A fuel filler molding method and preparation device used in two-piece blow molding process

A molding method and blow molding technology, applied in the field of fuel tank blow molding manufacturing, can solve the problems of increased evaporative emissions of hydrocarbons, difficulties in meeting emission regulations, and high costs, and achieve low cost, reduced cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

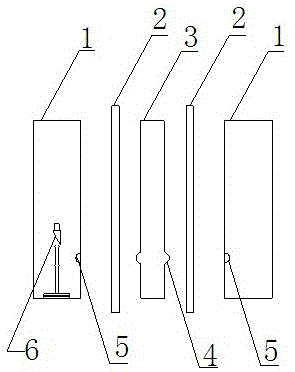

[0035] see figure 1 — Figure 6 , in order to achieve the above object, the technical scheme of the present invention is as follows, a fuel filler filler molding method applied in the two-piece blow molding process, the molding method includes the following steps, see figure 1 ,

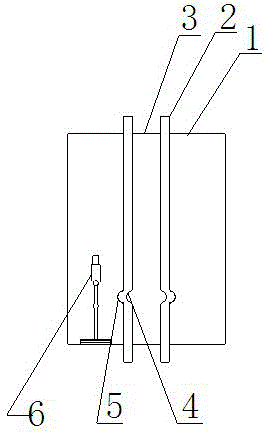

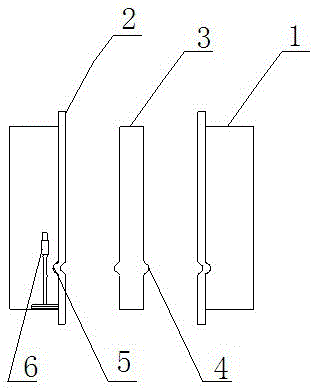

[0036] 1) Feeding, this step is mainly two pieces, the molten parison is respectively fed into the two gaps formed by the preform template 3 and the two mold halves 1; see figure 2 , 2) The mold half 1 is closed with the preform template 3; 3) High pressure blow molding; see image 3 , 4) Mold 1 opens and preform template 3 exits; see Figure 4 , 5) The fuel filler extrusion molding device moves in; see Figure 5, 6) The mold half-mold 1 is closed again; 7) High-pressure blow molding, and the fuel filler is extruded; 8) The fuel filler extrusion molding device is moved out;

[0037] 9) The mold is fully opened again; 10) The product is taken out.

[0038] The main feature of this method is tha...

Embodiment 2

[0039] Embodiment 2: As a further improvement of the present invention, a cooling device is provided on the fuel filler extrusion molding device in the step 5. The cooling device adopts cooling water, and the cooling device enables sufficient cooling of the fuel filler structure and has sufficient strength to prevent deformation in the later stage. All the other results and advantages are exactly the same as in Example 1.

Embodiment 3

[0040] Embodiment 3: see figure 1 , as a further improvement of the present invention, in the step 2, the preform template 3 is provided with a protrusion 4, and the number of the protrusion 4 is two, which are symmetrically arranged on both sides of the preform template 3, and the mold The mold half 1 is provided with a groove 5 corresponding to the protrusion 4 . There is a protruding structure at the filling port of the fuel tank corresponding to the preform template 3 device, and a groove structure is provided on the mold. After closing with the mold, the external shape of the filling port is formed when the structure is closed by the protrusion and the groove. The molding method is different from blow molding. It uses the blank of the fuel tank to form the external shape of the fuel filler while performing the preformed seal. After this process, the external structure of the fuel filler is formed in half on the left and right sides of the fuel filler. . All the other re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com