Manufacture method of metal compound flexible graphite gasket

A technology of flexible graphite and manufacturing methods, applied in the direction of metal layered products, chemical instruments and methods, lamination devices, etc., can solve problems such as leakage, large pre-tightening force, and easy damage to the sealing surface, and achieve simple process and high resilience High, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The manufacturing method of the metal composite flexible graphite gasket is according to the following steps:

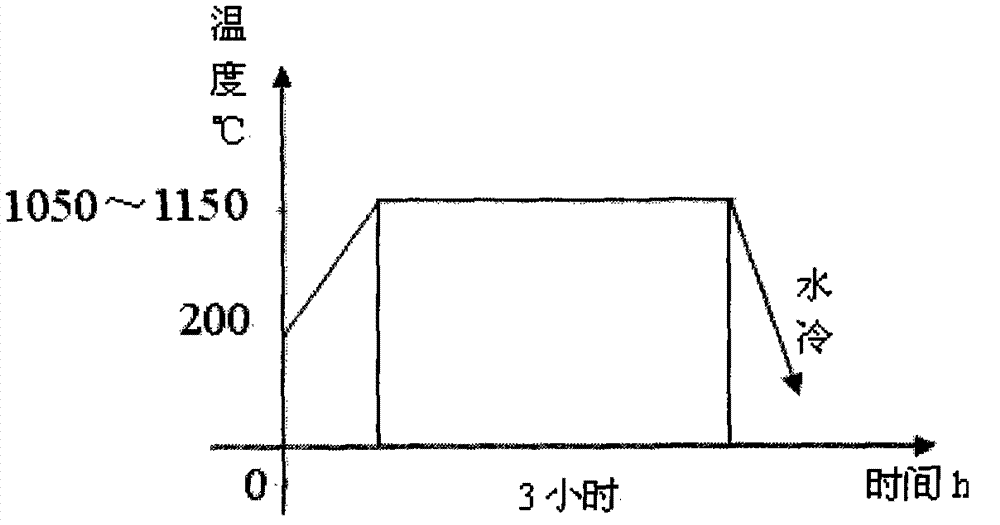

[0036] a. Preheat the metal material at a temperature ≤ 200°C, put it into a heating furnace and raise the temperature to 1050-1150°C, and keep the temperature constant for 3 hours;

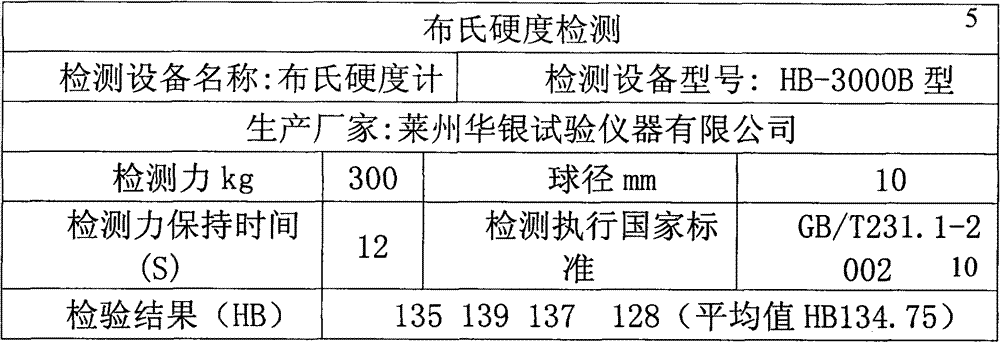

[0037] b Then take the metal material out of the heating furnace and quickly put it into cooling water to cool down; after the above heat treatment process, the hardness of the metal material is reduced, and the tested performance parameters are shown in Table 1; figure 2 is the aging heat treatment curve of its metal material;

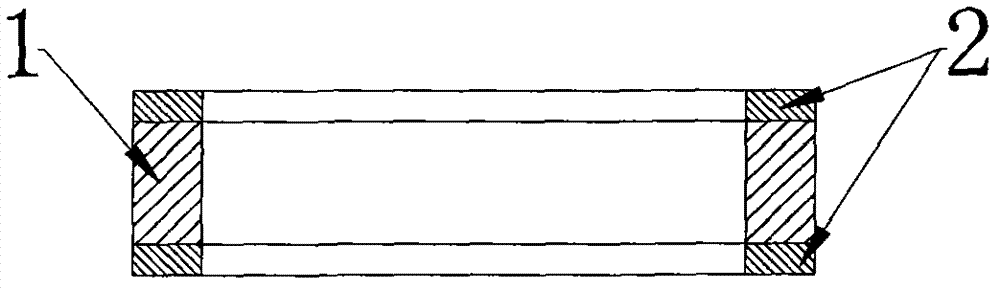

[0038] c Shaping and stamping of metal materials into metal gaskets 1;

[0039] d Ultrasonic treatment of metal gasket 1;

[0040] e Screening of flexible graphite 2, acidification and expansion at a temperature of 900-1100°C;

[0041] f Apply adhesive on the outer surface of the metal gasket 1 or the inner surface of the flexible graphite 2 or both ...

Embodiment 2

[0047] The manufacturing method of the metal composite flexible graphite gasket is according to the following steps:

[0048] a. Preheat the metal material at a temperature ≤ 200°C, put it into a heating furnace and raise the temperature to 1050-1150°C, and keep the temperature constant for 3 hours;

[0049] b Then take out the metal material from the heating furnace and quickly put it into the cooling water to cool down; after the above heat treatment process, the hardness of the metal material is reduced, and the tested performance parameters are shown in Table 2; figure 2 is the aging heat treatment curve of its metal material;

[0050] c Shaping and stamping of metal materials into metal gaskets 1;

[0051] d Ultrasonic treatment of metal gasket 1;

[0052] e Screening of flexible graphite 2, acidification and expansion at a temperature of 900-1100°C;

[0053] f Apply adhesive on the outer surface of the metal gasket 1 or the inner surface of the flexible graphite 2 or...

Embodiment 3

[0058] The manufacturing method of the metal composite flexible graphite gasket is according to the following steps:

[0059] a. Preheat the metal material at a temperature ≤ 200°C, put it into a heating furnace and raise the temperature to 1050-1150°C, and keep the temperature constant for 3 hours;

[0060] b Then take the metal material out of the heating furnace and put it into the cooling water to cool quickly; after the above heat treatment process, the hardness of the metal material is reduced, and the performance parameters are shown in Table 3 after testing. figure 2 is the aging heat treatment curve of its metal material;

[0061] c Shaping and stamping of metal materials into metal gaskets 1;

[0062] d Ultrasonic treatment of metal gasket 1;

[0063] e Screening of flexible graphite 2, acidification and expansion at a temperature of 900-1100°C;

[0064] f Apply adhesive on the outer surface of metal gasket 1 or the inner surface of flexible graphite 2 or both at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com