System for eliminating ice block of supercooled water ice-making apparatus by using heat of condensation

A technology for supercooled water and refrigeration systems, applied in ice making, ice making, applications, etc., can solve the problems of lack of deicing blocking methods, large investment, complex systems, etc. The effect of energy consumption and total reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

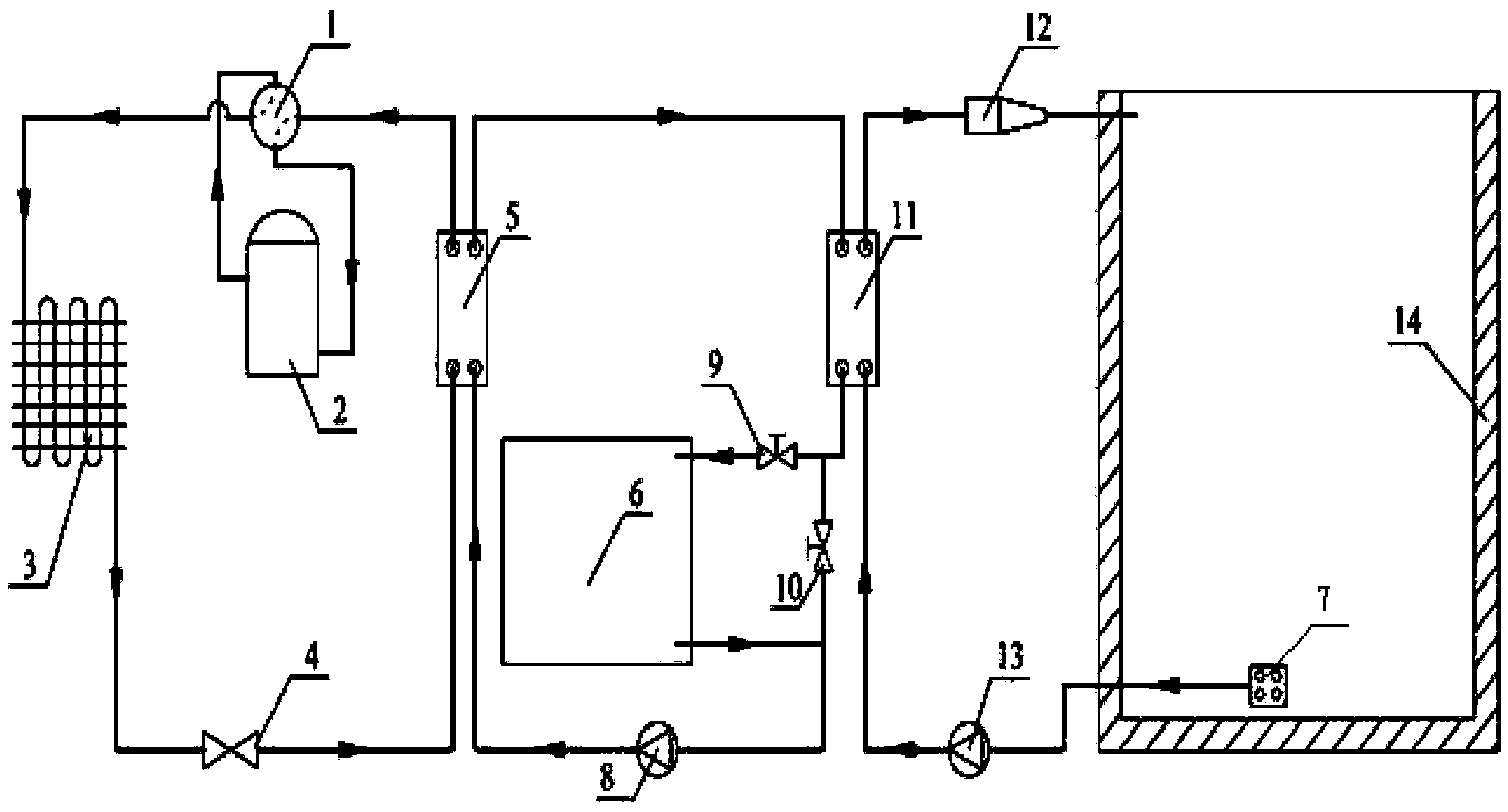

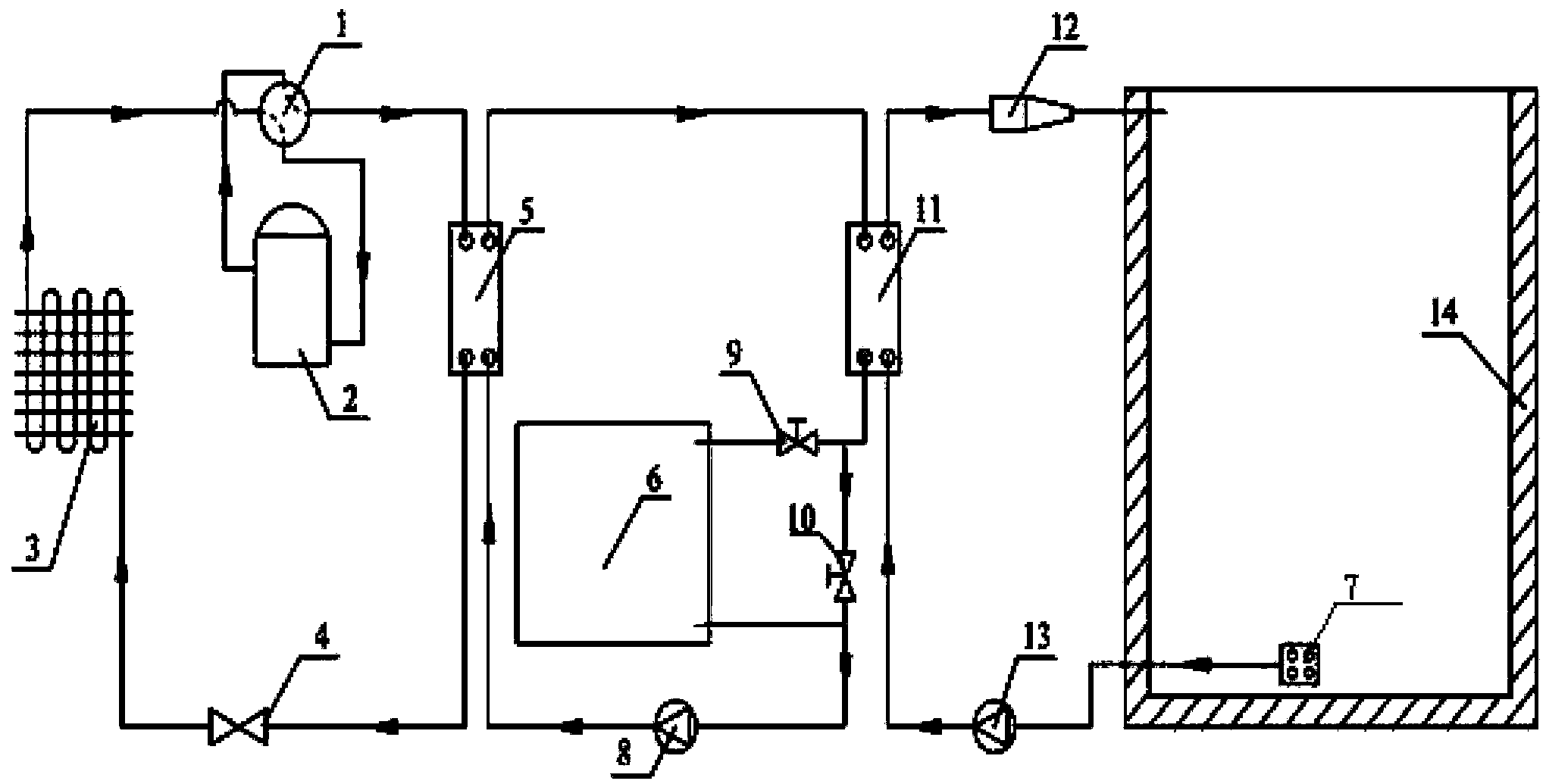

[0017] as attached figure 1 - As shown in -2, a kind of deicing blocking system of a supercooled water ice making device utilizing condensation heat of the present invention includes a compressor 2, a four-way reversing valve 1, a heat exchanger 3, a throttling device 4 and a first plate type Refrigeration system composed of heat exchanger 5; composed of first circulating pump 8, first plate heat exchanger 5, second plate heat exchanger 11, first shut-off valve 9, brine tank 6 and second shut-off valve 10 The brine system; the subcooled water system composed of the second plate heat exchanger 11, the subcooling remover 12, the ice storage tank 14, the first filter 7 and the second circulation pump 13. The connection structure of the system is: the refrigeration system is connected to the brine system through the first plate heat exchanger 5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com