Construction method for enabling tunnel shield to pass through vertical shaft structure

A construction method and technology of shield tunneling, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of unsatisfactory overall construction period, quality, and safety cost, and achieve strong practicability, cost saving, and work improvement. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiment of the present invention will be described in detail below by taking the shield passing through the second-lined shaft as an example.

[0036] The second lining shaft is a shaft after the shaft structure excavation is completed, and the inner wall of the shaft structure is reinforced with concrete or reinforced concrete structure. Due to the stronger concrete or reinforced concrete structure, it is more difficult for the shield to pass through the shaft wall than the tunnel part, and the tool wear is more serious.

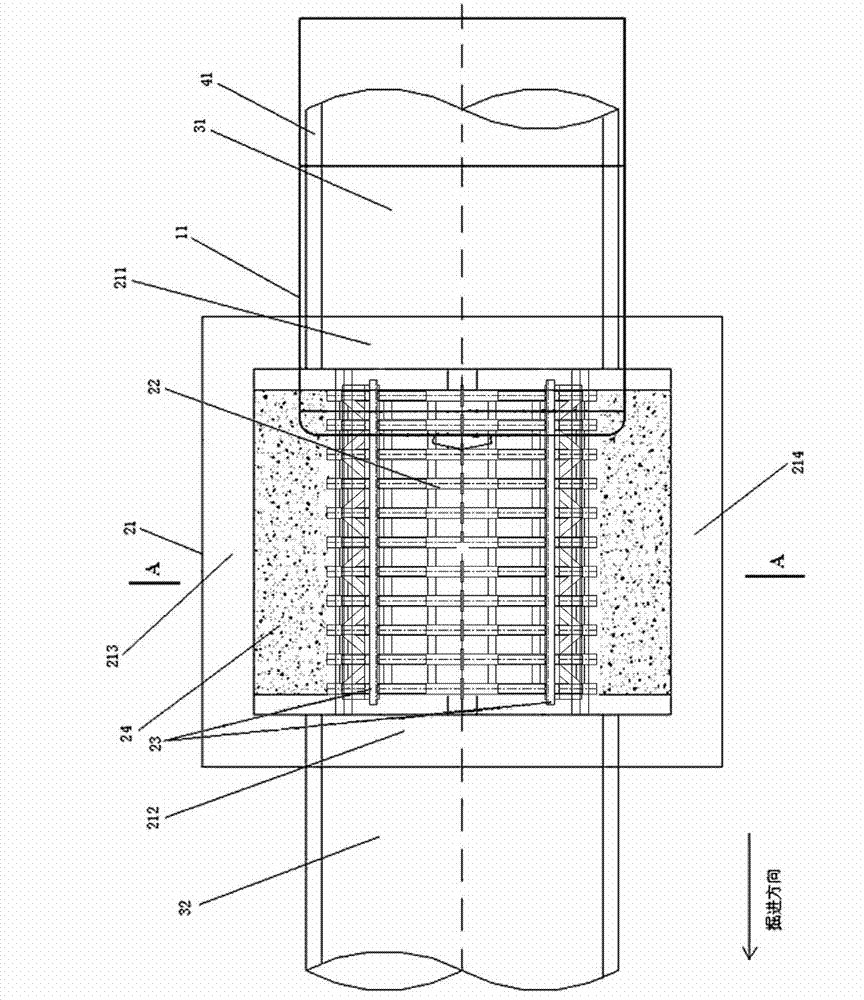

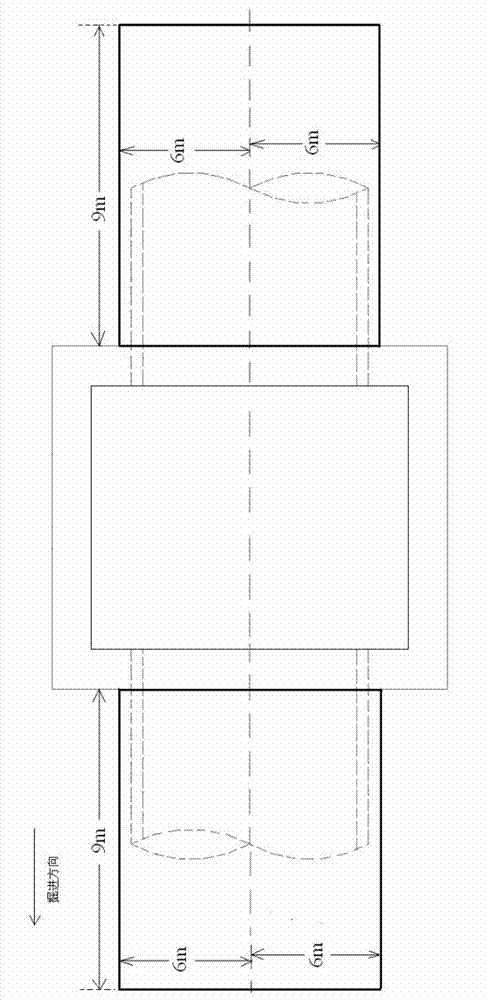

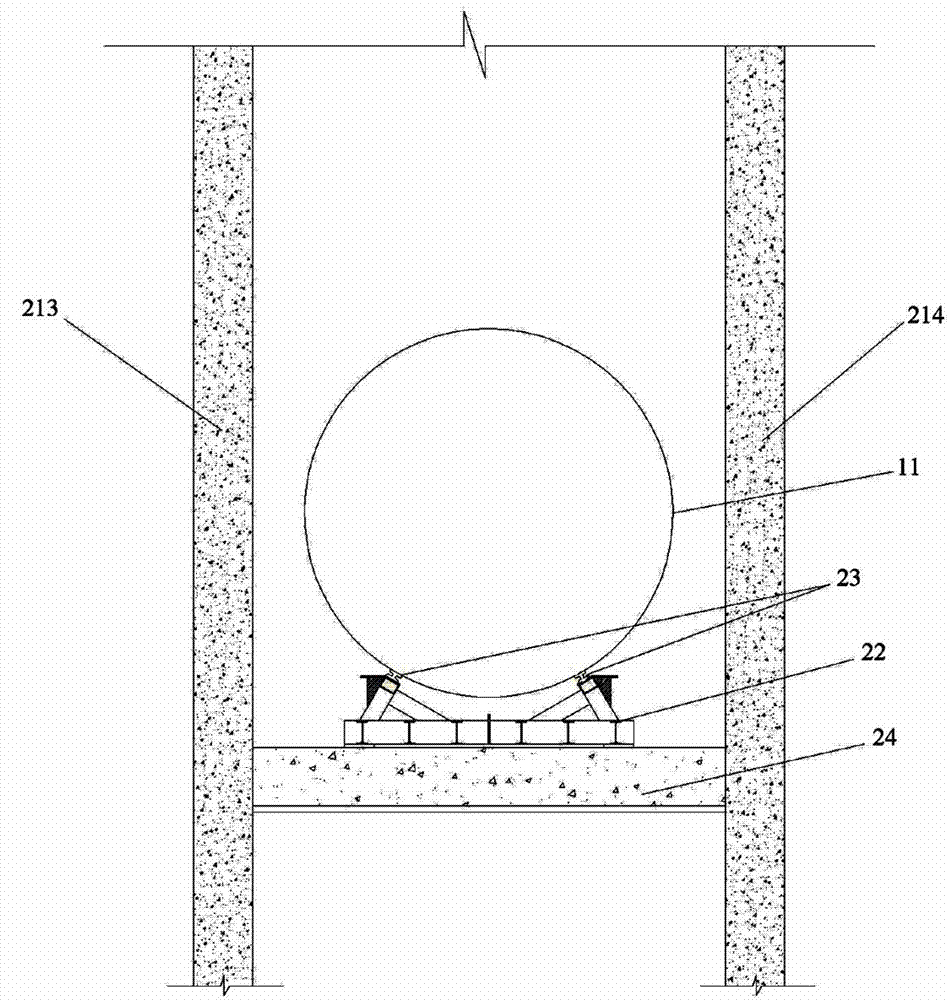

[0037] figure 1 It is a schematic top view of the shield 11 passing through the second lining shaft 21. Such as figure 1 As shown, the middle box is the well wall of the shaft, which is generally the underground diaphragm wall of concrete or reinforced concrete for the second lining shaft. The two sides of the underground diaphragm wall are where the tunnel passes. The shield tunnel 11 is excavated from the rear tunnel 31 on one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com