Multi-station automatic detection apparatus for electronic products

An automatic detection and electronic product technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as operator fatigue, safety hazards, product quality, and waste of manpower, and achieve low labor intensity, save manpower, The effect of liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail in conjunction with the accompanying drawings and specific embodiments.

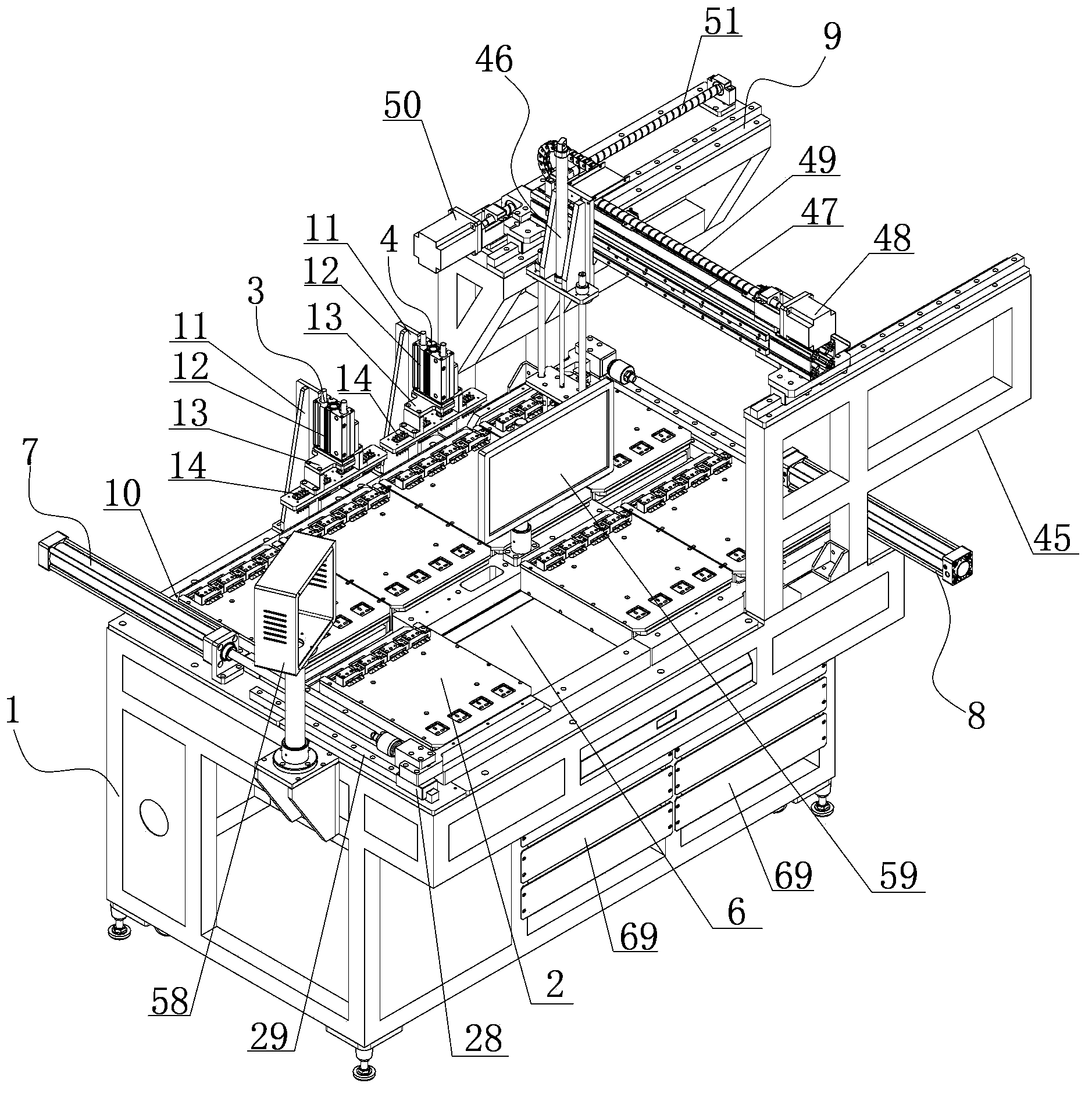

