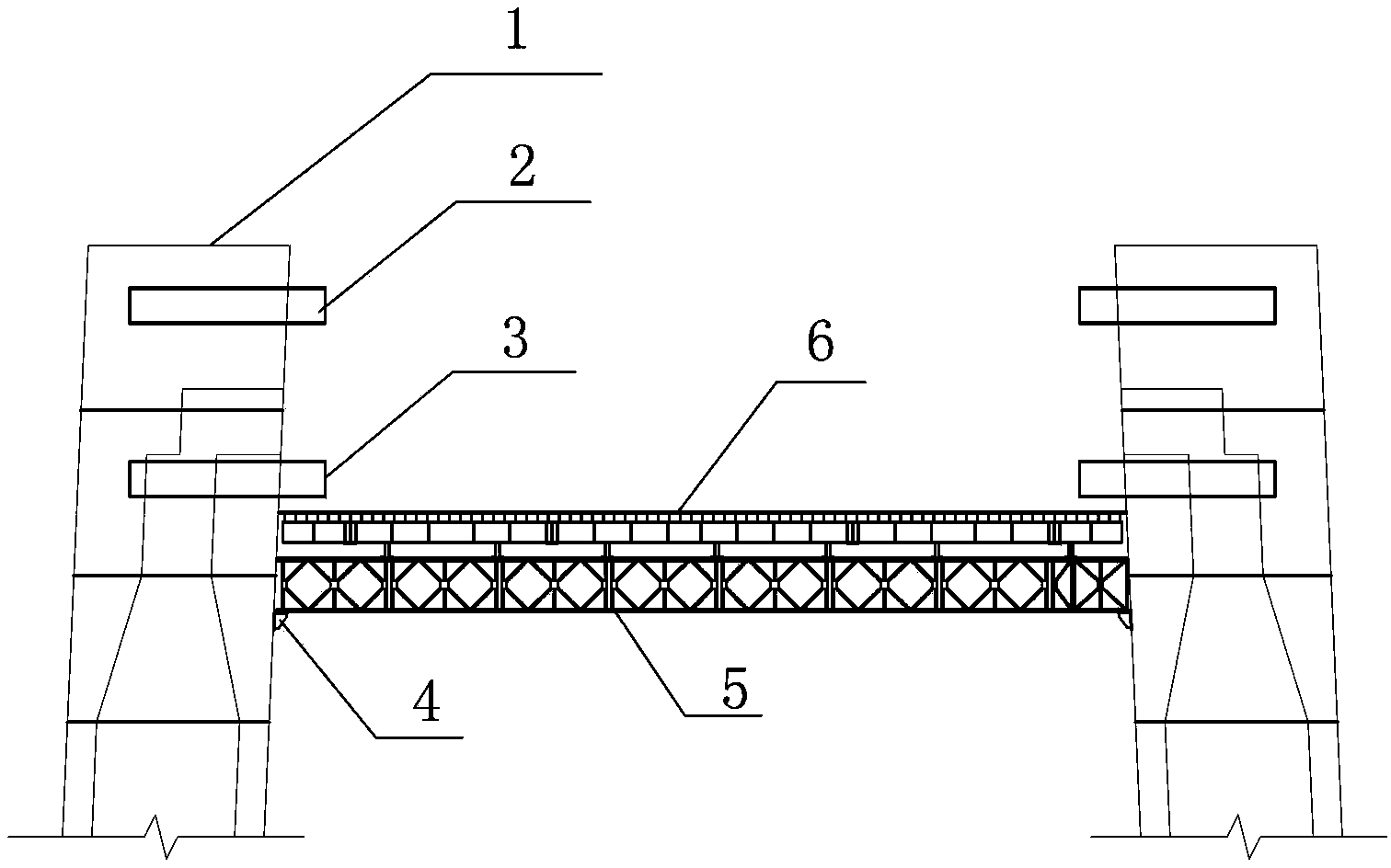

[0037] Such as figure 1 As shown, in the construction process of the tower column 1, when the tower column 1 is constructed to the predetermined position of the beam, along the opposite direction of the two tower columns, the truss connector is pre-embedded in the tower column 1, and the truss connector It includes an upper connecting piece 2 and a lower connecting piece 3, and the heights of the upper connecting piece 2 and the lower connecting piece 3 are respectively consistent with the heights of the bottom plate and the top plate of the predetermined beam; the lower connecting piece is located on the two tower columns Corbel 4 is installed below 3. According to construction requirements, it is more appropriate for the corbel 4 to be located 3-4m below the lower connector.

[0038] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com