Novel polyolefin pipe-based basket type machine head

A polyolefin and die technology, which is applied in the field of polyolefin pipe basket die, achieves the effects of wide application range, long service life and increased extrusion volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

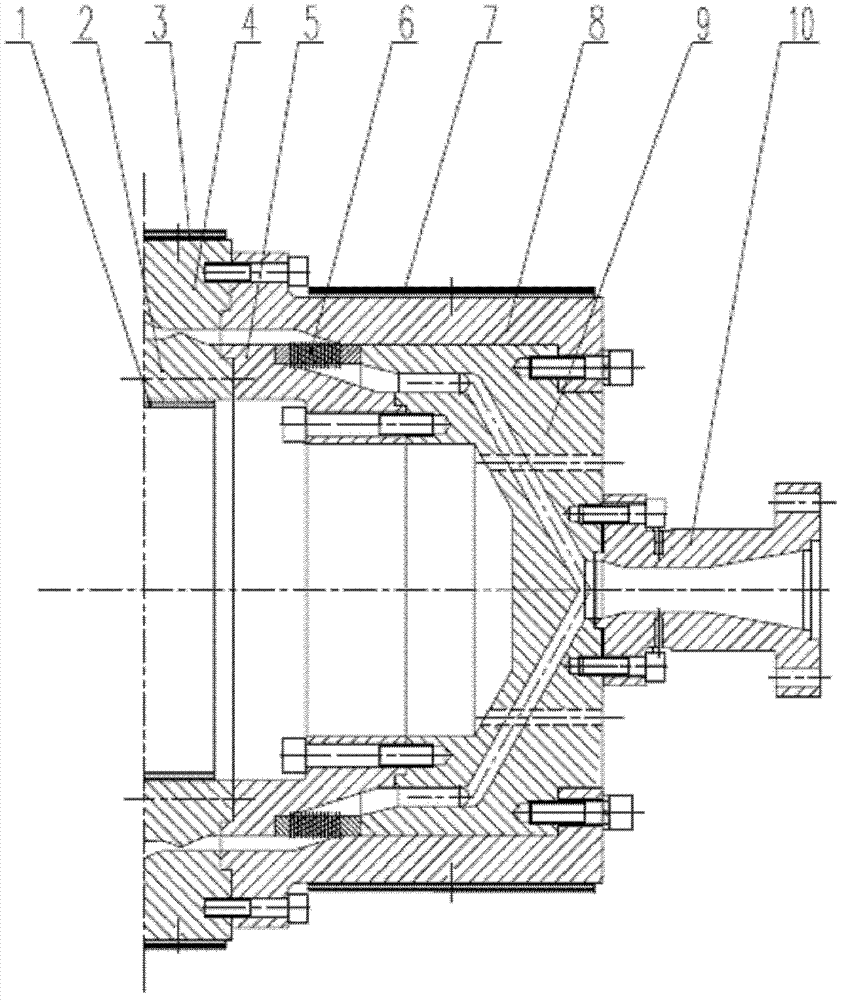

[0025] A new type of polyolefin pipe basket head, its structure is as follows figure 1 As shown, it includes a first heater 1, a second mold core 2, a second heater 3, a second mold cavity 4, a first mold core 5, a screen basket 6, a third heater 7, a first mold cavity 8 and Phantom 9. The mold body 9, the first mold cavity 8 and the second mold cavity 4 are sequentially connected to form the shell of the machine head. The first mold core 5 and the second mold core 2 are sequentially connected to form an inner core. The inner core is located in the above-mentioned shell and forms a melt flow path with the shell. The melt flow path is made of surface-hardened and quenched and tempered chromium. Made of alloy steel. A second heater 3 and a third heater 7 are arranged on the outer surface of the mold cavity. The second mold core 2 is a hollow core mold, and a first heater 1 is arranged on its inner wall. The second mold core 2 is connected with the first mold core 5 and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com