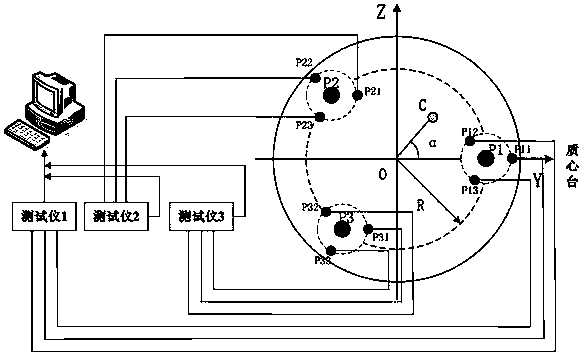

3*3 type three-point dynamometric center-of-mass table system

A platform system and center of mass technology, applied in the field of spacecraft assembly testing, can solve problems such as errors, mistakes, and deformation of the center of mass table, and achieve the effect of meeting the measurement needs, high precision, and expanding the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

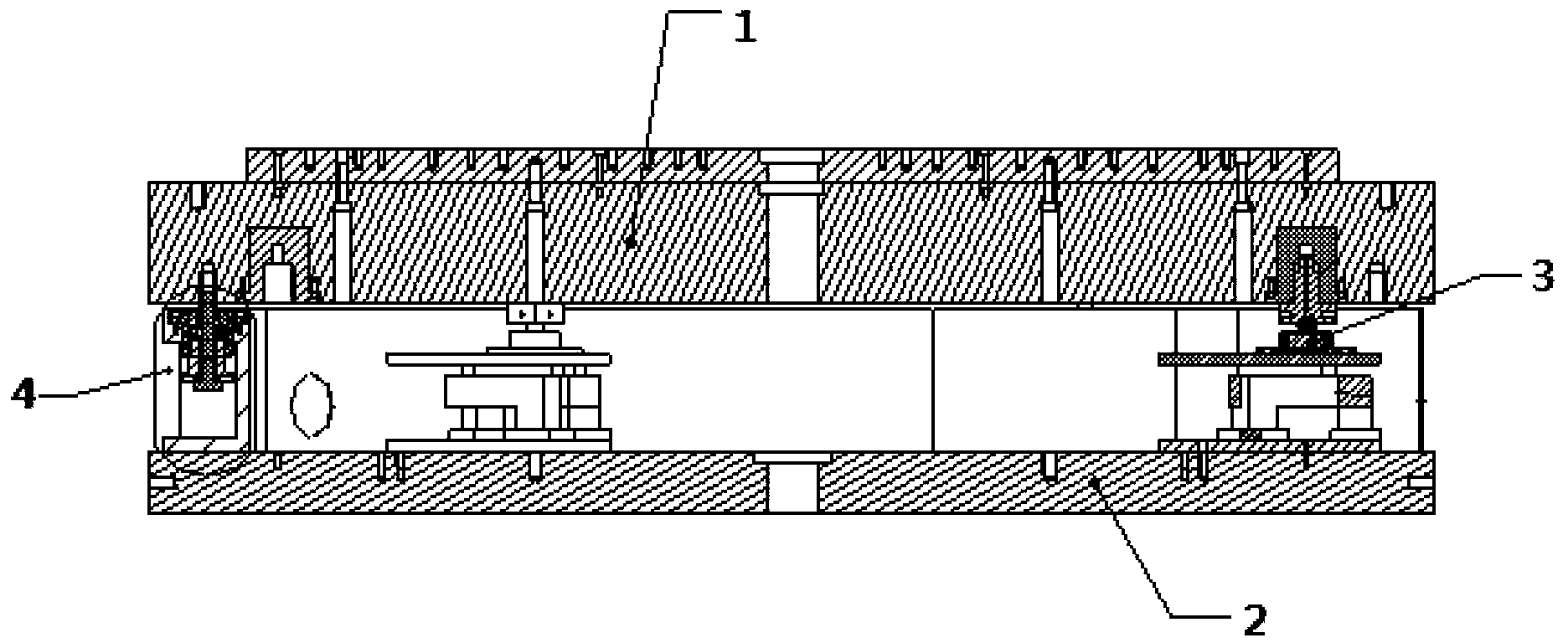

[0018] The 3x3 type three-point force centroid platform system of the present invention will be described in detail below with reference to the accompanying drawings, but the description is only exemplary and not intended to limit the protection scope of the present invention.

