Laser axis calibrating method and laser processing device utilizing the same

A calibration method and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as optical axis deviation, achieve the effect of reducing calculation load and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Next, an embodiment of the present invention will be described with reference to the drawings.

[0086]

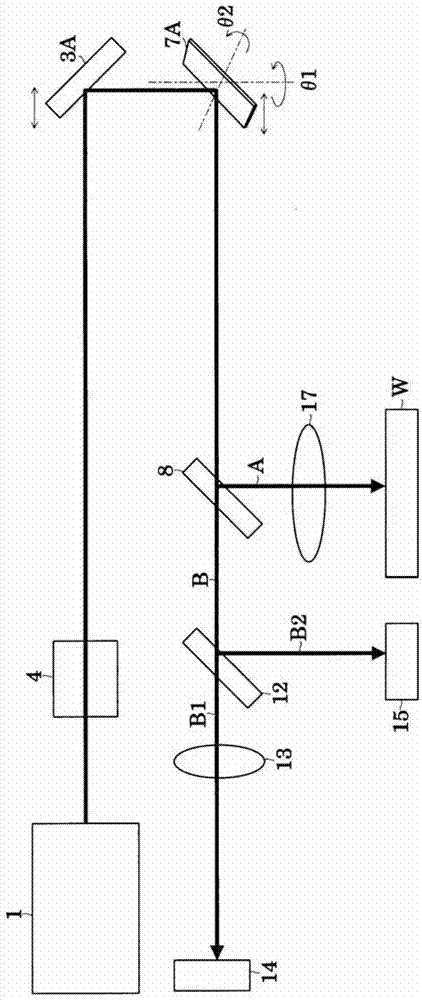

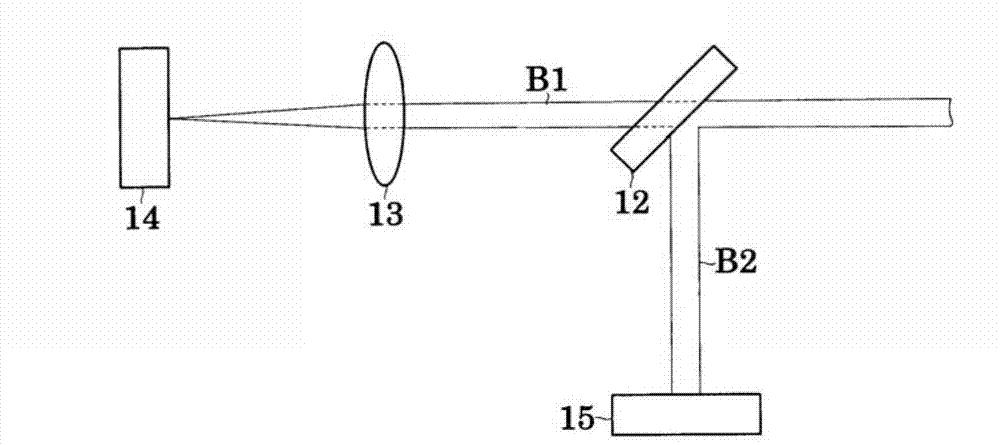

[0087] figure 1 A figure illustrating the principle of the laser optical axis calibration method of the present invention; figure 2 An enlarged view of the surrounding area of the 2D semiconductor detector.

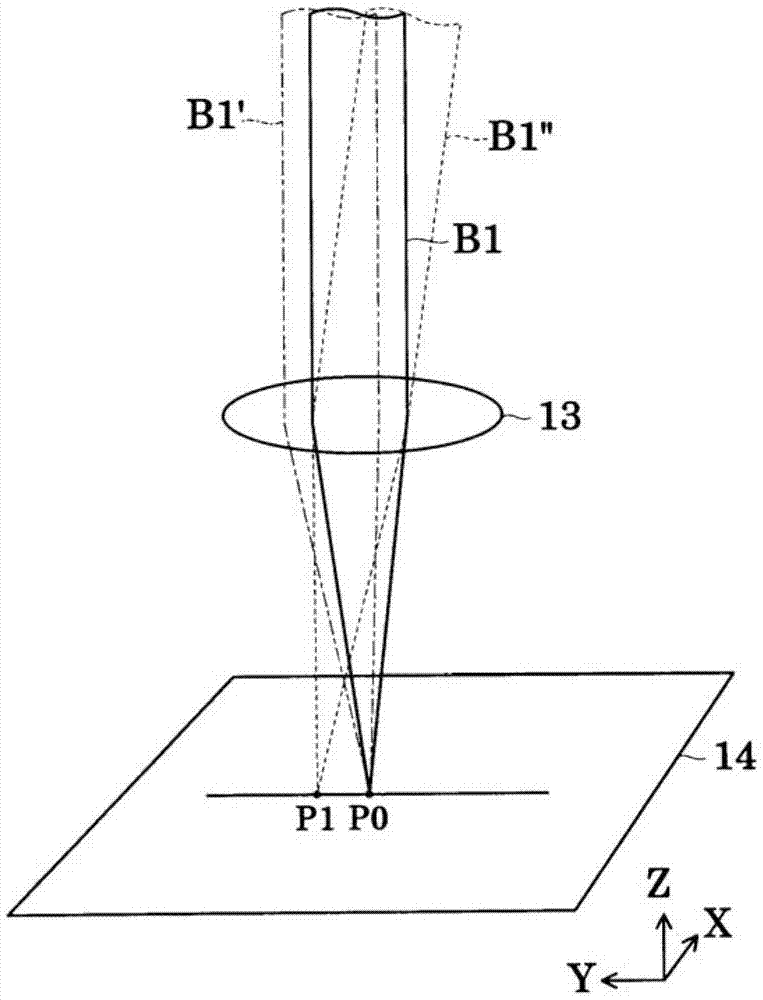

[0088] Such as figure 1 with figure 2 As shown, a beam expander 4 , a first mirror 3A, a second mirror 7A, a beam sampler 8 and a condenser lens 17 are disposed between the laser oscillator 1 and the workpiece W. In addition, a beam splitter 12 , a condensing lens 13 , and a two-dimensional semiconductor position detector 14 are disposed on the optical path of another laser beam B branched by the beam sampler 8 (hereinafter referred to as “measurement light B”). Here, the laser beam directed from the beam splitter 12 to the two-dimensional semiconductor position detector 14 serves as measurement light B1. Further, a two-dimensional semiconductor posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com