Thermostatic mixing valve with integrated flow diverter

A technology of mixing valve and flow divider, which is applied to control the mixing ratio of fluids at different temperatures, instruments, valve details, etc. It can solve the problems of inconvenient use, large valve volume, and unreliability, and achieve easy movement, small volume, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

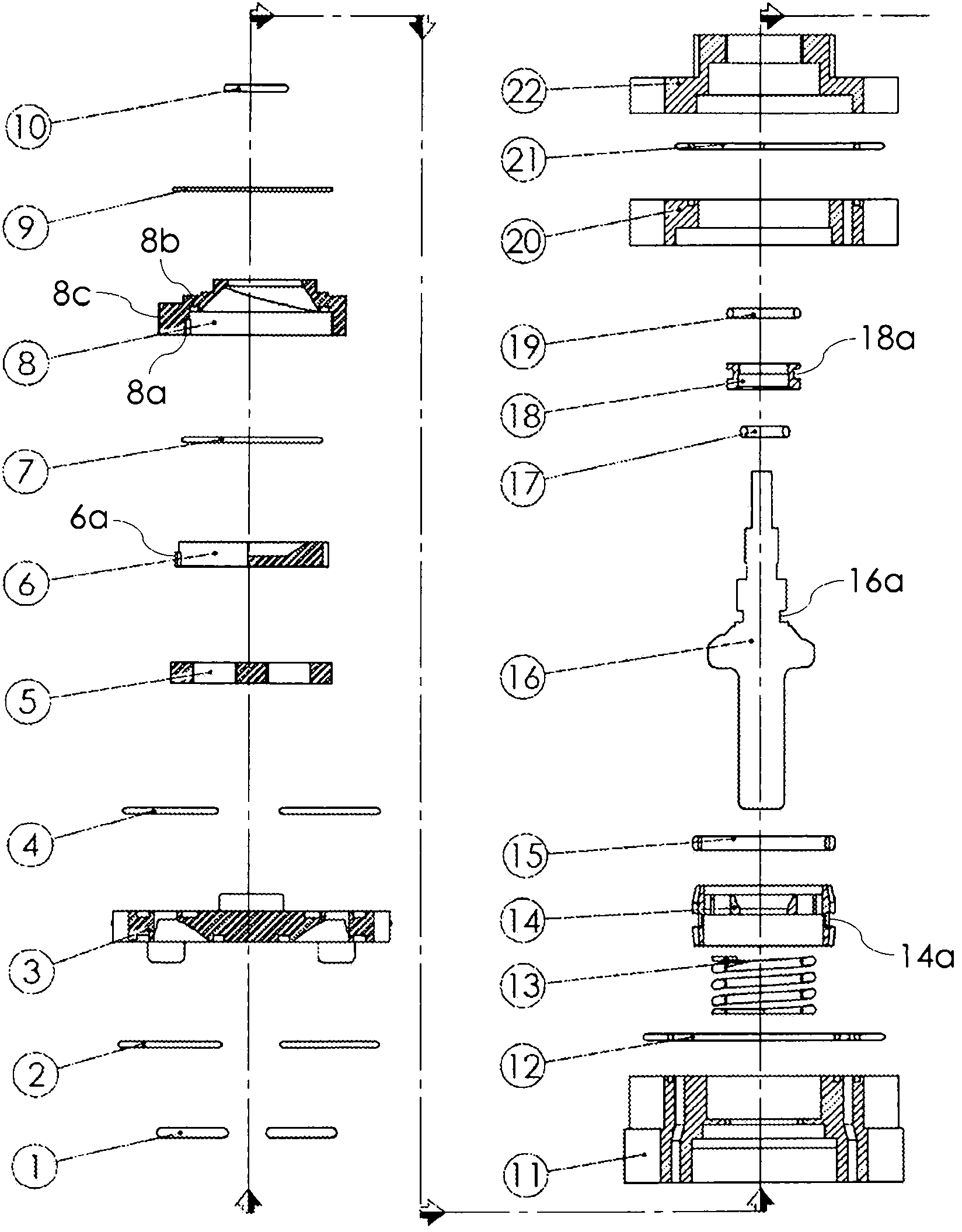

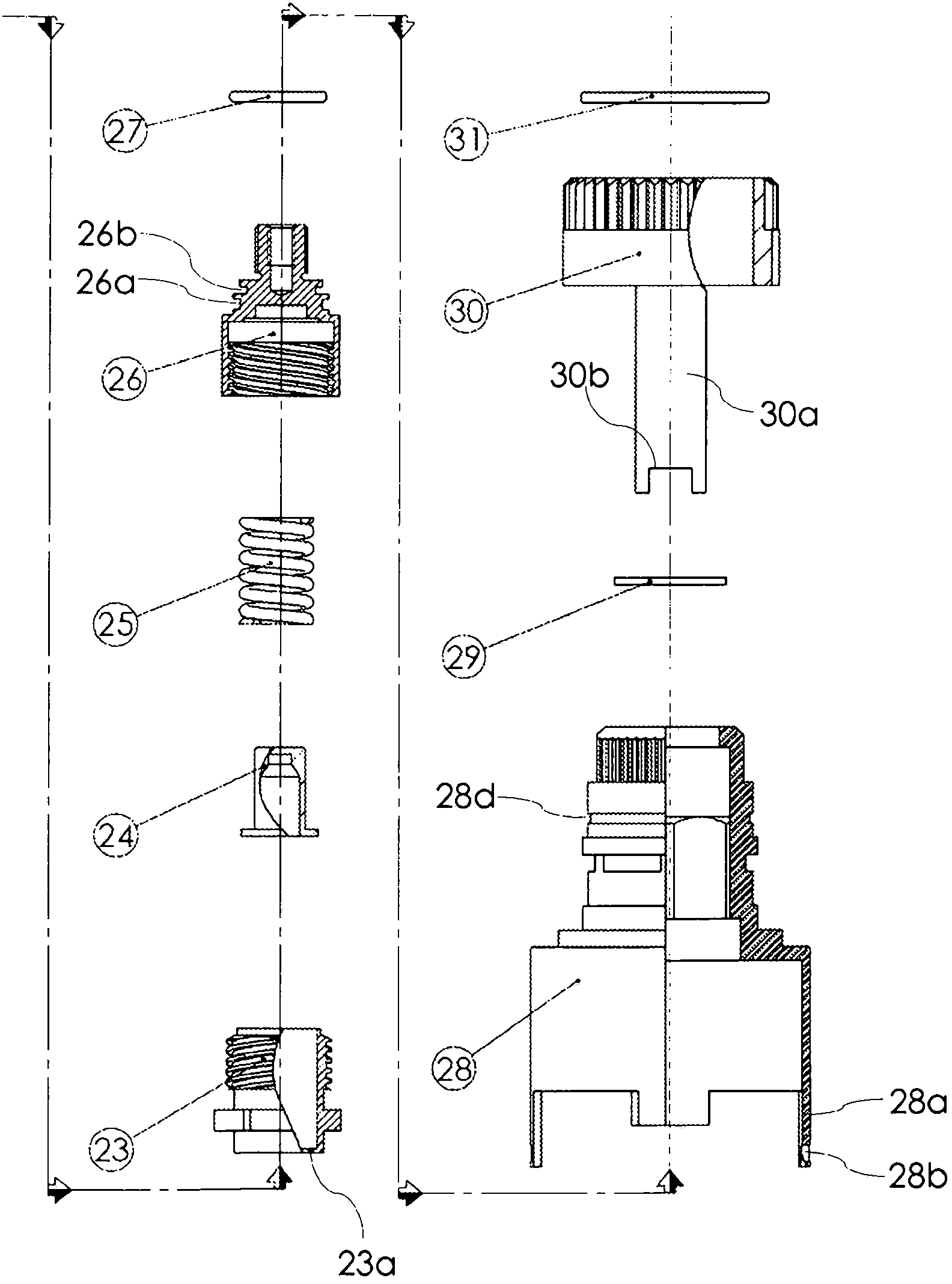

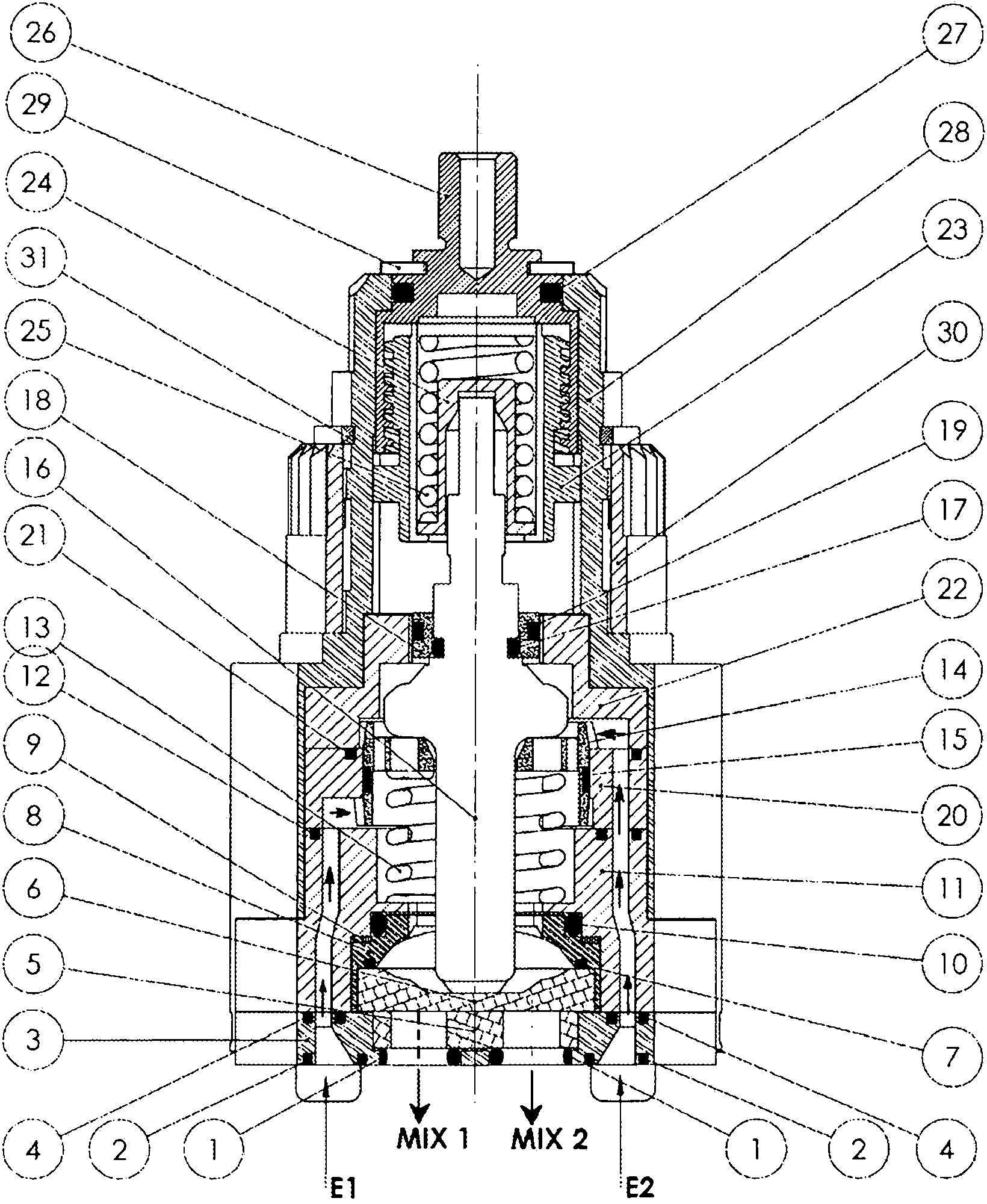

[0026] Referring to Figures 1-3, it can be seen that the valve of the present invention comprises a valve block, described in detail later, housed partly in the base 3 and partly in the cylinder 11, which is extended downwardly from the housing 28. At least one pair of tab portions 28a are closed with the housing 28 fixed to the base 3, said tab portions 28a having openings 28b which engage corresponding locking teeth formed on the outer side of the base 3. In this way, according to the first novel aspect of the invention, the cylindrical body 11 is closed by the casing 28 and achieves a watertight seal with the base 3 .

[0027] Formed in the base 3 are two outermost openings E1 and E2 for inflow of hot and cold water respectively, and two innermost openings MIX1 and MIX2 for outflow towards two different users such as a shower head or a hand shower mixed with water. On the bottom side of the base 3, a seat is formed for accommodating a gasket achieving a watertight seal, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com