Novel driving system and method of main feed water pump

A technology of main feed water pump and drive system, applied in the direction of pump, machine/engine, liquid variable capacity machinery, etc., can solve the problems of complex system, increase the workload of operation and maintenance, increase equipment investment, etc., and achieve the effect of ensuring economic operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

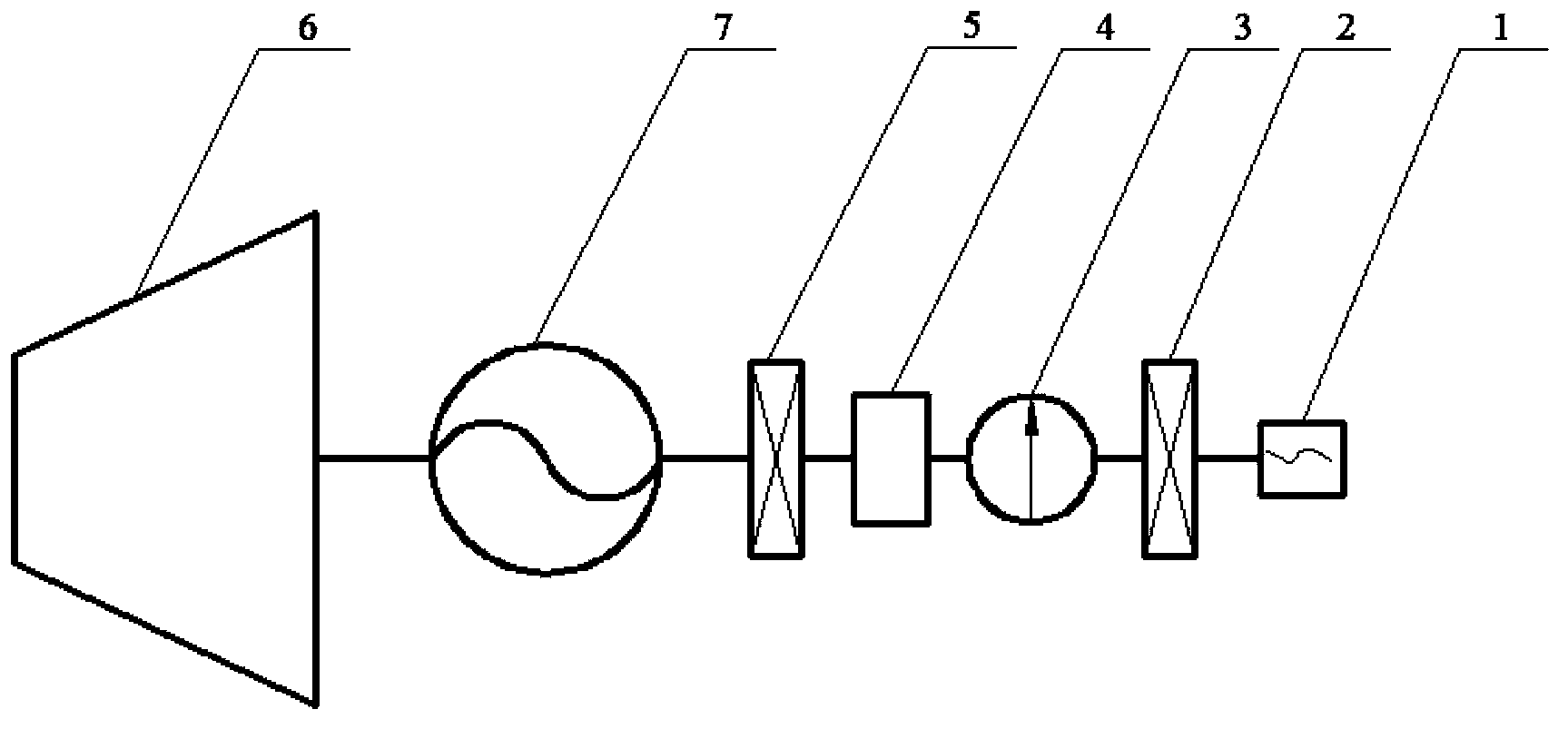

[0016] Such as figure 1 As shown, the main feedwater pump 3 and the steam turbine 6 are arranged on the same floor, the steam turbine 6 is connected to the generator 7, the main feedwater pump 3 is connected to the motor 1 through the clutch one 2, and the shaft is output at the head side of the steam turbine 6, and the clutch two 5, Speed regulating gear box 4, main feed water pump 3, clutch one 2 and electric motor 1.

Embodiment 2

[0018] Such as figure 2 As shown, the main feedwater pump 3 and the steam turbine 6 are arranged on the same floor, the steam turbine 6 is connected to the generator 7, the main feedwater pump 3 is connected to the motor 1 through the clutch 1 2, and the shaft is output at the side of the generator 7, and the clutch 2 5 is connected in sequence. Speed gearbox 4, main feed water pump 3, clutch 1 and motor 1.

[0019] During the start-up phase of the unit, the main feedwater pump 3 is driven by the motor 1 . The clutch 2 5 is separated to disengage the main feedwater pump 3 from the main shaft of the steam turbine 6. At the same time, the clutch 1 2 is combined, and the main feedwater pump 3 is driven by the motor 1 to ensure the normal operation of the main feedwater pump. This can ensure the operation of the entire main feedwater pump system Safety and reliability.

[0020] During the normal operation stage of the unit, the main feed water pump 3 is coaxial with the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com