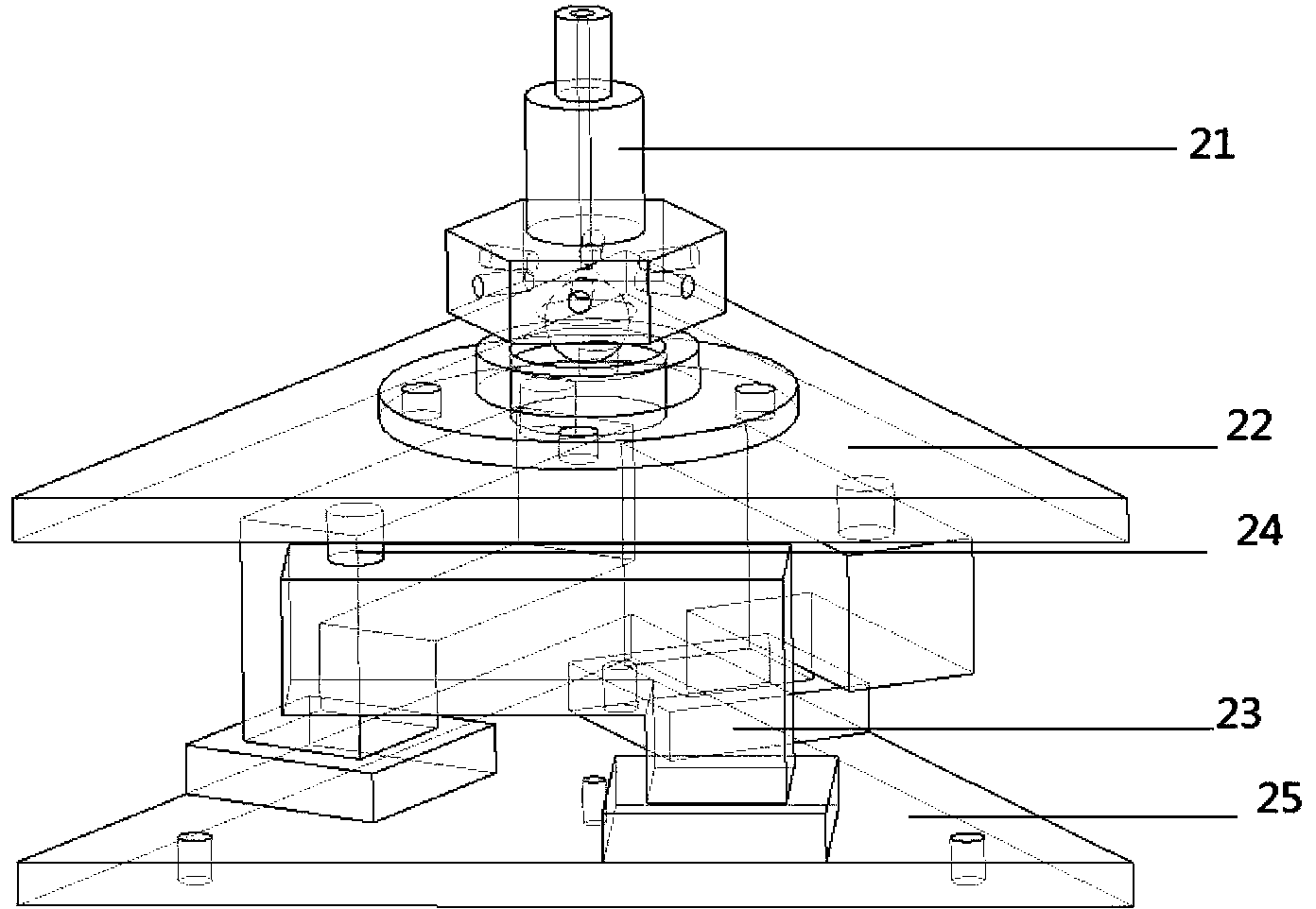

[0019] refer to figure 1 , figure 1 The 3 by 3 type three-point force-measuring center-of-mass platform system of the present invention is exemplarily illustrated. The force-measuring center of mass platform includes an upper table 1, a sensor assembly 3, an auxiliary support 4 and a lower table 2. The structure of the upper table 1 is a steel-aluminum composite table. The steel table provides the connection interface between the test piece and its upper surface, and the aluminum table below it. , to accurately transfer the weight of the loaded test piece to the three sensor assemblies distributed at an angle of 120o on the same circumference. The sensor assembly 3 accurately transfers the weight to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com