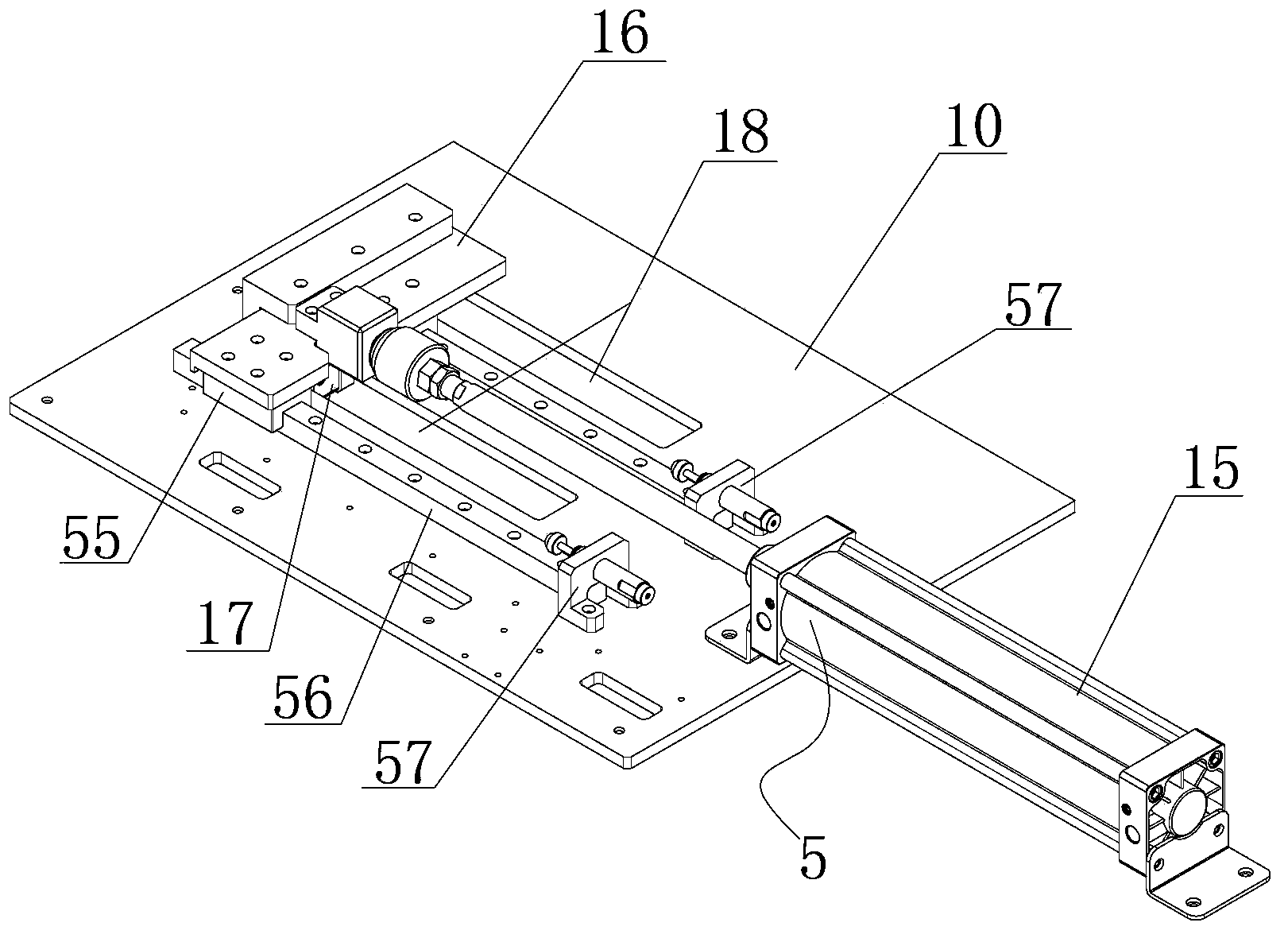

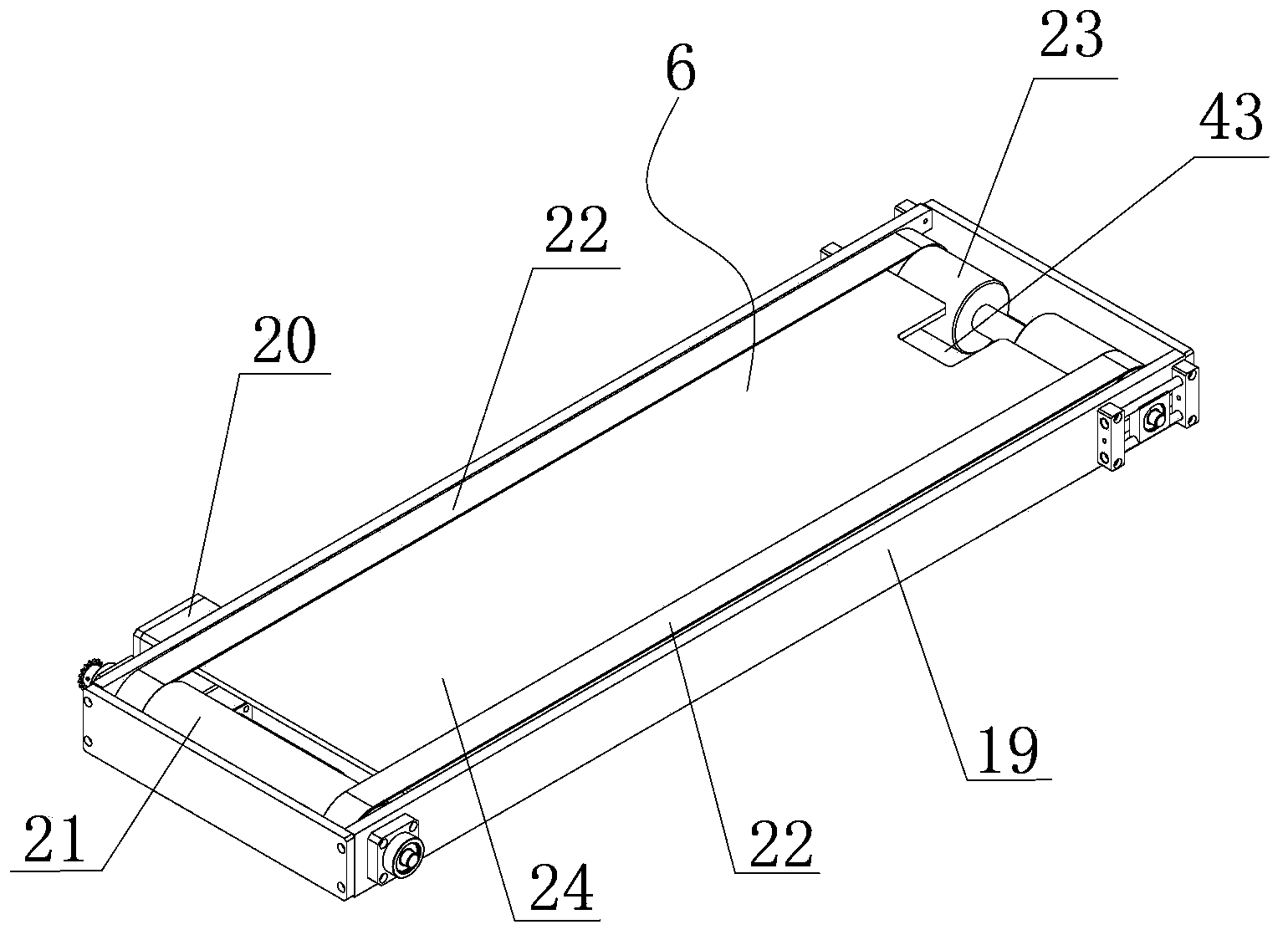

[0040] Provide a multi-station automatic detection equipment for electronic products, such as figure 1 As shown, it includes a frame 1 with a charging mechanism connected to the rear end. The frame 1 is provided with a plurality of stations for placing fixtures. 2. The safety inspection mechanism 3 and the function inspection mechanism 4 installed on the left end of the frame 1, the fixture translation mechanism 5 installed on the back of the test platform 10 on the left part of the frame 1, the fixture circulation mechanism 6 installed on the right part of the frame 1, The fixture left-moving mechanism 7 and the fixture right-moving mechanism 8 respectively installed at the front and rear ends of the frame 1; a control panel 58 for controlling the operation of the automatic detection equipment and a display 59 for reflecting detection information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com