Sealing device for pump shaft

A technology for sealing devices and pump shafts, which is applied to components, pumps, and pump elements of pumping devices for elastic fluids, which can solve problems such as leakage, and achieve the effects of avoiding pollution, ensuring safety, and facilitating safe transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

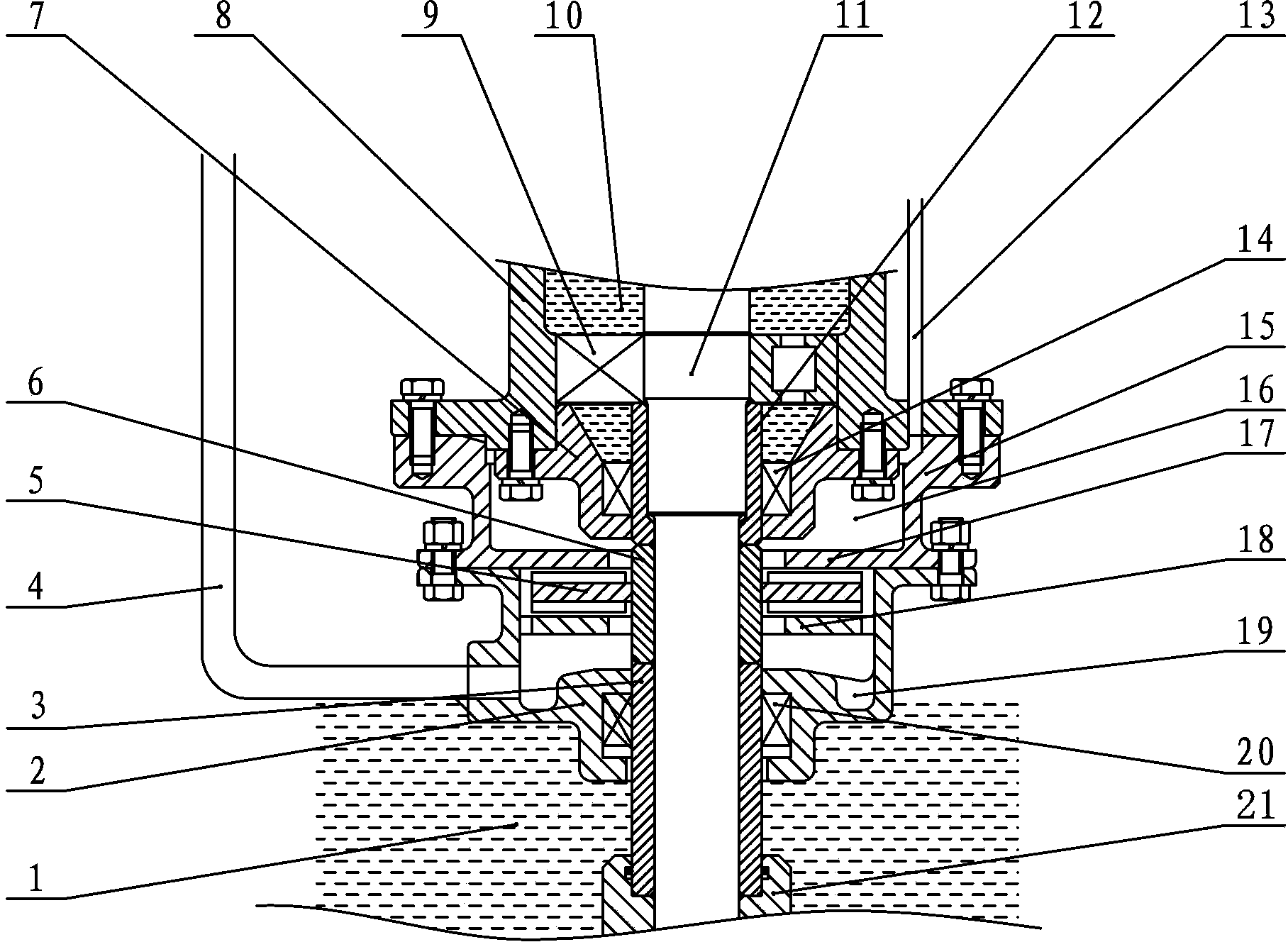

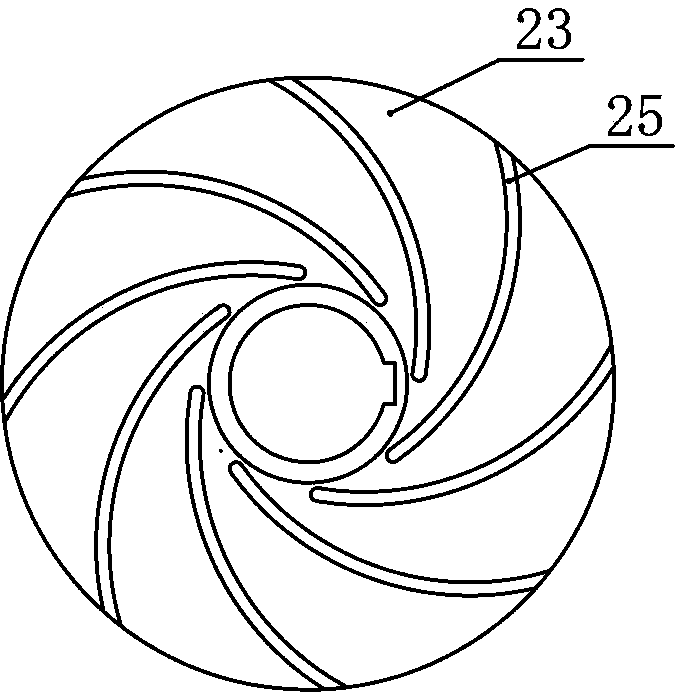

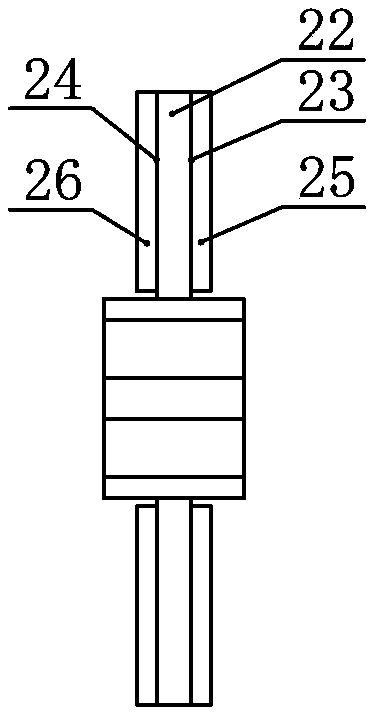

[0032] like figure 1, as shown in 2, 3, 4, 5, 6, and 7, a pump shaft sealing device includes a lubrication side sealing system installed on the main shaft 11 away from the end of the pump head 21, and a material side installed on the main shaft 11 near the end of the pump head 21 Sealing system, the lubrication side sealing system includes the first sealing seat 7 and the first seal 14 installed on the first sealing seat 7, the material side sealing system includes the second sealing seat 2 and the first sealing seat 2 installed on the second sealing seat 2 Two seals 20. In this embodiment, both the lubricating side sealing system and the material side sealing system adopt the mechanical seal method, because the mechanical seal has high reliability and long service life, which meets the high reliability requirements of the sealing device, and the mechanical seal can reduce the sealing cost. The cost of the device. The lubricating side sealing system and the material side seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com